Pressure-treated wood undergoes a chemical infusion process that significantly enhances its resistance to rot, decay, and insect damage, making it ideal for outdoor projects and structures exposed to moisture. Untreated wood maintains its natural appearance and is often preferred for indoor applications or where chemical exposure is a concern, but it lacks the durability needed for prolonged exposure to the elements. Selecting between pressure-treated and untreated wood depends on the specific environmental conditions and longevity requirements of the intended use.

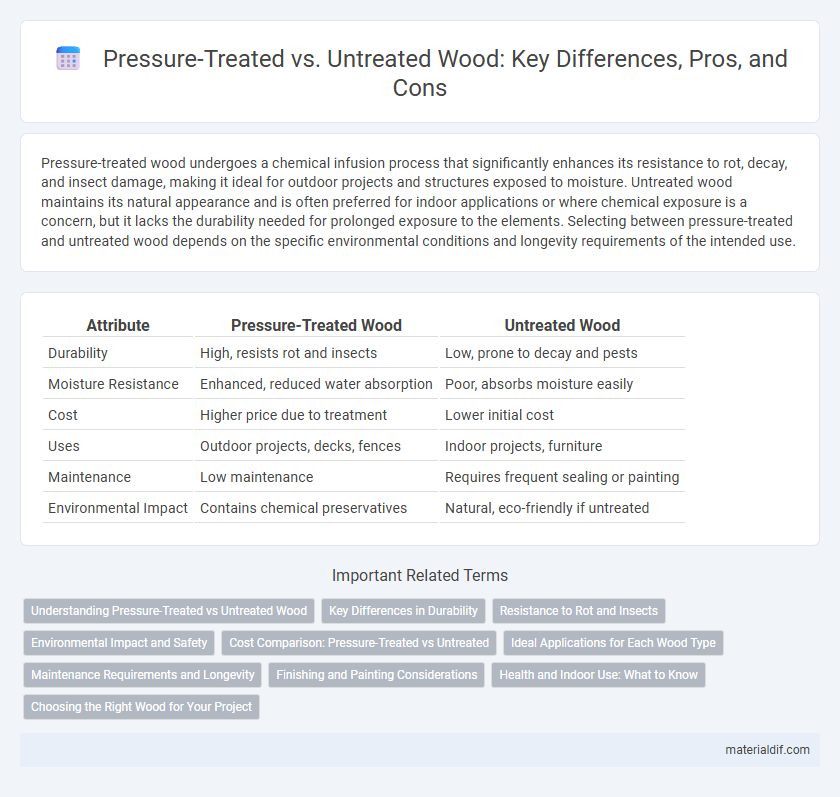

Table of Comparison

| Attribute | Pressure-Treated Wood | Untreated Wood |

|---|---|---|

| Durability | High, resists rot and insects | Low, prone to decay and pests |

| Moisture Resistance | Enhanced, reduced water absorption | Poor, absorbs moisture easily |

| Cost | Higher price due to treatment | Lower initial cost |

| Uses | Outdoor projects, decks, fences | Indoor projects, furniture |

| Maintenance | Low maintenance | Requires frequent sealing or painting |

| Environmental Impact | Contains chemical preservatives | Natural, eco-friendly if untreated |

Understanding Pressure-Treated vs Untreated Wood

Pressure-treated wood undergoes a chemical infusion process to resist rot, insects, and fungal decay, making it ideal for outdoor structures like decks and fences. Untreated wood lacks these preservatives, making it more susceptible to moisture damage and pests, thus better suited for indoor or short-term applications. Choosing between pressure-treated and untreated wood depends on environmental exposure, durability needs, and maintenance considerations.

Key Differences in Durability

Pressure-treated wood is infused with chemical preservatives that significantly enhance its resistance to decay, insects, and moisture, making it ideal for outdoor applications. Untreated wood lacks these protective treatments, resulting in lower durability and a higher likelihood of warping, rotting, or insect damage over time. The lifespan of pressure-treated wood typically extends beyond 15 years in exposed environments, whereas untreated wood may degrade within a few years under similar conditions.

Resistance to Rot and Insects

Pressure-treated wood is infused with chemical preservatives that significantly enhance its resistance to rot and insect damage, making it ideal for outdoor applications exposed to moisture and pests. Untreated wood lacks these protective chemicals, resulting in a higher susceptibility to fungal decay and termite infestation, which can severely compromise structural integrity over time. For projects requiring long-term durability in damp or pest-prone environments, pressure-treated wood offers a superior defense compared to untreated wood.

Environmental Impact and Safety

Pressure-treated wood contains chemical preservatives like chromated copper arsenate (CCA) or alkaline copper quaternary (ACQ) that can leach toxins into soil and water, posing environmental risks. Untreated wood is more biodegradable and poses fewer chemical hazards, making it a safer option for outdoor use near gardens or water sources. However, untreated wood may have a shorter lifespan and require more frequent replacement, which can impact sustainability over time.

Cost Comparison: Pressure-Treated vs Untreated

Pressure-treated wood typically costs 50-100% more than untreated wood due to the chemical infusion process that enhances durability and resistance to rot and insects. Untreated wood remains the more economical choice upfront but may incur higher maintenance and replacement costs over time in outdoor or moisture-prone environments. Investment in pressure-treated wood often results in long-term cost savings by reducing decay and extending the lifespan of wooden structures.

Ideal Applications for Each Wood Type

Pressure-treated wood is ideal for outdoor projects exposed to moisture, such as decks, fences, and playground equipment, due to its resistance to rot, insects, and decay. Untreated wood is best suited for indoor applications or areas shielded from direct contact with water, like furniture, interior trim, and cabinetry, where its natural appearance and ease of finishing are valued. Choosing the proper wood type based on exposure conditions ensures durability and performance over time.

Maintenance Requirements and Longevity

Pressure-treated wood resists rot, decay, and insect damage due to chemical preservatives, significantly extending its longevity and reducing maintenance frequency compared to untreated wood. Untreated wood requires regular sealing, staining, or painting to protect against moisture and pests, which increases upkeep and shortens its lifespan. Choosing pressure-treated wood improves durability and minimizes long-term maintenance costs in outdoor applications.

Finishing and Painting Considerations

Pressure-treated wood requires longer drying times before finishing or painting due to its higher moisture content and chemical preservatives, which can affect paint adhesion and durability. Untreated wood generally offers better paint adherence and smoother finishes but demands regular maintenance to prevent weathering and decay. Selecting the right primer and paint specifically designed for pressure-treated wood enhances longevity and protects against peeling and blistering.

Health and Indoor Use: What to Know

Pressure-treated wood contains chemical preservatives such as copper-based compounds that can off-gas potentially harmful fumes, making it less suitable for indoor use without proper sealing or ventilation. Untreated wood, free from chemical additives, poses fewer health risks and is generally preferred for indoor applications like furniture and flooring. Ensuring adequate finishes and moisture control further reduces the risk of mold and allergens in indoor environments.

Choosing the Right Wood for Your Project

Pressure-treated wood offers enhanced resistance to rot, insects, and weather, making it ideal for outdoor projects like decks, fences, and landscaping. Untreated wood, such as cedar or pine, provides a natural aesthetic and is preferred for interior applications or where chemical exposure is a concern. Understanding the specific environmental conditions and durability requirements of your project ensures the right wood choice for longevity and performance.

Pressure-treated vs Untreated Infographic

materialdif.com

materialdif.com