Heat-treated wood undergoes a high-temperature process that enhances its durability and resistance to decay without chemicals, making it eco-friendly and ideal for indoor use. Pressure-treated wood is infused with chemical preservatives under high pressure to protect against rot, insects, and weather, suited for outdoor applications requiring long-term exposure. Understanding the distinct treatment methods helps choose the right wood for specific environmental needs and project longevity.

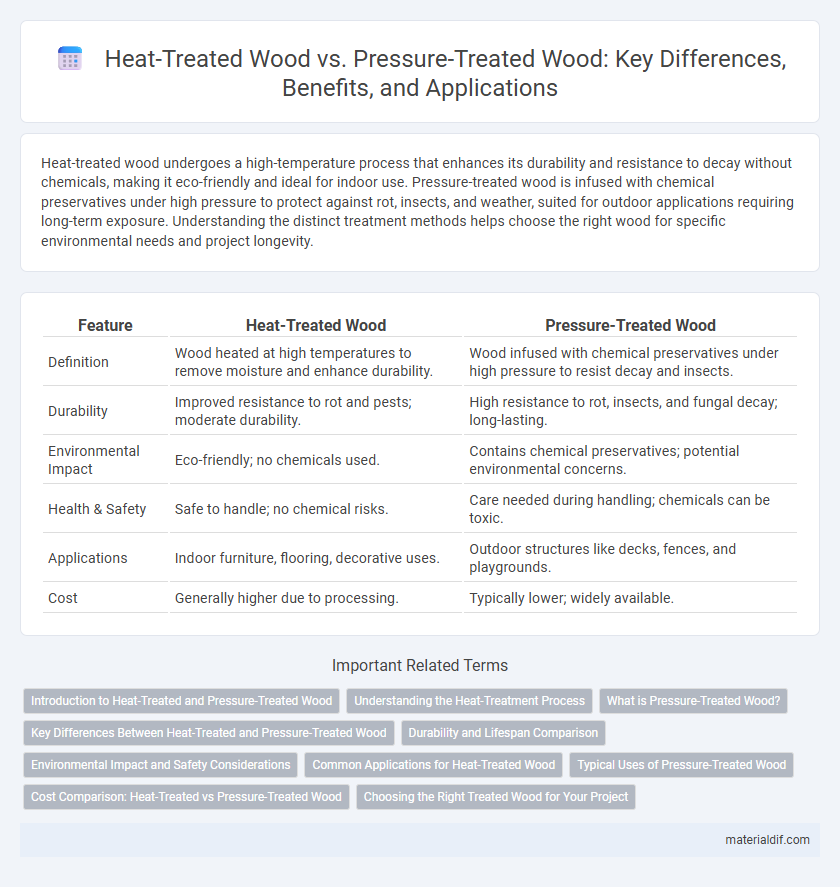

Table of Comparison

| Feature | Heat-Treated Wood | Pressure-Treated Wood |

|---|---|---|

| Definition | Wood heated at high temperatures to remove moisture and enhance durability. | Wood infused with chemical preservatives under high pressure to resist decay and insects. |

| Durability | Improved resistance to rot and pests; moderate durability. | High resistance to rot, insects, and fungal decay; long-lasting. |

| Environmental Impact | Eco-friendly; no chemicals used. | Contains chemical preservatives; potential environmental concerns. |

| Health & Safety | Safe to handle; no chemical risks. | Care needed during handling; chemicals can be toxic. |

| Applications | Indoor furniture, flooring, decorative uses. | Outdoor structures like decks, fences, and playgrounds. |

| Cost | Generally higher due to processing. | Typically lower; widely available. |

Introduction to Heat-Treated and Pressure-Treated Wood

Heat-treated wood undergoes a controlled heating process at temperatures between 180degC and 230degC, altering its chemical composition to enhance durability and resistance to decay without the use of chemicals. Pressure-treated wood is infused with chemical preservatives under high pressure, providing protection against insects, rot, and fungal decay, making it ideal for outdoor and structural applications. Both methods significantly improve wood longevity but differ in environmental impact and suitability depending on the intended use.

Understanding the Heat-Treatment Process

Heat-treated wood undergoes a controlled heating process, typically between 160degC and 220degC, in the absence of oxygen to enhance its durability and resistance to decay. This thermal modification reduces the wood's moisture content and alters its chemical structure, improving dimensional stability and resistance to biological deterioration without the use of chemicals. Unlike pressure-treated wood, which is impregnated with preservatives, heat-treated wood offers an eco-friendly alternative with improved resistance to rot and insects through a natural, non-toxic treatment process.

What is Pressure-Treated Wood?

Pressure-treated wood is lumber infused with chemical preservatives under high pressure to protect against rot, insects, and fungal decay, making it ideal for outdoor construction. This treatment extends the wood's durability in harsh environments such as decks, fences, and playgrounds. Compared to heat-treated wood, pressure-treated wood offers enhanced resistance to moisture and biological deterioration.

Key Differences Between Heat-Treated and Pressure-Treated Wood

Heat-treated wood undergoes a thermal modification process that enhances its durability and resistance to decay without the use of chemicals, making it environmentally friendly and ideal for indoor applications. Pressure-treated wood is infused with chemical preservatives under high pressure, providing robust protection against rot, insects, and weathering, often preferred for outdoor construction and structural uses. The key difference lies in their treatment methods and intended applications, with heat treatment improving stability and appearance, while pressure treatment maximizes longevity in harsh environments.

Durability and Lifespan Comparison

Heat-treated wood undergoes a thermal process that enhances its durability by reducing moisture content and increasing resistance to decay and insect damage, typically lasting 20 to 25 years in outdoor applications. Pressure-treated wood is infused with chemical preservatives under high pressure, offering superior protection against rot, fungi, and termites with a lifespan often exceeding 40 years, especially in ground contact. The choice between heat-treated and pressure-treated wood depends on the required durability for specific projects, balancing natural treatment benefits against chemical resistance and longevity.

Environmental Impact and Safety Considerations

Heat-treated wood undergoes a chemical-free process using high temperatures to eliminate pests and pathogens, resulting in an eco-friendly material with lower environmental impact compared to pressure-treated wood, which relies on chemical preservatives that may leach into soil and water. Heat-treated wood is safer for indoor use and contact with humans, as it avoids toxic substances like chromated copper arsenate (CCA) commonly found in pressure-treated wood. Choosing heat-treated wood supports sustainable forestry practices and reduces exposure to harmful chemicals, promoting healthier ecosystems and safer construction environments.

Common Applications for Heat-Treated Wood

Heat-treated wood is commonly used in indoor applications such as flooring, furniture, and cabinetry due to its enhanced durability and resistance to pests without the use of chemicals. It is also favored in saunas and other environments requiring moisture stability and reduced risk of fungal growth. Unlike pressure-treated wood, heat-treated wood is often selected for projects prioritizing natural preservation methods and indoor air quality.

Typical Uses of Pressure-Treated Wood

Pressure-treated wood is commonly used for outdoor projects requiring enhanced durability and resistance to moisture, insects, and decay, such as decks, fences, and utility poles. Its treatment process infuses chemical preservatives deep into the wood fibers, making it ideal for ground contact and structural applications exposed to harsh environmental conditions. Builders prefer pressure-treated wood for foundations, retaining walls, and playground equipment to ensure long-lasting performance under stress.

Cost Comparison: Heat-Treated vs Pressure-Treated Wood

Heat-treated wood typically costs more than pressure-treated wood due to its specialized thermal modification process, which enhances durability and resistance to decay without chemical additives. Pressure-treated wood is generally more affordable, relying on chemical preservatives infused under high pressure to improve longevity, making it a cost-effective choice for outdoor applications. Long-term maintenance expenses may be lower for heat-treated wood as it resists warping and moisture damage better, potentially offsetting its higher initial investment.

Choosing the Right Treated Wood for Your Project

Heat-treated wood undergoes a high-temperature process that enhances durability and resistance to decay without chemicals, making it ideal for indoor use and eco-friendly projects. Pressure-treated wood is infused with chemical preservatives under pressure, providing superior protection against insects, fungi, and moisture, suitable for outdoor applications like decks and fences. Selecting the right treated wood depends on exposure conditions, desired longevity, and environmental considerations specific to your project.

Heat-Treated Wood vs Pressure-Treated Wood Infographic

materialdif.com

materialdif.com