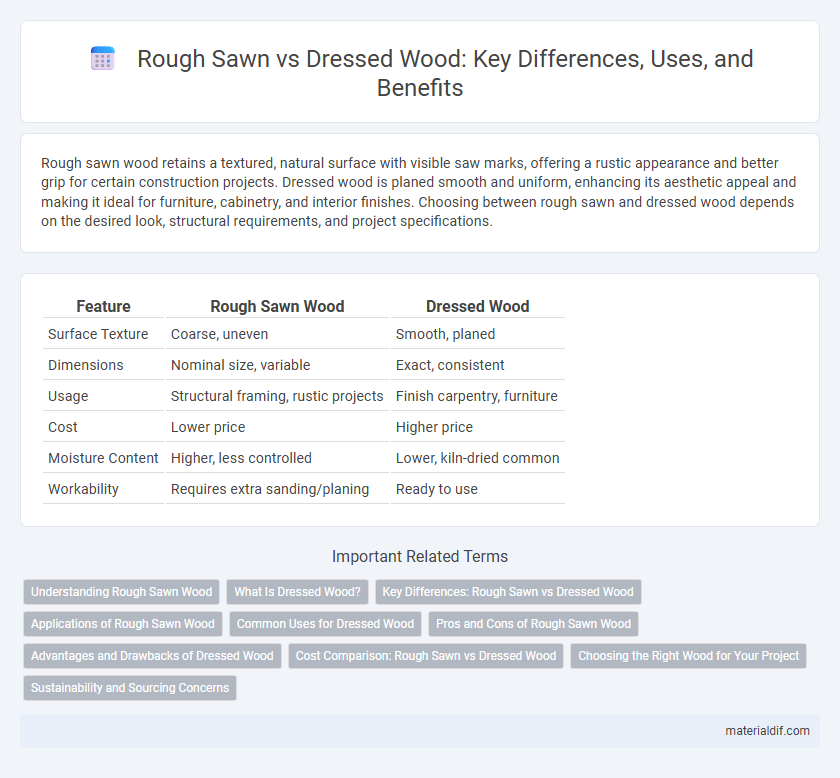

Rough sawn wood retains a textured, natural surface with visible saw marks, offering a rustic appearance and better grip for certain construction projects. Dressed wood is planed smooth and uniform, enhancing its aesthetic appeal and making it ideal for furniture, cabinetry, and interior finishes. Choosing between rough sawn and dressed wood depends on the desired look, structural requirements, and project specifications.

Table of Comparison

| Feature | Rough Sawn Wood | Dressed Wood |

|---|---|---|

| Surface Texture | Coarse, uneven | Smooth, planed |

| Dimensions | Nominal size, variable | Exact, consistent |

| Usage | Structural framing, rustic projects | Finish carpentry, furniture |

| Cost | Lower price | Higher price |

| Moisture Content | Higher, less controlled | Lower, kiln-dried common |

| Workability | Requires extra sanding/planing | Ready to use |

Understanding Rough Sawn Wood

Rough sawn wood, characterized by its coarse texture and uneven surface, is cut directly from logs using large saw blades without additional smoothing processes. This type of wood retains its natural edges and is often preferred for rustic construction and outdoor projects due to its durability and cost-effectiveness. Its higher moisture content compared to dressed wood affects shrinkage and requires careful seasoning before use in fine woodworking.

What Is Dressed Wood?

Dressed wood refers to lumber that has been planed and smoothed to achieve uniform thickness and a refined surface, making it ideal for visible applications like furniture and interior trim. This process removes rough saw marks, splinters, and irregularities, improving both the appearance and dimensional accuracy of the wood. Dressed wood is preferred in construction and woodworking projects where aesthetics and precise fitting are critical.

Key Differences: Rough Sawn vs Dressed Wood

Rough sawn wood features a coarse texture with visible saw marks and maintains its natural dimensions, offering superior grip for construction but requiring extra finishing. Dressed wood undergoes planing and smoothing processes, resulting in a uniform, polished surface ideal for furniture and interior applications. The key differences lie in surface texture, dimensional accuracy, and suitability for specific uses, with rough sawn wood favored for structural purposes and dressed wood preferred for aesthetic finishes.

Applications of Rough Sawn Wood

Rough sawn wood, characterized by its coarse texture and natural edges, is commonly used in applications such as rustic furniture, outdoor fencing, and construction framing where aesthetic appeal and structural strength are prioritized over smooth finishes. Its superior grip and resistance to warping make it ideal for landscaping projects, retaining walls, and agricultural buildings. The cost-effectiveness of rough sawn lumber also makes it a preferred choice for large-scale industrial and commercial timber framing.

Common Uses for Dressed Wood

Dressed wood, also known as planed wood, is commonly used in furniture making, cabinetry, and interior trim due to its smooth surface and precise dimensions. Its finished texture reduces the need for sanding and allows for easier painting or staining, making it ideal for visible applications. Structural projects like flooring and paneling often rely on dressed wood to achieve aesthetic appeal alongside durability.

Pros and Cons of Rough Sawn Wood

Rough sawn wood retains its natural texture and thickness, providing superior grip and a rustic aesthetic favored in outdoor and structural projects. It is more affordable and less processed compared to dressed wood, but its uneven surface can be challenging to work with and may require additional finishing for indoor use. Moisture retention in rough sawn wood often leads to higher susceptibility to warping and splitting if not properly treated.

Advantages and Drawbacks of Dressed Wood

Dressed wood offers a smooth, uniform surface ideal for precise construction and finishing, enhancing aesthetic appeal and reducing the need for additional sanding or shaping. Its consistent dimensions improve structural accuracy and fit, which benefits cabinetry, flooring, and furniture making. However, dressed wood can be more expensive and may retain moisture longer than rough sawn wood, potentially leading to warping or decay if not properly treated.

Cost Comparison: Rough Sawn vs Dressed Wood

Rough sawn wood typically costs 20-30% less than dressed wood due to minimal processing and finishing requirements. Dressed wood undergoes planing and sanding to achieve smooth surfaces, increasing labor and machinery expenses that raise its price. For budget-conscious projects, rough sawn wood offers significant savings while dressed wood suits applications demanding refined aesthetics and precision.

Choosing the Right Wood for Your Project

Rough sawn wood retains its natural, textured surface, offering superior grip and a rustic aesthetic ideal for outdoor projects or structural framing where appearance is secondary. Dressed wood is planed and smoothed, providing a uniform finish perfect for furniture, cabinetry, and interior applications that demand precise dimensions and refined surfaces. Selecting the appropriate wood depends on project requirements such as structural strength, appearance, and ease of finishing.

Sustainability and Sourcing Concerns

Rough sawn wood retains its natural texture and requires less processing, reducing energy consumption and waste compared to dressed wood, which undergoes planing and sanding. Sustainable sourcing for both types demands certification from organizations like FSC or PEFC to ensure responsible forest management and traceability. Choosing rough sawn wood from certified sources minimizes environmental impact and supports biodiversity by promoting selective harvesting and reducing chemical treatments.

Rough Sawn vs Dressed Wood Infographic

materialdif.com

materialdif.com