Edge grain wood features long, continuous fibers that provide better stability and a smooth, uniform surface ideal for pet furniture and toys. End grain wood exposes the cross-section of fibers, offering superior durability and resistance to wear, making it perfect for chew-resistant pet accessories. Choosing between edge grain and end grain depends on the balance between aesthetic appeal and long-lasting toughness required for your pet's needs.

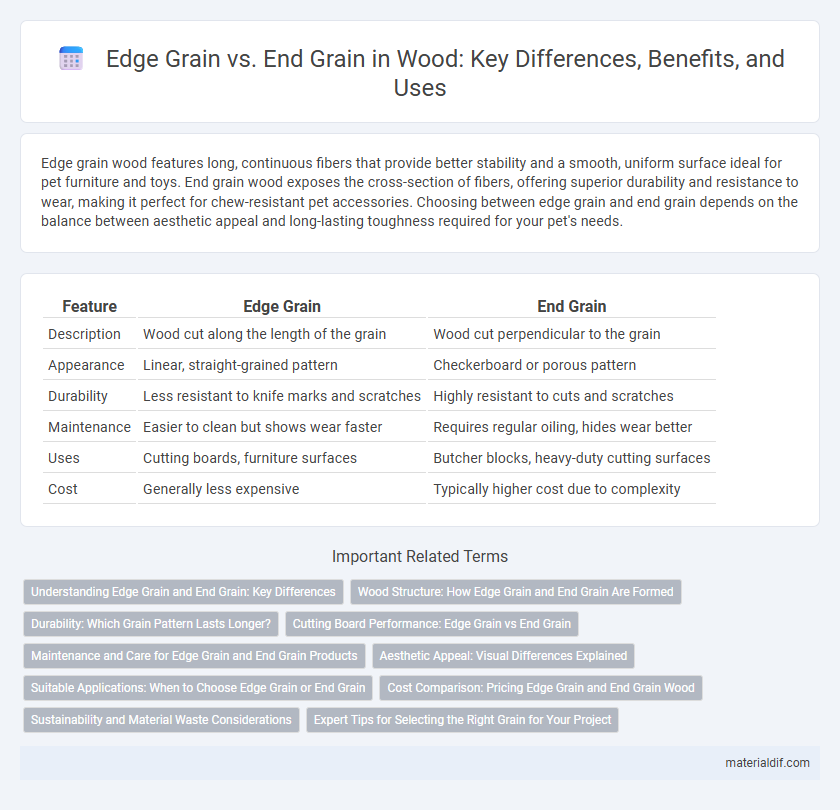

Table of Comparison

| Feature | Edge Grain | End Grain |

|---|---|---|

| Description | Wood cut along the length of the grain | Wood cut perpendicular to the grain |

| Appearance | Linear, straight-grained pattern | Checkerboard or porous pattern |

| Durability | Less resistant to knife marks and scratches | Highly resistant to cuts and scratches |

| Maintenance | Easier to clean but shows wear faster | Requires regular oiling, hides wear better |

| Uses | Cutting boards, furniture surfaces | Butcher blocks, heavy-duty cutting surfaces |

| Cost | Generally less expensive | Typically higher cost due to complexity |

Understanding Edge Grain and End Grain: Key Differences

Edge grain wood displays the long, vertical fibers of the tree, resulting in a smoother and more uniform appearance that is ideal for furniture and flooring due to its strength and stability. End grain wood exposes the tree's growth rings in a cross-section, offering superior shock absorption and resistance to wear, often used in cutting boards and butcher blocks. Recognizing these key differences helps in selecting the right wood grain for specific applications, balancing durability, aesthetics, and functionality.

Wood Structure: How Edge Grain and End Grain Are Formed

Edge grain wood is formed by cutting perpendicular to the growth rings, exposing the long fibers of the wood, which enhances strength and stability. End grain wood is created by slicing across the growth rings, revealing the wood's cellular structure and making it highly absorbent and resistant to impact. Understanding the orientation of grain helps determine a wood's suitability for various structural and aesthetic applications.

Durability: Which Grain Pattern Lasts Longer?

Edge grain wood, cut along the length of the growth rings, offers superior durability due to its density and resistance to wear, making it ideal for flooring and furniture. End grain, exposing the tree's growth rings vertically, absorbs impacts better but is more prone to scratches and dents over time. Although end grain may endure heavy use briefly, edge grain's structural integrity ensures longer-lasting performance in most applications.

Cutting Board Performance: Edge Grain vs End Grain

Edge grain cutting boards offer a smooth and durable surface ideal for everyday chopping, maintaining blade sharpness effectively due to the wood fibers running parallel to the cutting surface. End grain boards feature wood fibers oriented vertically, allowing the knife to sink between fibers, which enhances cutting board longevity and reduces wear on knife blades. While end grain boards are generally softer on knives and self-healing, edge grain boards provide greater stability and are often more affordable and easier to maintain.

Maintenance and Care for Edge Grain and End Grain Products

Edge grain wood surfaces require regular cleaning with mild soap and water and benefit from periodic oiling to prevent drying and maintain durability. End grain wood demands more intensive care, including frequent oiling and avoiding prolonged moisture exposure since its porous structure absorbs liquids quickly, increasing the risk of warping and cracking. Proper maintenance of both types extends their lifespan, with edge grain offering easier upkeep and end grain requiring careful attention to preserve its stability and appearance.

Aesthetic Appeal: Visual Differences Explained

Edge grain wood displays long, linear patterns from the side of the board, offering a sleek, uniform aesthetic ideal for furniture and cabinetry. End grain wood reveals intricate, circular growth rings and unique textures from the tree's cross-section, providing a striking, organic look often favored in cutting boards and decorative pieces. The contrasting visual appeal between edge grain's clean lines and end grain's complex patterns influences design choices based on desired style and surface character.

Suitable Applications: When to Choose Edge Grain or End Grain

Edge grain wood is ideal for furniture, flooring, and cabinetry due to its stability, smooth finish, and resistance to warping. End grain wood excels in cutting boards, butcher blocks, and workbenches because of its superior durability and ability to absorb knife impacts without significant damage. Choosing edge grain enhances aesthetic appeal and structural integrity, while end grain prioritizes longevity and surface resilience under heavy wear.

Cost Comparison: Pricing Edge Grain and End Grain Wood

Edge grain wood typically costs less than end grain wood due to differences in production complexity and material yield. End grain wood, prized for its durability and unique aesthetic, requires more intricate cutting and results in higher waste, leading to increased pricing. The price disparity can range from 20% to 50%, influenced by wood species and market demand.

Sustainability and Material Waste Considerations

Edge grain wood offers greater durability and less material waste due to its straightforward cutting process, making it a more sustainable option in woodworking projects. End grain wood, while prized for its unique aesthetics and superior shock absorption, often generates more offcuts and requires more complex processing, increasing material waste. Choosing edge grain wood aligns with eco-friendly practices by maximizing resource efficiency and minimizing waste during production.

Expert Tips for Selecting the Right Grain for Your Project

Edge grain wood offers superior stability and a smooth surface ideal for furniture and cabinetry, while end grain wood excels in durability and shock absorption, making it perfect for cutting boards and butcher blocks. Experts recommend choosing edge grain for projects where precision and a fine finish matter, and end grain when resistance to wear and self-healing properties are crucial. Evaluating the wood's intended use and maintenance requirements helps determine the optimal grain orientation for long-lasting results.

Edge grain vs End grain Infographic

materialdif.com

materialdif.com