Janka hardness measures the resistance of wood to denting and wear by determining the force required to embed a steel ball into the wood surface. Brinell hardness assesses the indentation resistance of materials, including wood, using a larger steel ball and higher force, providing a broader measure of surface durability. While both scales evaluate hardness, Janka hardness is more commonly used for wood species, making it essential for selecting flooring materials based on durability and wear resistance.

Table of Comparison

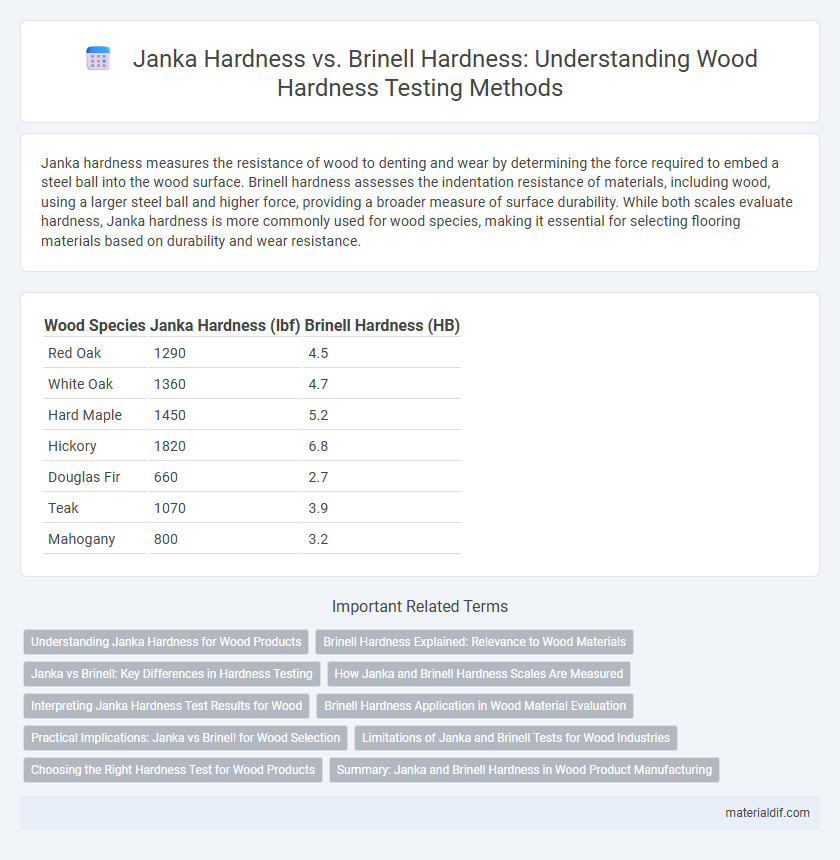

| Wood Species | Janka Hardness (lbf) | Brinell Hardness (HB) |

|---|---|---|

| Red Oak | 1290 | 4.5 |

| White Oak | 1360 | 4.7 |

| Hard Maple | 1450 | 5.2 |

| Hickory | 1820 | 6.8 |

| Douglas Fir | 660 | 2.7 |

| Teak | 1070 | 3.9 |

| Mahogany | 800 | 3.2 |

Understanding Janka Hardness for Wood Products

Janka hardness measures the resistance of wood to denting and wear by testing the force required to embed a 0.444-inch steel ball halfway into the wood surface, providing crucial data for selecting durable wood products. This test reflects practical durability for flooring and furniture, unlike Brinell hardness which is commonly used for metals and measures indentation under different conditions. Understanding Janka hardness helps manufacturers and consumers evaluate wood species' suitability for high-traffic areas and long-term use.

Brinell Hardness Explained: Relevance to Wood Materials

Brinell hardness measures the resistance of a material's surface to indentation using a steel ball, providing critical data on wood's durability under localized pressure. Unlike the Janka hardness test, which assesses the force needed to embed a steel ball halfway into wood, Brinell hardness evaluates broader surface hardness, essential for applications requiring wear resistance. This test's scoring system helps manufacturers and engineers select wood species with optimal strength properties for flooring, furniture, and structural uses.

Janka vs Brinell: Key Differences in Hardness Testing

Janka hardness measures wood's resistance to denting and wear by determining the force required to embed a 0.444-inch steel ball halfway into the wood, focusing specifically on wood materials. Brinell hardness assesses broader material hardness by pressing a 10 mm steel ball into the surface under a specific load, calculating hardness based on the indentation area, making it suitable for metals and other materials. The key difference lies in Janka's wood-specific test emphasizing surface dent resistance, while Brinell provides a more general hardness value applicable across various materials.

How Janka and Brinell Hardness Scales Are Measured

Janka hardness measures the resistance of wood to denting and wear by determining the force required to embed a 0.444-inch steel ball halfway into the wood surface. Brinell hardness assesses material hardness by applying a larger 10 mm steel ball under a specific load and measuring the diameter of the indentation left on the wood. Both scales quantify wood hardness but differ in ball size, load, and indentation measurement method, influencing suitability for various wood applications.

Interpreting Janka Hardness Test Results for Wood

Interpreting Janka hardness test results involves understanding the force required to embed a 0.444-inch steel ball halfway into wood, measured in pounds-force (lbf) or newtons (N). The Janka test specifically evaluates wood's resistance to wear and denting, making it ideal for flooring and furniture applications. Unlike Brinell hardness, which measures indentation on metals using larger balls and higher loads, Janka hardness provides more relevant data for wood's surface durability and impact resistance.

Brinell Hardness Application in Wood Material Evaluation

Brinell hardness testing offers a precise measurement of wood surface resistance by applying a calibrated steel ball under consistent pressure, making it valuable for assessing wear and durability in flooring and furniture applications. Unlike the Janka hardness test, which measures the force needed to embed a steel ball halfway into the wood, the Brinell method quantifies indentation size to evaluate material hardness more comprehensively. This technique provides engineers and manufacturers with reliable data to optimize wood selection for construction projects requiring enhanced load-bearing capacity and abrasion resistance.

Practical Implications: Janka vs Brinell for Wood Selection

Janka hardness measures wood's resistance to denting and wear by quantifying the force required to embed a steel ball, making it ideal for evaluating flooring durability. Brinell hardness, while primarily used for metals, can provide a broader understanding of wood surface resistance but lacks the nuanced detail relevant for wood-specific applications. Choosing wood based on Janka hardness ensures practical suitability for household and commercial use where impact resistance is critical.

Limitations of Janka and Brinell Tests for Wood Industries

The Janka hardness test measures the resistance of wood to denting and wear by embedding a steel ball into the wood surface, making it ideal for flooring applications but limited by its focus on surface hardness and inability to assess overall material strength. The Brinell hardness test, typically used for metals, involves pressing a larger steel ball under higher loads and provides more comprehensive data on material deformation but is less practical for wood due to its anisotropic and fibrous nature. Both tests fail to fully capture wood's variable properties such as grain direction, moisture content, and internal defects, posing challenges for accurate assessment in diverse wood industry applications.

Choosing the Right Hardness Test for Wood Products

The Janka hardness test measures the resistance of wood to denting and wear by quantifying the force required to embed a steel ball into its surface, making it essential for evaluating flooring durability. The Brinell hardness test, which uses a larger steel ball to assess indentation size under pressure, is more suitable for dense, industrial wood products that need to withstand heavy mechanical loads. Selecting the appropriate hardness test depends on the end-use of the wood product, with Janka favored for consumer applications like flooring and furniture, and Brinell preferred for structural components requiring precise load-bearing assessments.

Summary: Janka and Brinell Hardness in Wood Product Manufacturing

Janka hardness measures the resistance of wood to denting and wear by determining the force required to embed a steel ball into the wood surface, making it crucial for assessing flooring durability. Brinell hardness quantifies wood's resistance to indentation through a larger steel ball under a heavier load, providing insight into overall material strength for structural applications. Manufacturers rely on the Janka test to select wood species for high-traffic products, while Brinell hardness guides decisions in load-bearing wood products, optimizing performance and longevity.

Janka hardness vs Brinell hardness Infographic

materialdif.com

materialdif.com