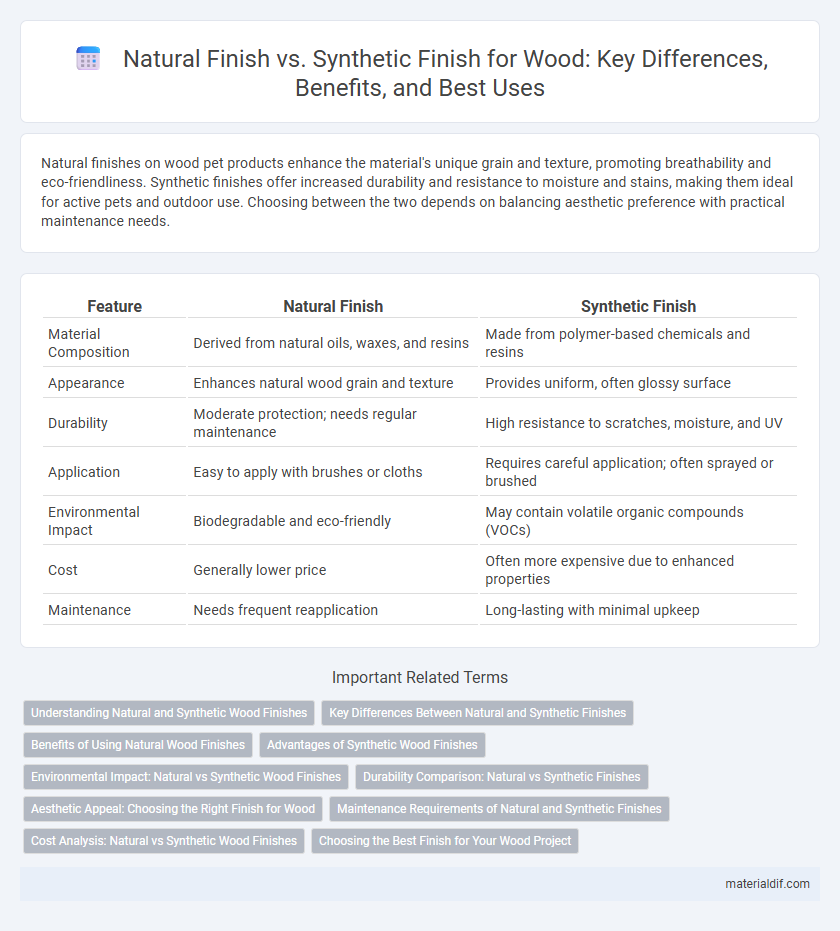

Natural finishes on wood pet products enhance the material's unique grain and texture, promoting breathability and eco-friendliness. Synthetic finishes offer increased durability and resistance to moisture and stains, making them ideal for active pets and outdoor use. Choosing between the two depends on balancing aesthetic preference with practical maintenance needs.

Table of Comparison

| Feature | Natural Finish | Synthetic Finish |

|---|---|---|

| Material Composition | Derived from natural oils, waxes, and resins | Made from polymer-based chemicals and resins |

| Appearance | Enhances natural wood grain and texture | Provides uniform, often glossy surface |

| Durability | Moderate protection; needs regular maintenance | High resistance to scratches, moisture, and UV |

| Application | Easy to apply with brushes or cloths | Requires careful application; often sprayed or brushed |

| Environmental Impact | Biodegradable and eco-friendly | May contain volatile organic compounds (VOCs) |

| Cost | Generally lower price | Often more expensive due to enhanced properties |

| Maintenance | Needs frequent reapplication | Long-lasting with minimal upkeep |

Understanding Natural and Synthetic Wood Finishes

Natural wood finishes, such as oils, waxes, and shellac, penetrate the wood to enhance its grain and provide a breathable protective layer that ages gracefully over time. Synthetic finishes, including polyurethane, acrylic, and epoxy, form a durable, moisture-resistant barrier on the wood's surface, offering higher resistance to scratches and chemicals. Choosing between natural and synthetic finishes depends on desired appearance, durability requirements, and maintenance preferences for the wood project.

Key Differences Between Natural and Synthetic Finishes

Natural finishes, such as oils and waxes, penetrate the wood to enhance its grain and maintain breathability, promoting a more organic appearance and feel. Synthetic finishes, including polyurethane and varnishes, form a protective layer on the wood surface that offers greater durability, resistance to moisture, and chemical exposure. Key differences lie in their application methods, longevity, maintenance requirements, and environmental impact, with natural finishes favoring eco-friendliness and synthetic finishes providing more robust protection.

Benefits of Using Natural Wood Finishes

Natural wood finishes enhance the wood's inherent beauty by highlighting its grain and texture while providing a breathable protective layer that prevents moisture damage without sealing in harmful chemicals. These finishes are eco-friendly, made from renewable resources like oils and waxes, which reduce environmental impact and improve indoor air quality by avoiding volatile organic compounds (VOCs). Using natural finishes also extends the lifespan of wood by nourishing it and allowing it to age gracefully, maintaining its durability and aesthetic appeal over time.

Advantages of Synthetic Wood Finishes

Synthetic wood finishes offer superior durability and resistance to moisture, UV rays, and chemicals compared to natural finishes. They provide a consistent, long-lasting protective layer that minimizes the frequency of reapplication and maintenance efforts. Many synthetic finishes enhance the wood's appearance by preserving color and preventing fading, making them ideal for both indoor and outdoor wooden surfaces.

Environmental Impact: Natural vs Synthetic Wood Finishes

Natural wood finishes, such as oils and waxes, typically have a lower environmental impact due to their biodegradable ingredients and minimal use of toxic chemicals, supporting better indoor air quality and easier disposal. Synthetic finishes often contain volatile organic compounds (VOCs) and petrochemical-based solvents that contribute to air pollution and pose health risks during application and disposal. Choosing natural finishes reduces reliance on fossil fuels and enhances sustainability by promoting renewable, eco-friendly sourcing of materials.

Durability Comparison: Natural vs Synthetic Finishes

Natural wood finishes, such as oils and waxes, penetrate the wood fibers, enhancing breathability but offering moderate durability against moisture and wear. Synthetic finishes, including polyurethane and epoxy, form a hard, protective layer that significantly improves resistance to scratches, chemicals, and water damage. For environments demanding long-lasting protection, synthetic finishes provide superior durability compared to natural finishes, though natural finishes maintain aesthetic appeal and easy maintenance.

Aesthetic Appeal: Choosing the Right Finish for Wood

Natural finishes enhance wood's organic grain and texture by allowing its inherent beauty to shine through, offering a warm, authentic look that evolves with age. Synthetic finishes provide a consistent, durable surface with a variety of vibrant colors and gloss levels, appealing to modern design preferences that demand low maintenance. Selecting between natural and synthetic finishes depends on desired aesthetic goals and the surrounding environment where the wood will be showcased.

Maintenance Requirements of Natural and Synthetic Finishes

Natural finishes on wood require regular reapplication of oils or waxes to maintain their protective layer and enhance the wood's appearance, often needing touch-ups every six to twelve months depending on exposure. Synthetic finishes such as polyurethane or acrylic offer a durable, water-resistant barrier that typically demands less frequent maintenance, requiring cleaning and occasional polishing to preserve their gloss and protection for several years. Natural finishes may be easier to repair with spot treatments, while synthetic finishes often require sanding and recoating for a seamless restoration.

Cost Analysis: Natural vs Synthetic Wood Finishes

Natural wood finishes often come with higher upfront costs due to expensive materials like oils and waxes but tend to offer long-term savings through easier repair and maintenance. Synthetic finishes such as polyurethane or lacquer usually have lower initial costs and provide durable, resistant surfaces that reduce the frequency of refinishing. Evaluating the total cost of ownership involves comparing the durability, maintenance frequency, and environmental impact associated with each finish type.

Choosing the Best Finish for Your Wood Project

Selecting the best finish for your wood project depends on the desired durability, appearance, and maintenance level. Natural finishes, such as oils and waxes, enhance the wood's grain and provide a warm, authentic look while allowing the wood to breathe and age gracefully. Synthetic finishes, including polyurethane and varnishes, offer superior protection against moisture, scratches, and UV damage, making them ideal for high-traffic or outdoor applications.

Natural Finish vs Synthetic Finish Infographic

materialdif.com

materialdif.com