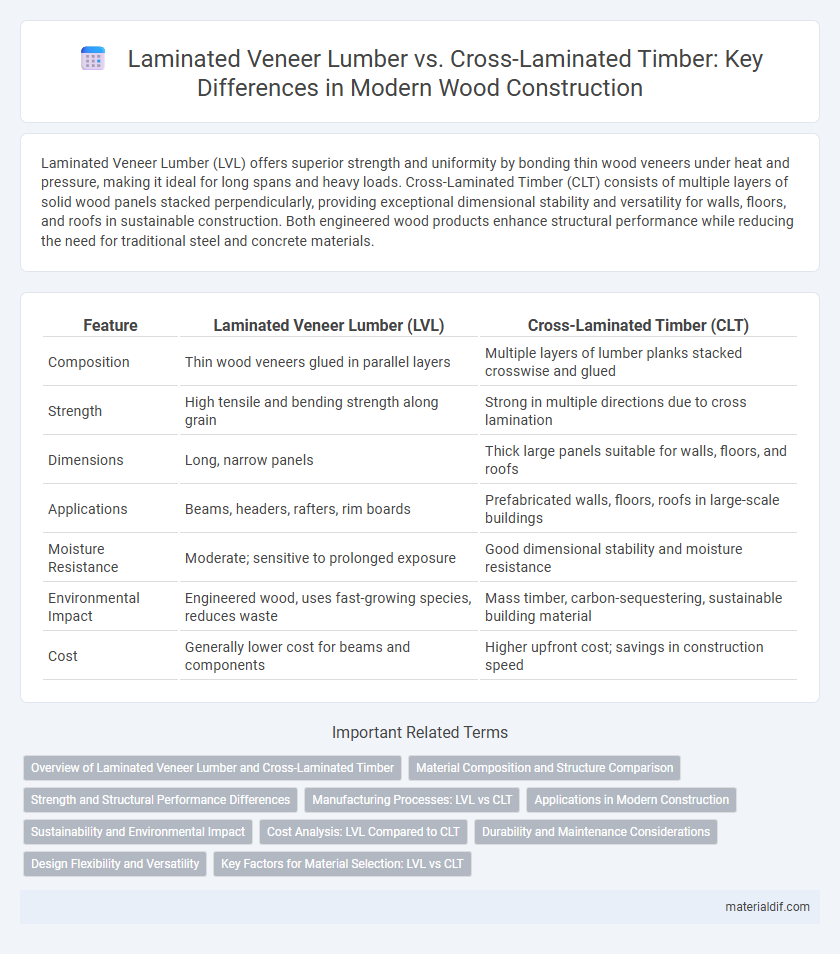

Laminated Veneer Lumber (LVL) offers superior strength and uniformity by bonding thin wood veneers under heat and pressure, making it ideal for long spans and heavy loads. Cross-Laminated Timber (CLT) consists of multiple layers of solid wood panels stacked perpendicularly, providing exceptional dimensional stability and versatility for walls, floors, and roofs in sustainable construction. Both engineered wood products enhance structural performance while reducing the need for traditional steel and concrete materials.

Table of Comparison

| Feature | Laminated Veneer Lumber (LVL) | Cross-Laminated Timber (CLT) |

|---|---|---|

| Composition | Thin wood veneers glued in parallel layers | Multiple layers of lumber planks stacked crosswise and glued |

| Strength | High tensile and bending strength along grain | Strong in multiple directions due to cross lamination |

| Dimensions | Long, narrow panels | Thick large panels suitable for walls, floors, and roofs |

| Applications | Beams, headers, rafters, rim boards | Prefabricated walls, floors, roofs in large-scale buildings |

| Moisture Resistance | Moderate; sensitive to prolonged exposure | Good dimensional stability and moisture resistance |

| Environmental Impact | Engineered wood, uses fast-growing species, reduces waste | Mass timber, carbon-sequestering, sustainable building material |

| Cost | Generally lower cost for beams and components | Higher upfront cost; savings in construction speed |

Overview of Laminated Veneer Lumber and Cross-Laminated Timber

Laminated Veneer Lumber (LVL) is an engineered wood product made by layering thin wood veneers with adhesives, offering high strength, uniformity, and dimensional stability for beams, headers, and rim boards. Cross-Laminated Timber (CLT) consists of multiple layers of solid-sawn lumber boards, stacked crosswise and glued, enhancing rigidity, load distribution, and structural performance in walls, floors, and roofs. Both LVL and CLT provide sustainable alternatives to traditional construction materials, with LVL specializing in long-span applications and CLT excelling in large-scale, prefabricated panel systems.

Material Composition and Structure Comparison

Laminated Veneer Lumber (LVL) consists of multiple thin wood veneers glued together with grain oriented in the same direction, providing high strength and stiffness along the grain. Cross-Laminated Timber (CLT) is composed of several layers of solid wood panels stacked crosswise at 90-degree angles, enhancing dimensional stability and load distribution in multiple directions. LVL excels in beam applications due to unidirectional grain alignment, while CLT offers superior performance in wall, floor, and roof panels through its cross-laminated structure.

Strength and Structural Performance Differences

Laminated Veneer Lumber (LVL) offers superior tensile strength and dimensional stability due to its thin wood veneers bonded with strong adhesives, making it ideal for long-span beams and headers. Cross-Laminated Timber (CLT) provides enhanced multi-directional strength and rigidity by stacking layers of lumber at right angles, resulting in excellent load distribution and resistance to shear forces. While LVL excels in linear strength applications, CLT is preferred for panelized construction requiring robust structural performance in multiple directions.

Manufacturing Processes: LVL vs CLT

Laminated Veneer Lumber (LVL) is manufactured by bonding thin wood veneers under heat and pressure, aligning the grain direction parallel to enhance strength and stiffness. Cross-Laminated Timber (CLT) consists of multiple layers of lumber boards stacked perpendicular to each other and glued, creating a solid wood panel with enhanced dimensional stability and load-bearing capacity. The LVL process emphasizes unidirectional strength for beams and headers, while CLT's cross lamination optimizes multi-directional structural performance in walls, floors, and roofs.

Applications in Modern Construction

Laminated Veneer Lumber (LVL) is predominantly used for structural framing, headers, and beams in residential and light commercial buildings due to its high strength-to-weight ratio. Cross-Laminated Timber (CLT) caters to larger-scale projects such as multi-story residential, commercial, and public buildings, offering exceptional dimensional stability and fire resistance. Both engineered wood products support sustainable construction by reducing reliance on steel and concrete, enhancing building efficiency and environmental performance.

Sustainability and Environmental Impact

Laminated Veneer Lumber (LVL) and Cross-Laminated Timber (CLT) both offer sustainable alternatives to traditional building materials by utilizing wood efficiently, yet CLT generally has a lower carbon footprint due to its larger use of solid wood panels that sequester more CO2. LVL production involves peeling and layering veneers, which optimizes wood fiber use but requires more adhesives and energy-intensive processes, potentially increasing environmental impact. CLT's cross-lamination technique enhances structural strength and durability, extending building life spans and reducing resource consumption over time, making it a superior choice for eco-friendly construction.

Cost Analysis: LVL Compared to CLT

Laminated Veneer Lumber (LVL) generally incurs lower material and fabrication costs compared to Cross-Laminated Timber (CLT) due to its simpler manufacturing process and smaller panel sizes. LVL offers cost advantages in projects requiring straight, uniform beams, while CLT's layered cross-grain construction typically results in higher prices driven by increased labor, machinery, and transport expenses. Economic feasibility of LVL versus CLT largely depends on project scale, structural requirements, and regional availability of raw materials and fabrication facilities.

Durability and Maintenance Considerations

Laminated Veneer Lumber (LVL) offers high durability due to its layered construction, resisting warping and splitting in structural applications, while requiring minimal maintenance compared to solid wood. Cross-Laminated Timber (CLT) provides exceptional dimensional stability and strength through cross-layered boards, with durability enhanced by proper sealing and protective coatings to prevent moisture infiltration. Both LVL and CLT demand routine inspection for joint integrity and surface protection, but CLT generally needs more vigilant maintenance in wet or exterior environments to sustain its performance and longevity.

Design Flexibility and Versatility

Laminated Veneer Lumber (LVL) offers superior design flexibility due to its ability to be fabricated into precise, custom shapes, ideal for beams and headers in complex architectural projects. Cross-Laminated Timber (CLT) provides versatility through large panel sizes that enable rapid construction and multi-story building applications, enhancing both structural performance and design possibilities. Both materials support innovative wood construction, with LVL excelling in linear load-bearing elements and CLT optimizing broader surface applications.

Key Factors for Material Selection: LVL vs CLT

Laminated Veneer Lumber (LVL) offers superior strength in the longitudinal direction, making it ideal for beams and headers requiring high load-bearing capacity, while Cross-Laminated Timber (CLT) provides enhanced dimensional stability and rigidity due to its crosswise layering, suitable for walls and floors. LVL's manufacturing process involves stacking thin wood veneers bonded with adhesives, resulting in a product with consistent density and fewer voids, whereas CLT panels are composed of several layers of lumber boards glued perpendicular to each other, optimizing structural performance in multiple directions. Key factors for material selection include load requirements, dimensional stability, panel size, and construction type, with LVL preferred for linear applications and CLT favored for large-scale, multi-directional structural components.

Laminated Veneer Lumber vs Cross-Laminated Timber Infographic

materialdif.com

materialdif.com