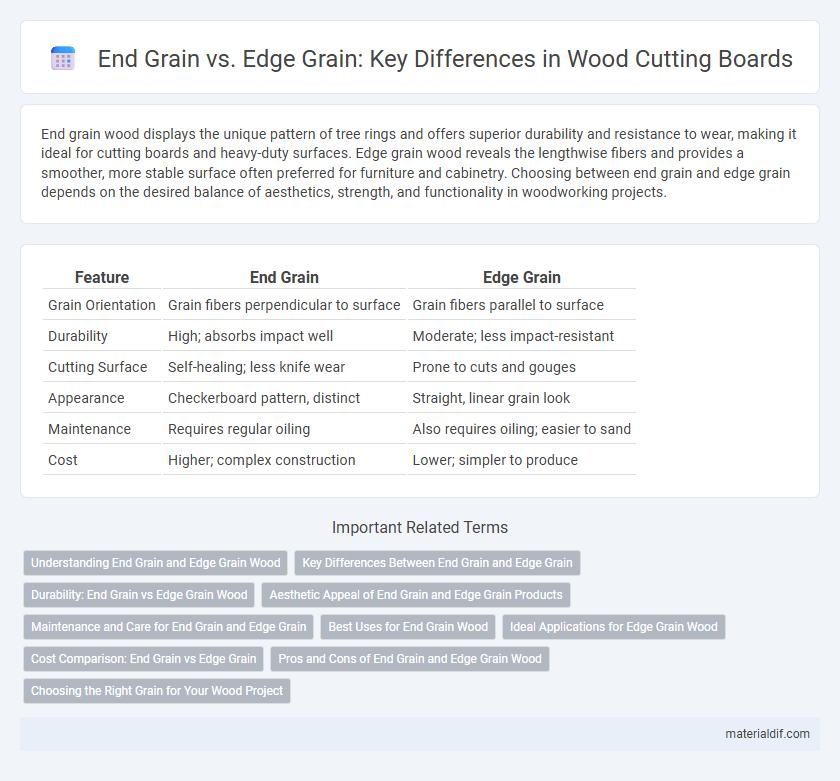

End grain wood displays the unique pattern of tree rings and offers superior durability and resistance to wear, making it ideal for cutting boards and heavy-duty surfaces. Edge grain wood reveals the lengthwise fibers and provides a smoother, more stable surface often preferred for furniture and cabinetry. Choosing between end grain and edge grain depends on the desired balance of aesthetics, strength, and functionality in woodworking projects.

Table of Comparison

| Feature | End Grain | Edge Grain |

|---|---|---|

| Grain Orientation | Grain fibers perpendicular to surface | Grain fibers parallel to surface |

| Durability | High; absorbs impact well | Moderate; less impact-resistant |

| Cutting Surface | Self-healing; less knife wear | Prone to cuts and gouges |

| Appearance | Checkerboard pattern, distinct | Straight, linear grain look |

| Maintenance | Requires regular oiling | Also requires oiling; easier to sand |

| Cost | Higher; complex construction | Lower; simpler to produce |

Understanding End Grain and Edge Grain Wood

End grain wood showcases the tree's growth rings in cross-section, offering superior absorption and durability for cutting boards and butcher blocks. Edge grain displays the wood's lengthwise fibers, providing a smoother surface with enhanced stability and resistance to warping in furniture making. Choosing between end grain and edge grain depends on the application's needs for wear resistance, aesthetics, and maintenance.

Key Differences Between End Grain and Edge Grain

End grain wood showcases the cut surface of the wood fibers, revealing patterns of growth rings, resulting in higher absorbency and superior shock resistance, making it ideal for cutting boards and butcher blocks. Edge grain wood displays the long, narrow edges of the growth rings, offering a straighter, more uniform grain appearance with greater structural stability and less warping potential. These key differences influence durability, aesthetics, and functionality, with end grain preferred for impact resistance and edge grain favored for smooth, linear grain patterns and dimensional consistency.

Durability: End Grain vs Edge Grain Wood

End grain wood demonstrates superior durability due to its fibers being oriented vertically, allowing it to absorb impacts and resist wear more effectively than edge grain wood. Edge grain wood, with fibers running parallel to the surface, offers moderate durability but is more prone to surface scratches and dents over time. Choosing end grain wood for cutting boards and heavy-use surfaces enhances longevity and withstands repeated use and knife marks better than edge grain alternatives.

Aesthetic Appeal of End Grain and Edge Grain Products

End grain wood showcases a unique, mosaic-like pattern with intricate growth rings and cell structures that enhance its visual richness and natural beauty. Edge grain presents long, linear grain lines that offer a sleek, uniform appearance ideal for modern and minimalist designs. Choosing between end grain and edge grain influences the aesthetic character of wood products, balancing complexity and subtlety in design elements.

Maintenance and Care for End Grain and Edge Grain

End grain wood requires more frequent sealing and oiling to maintain its moisture resistance due to its porous surface, which absorbs liquids more readily than edge grain. Edge grain wood, with its tighter grain pattern, is easier to clean and less prone to deep staining or warping, making regular wiping and occasional oiling sufficient for upkeep. Proper maintenance of both grain types involves using food-safe oils and keeping surfaces dry to prevent cracking and prolong lifespan.

Best Uses for End Grain Wood

End grain wood features fibers oriented vertically, making it highly durable and resistant to knife marks, ideal for cutting boards and butcher blocks. Its ability to self-heal minor cuts helps maintain a smooth surface, reducing wear over time in high-traffic kitchen environments. This grain structure also absorbs shock better, making it suitable for heavy-duty chopping and food preparation tasks.

Ideal Applications for Edge Grain Wood

Edge grain wood, known for its tight, straight grain pattern, offers greater stability and resistance to warping, making it ideal for cutting boards, tabletops, and furniture surfaces that require durability. This grain orientation enhances the wood's ability to withstand daily wear and moisture exposure, especially in kitchen environments. Its balanced hardness and smooth texture contribute to a fine finish, perfect for cabinetry and crafted wooden items demanding both aesthetic appeal and function.

Cost Comparison: End Grain vs Edge Grain

End grain wood tends to be more expensive than edge grain due to the labor-intensive cutting and finishing processes required to expose the unique cellular structure. Edge grain boards are generally more affordable as they involve simpler production methods and utilize more readily available sections of the tree. The cost difference also reflects the durability and aesthetic appeal, with end grain often preferred for high-end cutting boards and furniture applications.

Pros and Cons of End Grain and Edge Grain Wood

End grain wood offers superior durability and resistance to knife marks, making it ideal for cutting boards and butcher blocks, but it tends to be more expensive and harder to clean due to its porous surface. Edge grain wood provides a more stable, flat surface with less warping and smoother texture, making it suitable for furniture and flooring, although it is less resistant to deep cuts and dents compared to end grain. Both grain types impact the wood's performance and longevity based on project requirements and maintenance.

Choosing the Right Grain for Your Wood Project

Selecting between end grain and edge grain wood depends on the specific requirements of your project, as end grain offers superior durability and moisture resistance, ideal for cutting boards and butcher blocks. Edge grain provides a smoother surface with better stability and less movement, making it perfect for furniture and cabinetry. Understanding these grain types ensures optimal performance and longevity in woodworking projects.

End Grain vs Edge Grain Infographic

materialdif.com

materialdif.com