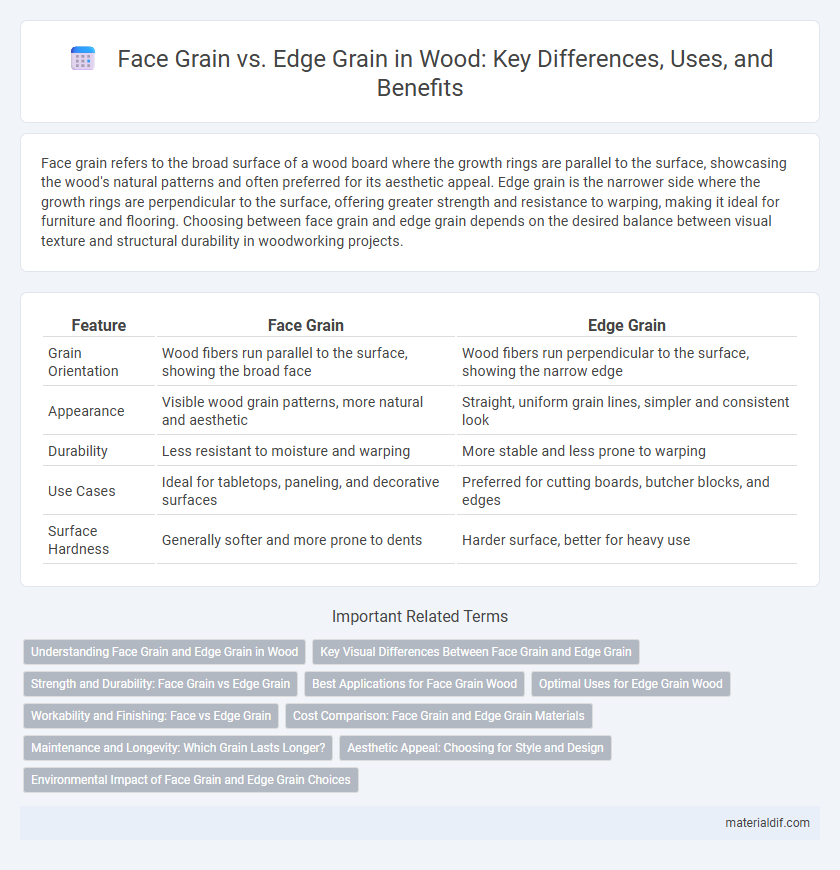

Face grain refers to the broad surface of a wood board where the growth rings are parallel to the surface, showcasing the wood's natural patterns and often preferred for its aesthetic appeal. Edge grain is the narrower side where the growth rings are perpendicular to the surface, offering greater strength and resistance to warping, making it ideal for furniture and flooring. Choosing between face grain and edge grain depends on the desired balance between visual texture and structural durability in woodworking projects.

Table of Comparison

| Feature | Face Grain | Edge Grain |

|---|---|---|

| Grain Orientation | Wood fibers run parallel to the surface, showing the broad face | Wood fibers run perpendicular to the surface, showing the narrow edge |

| Appearance | Visible wood grain patterns, more natural and aesthetic | Straight, uniform grain lines, simpler and consistent look |

| Durability | Less resistant to moisture and warping | More stable and less prone to warping |

| Use Cases | Ideal for tabletops, paneling, and decorative surfaces | Preferred for cutting boards, butcher blocks, and edges |

| Surface Hardness | Generally softer and more prone to dents | Harder surface, better for heavy use |

Understanding Face Grain and Edge Grain in Wood

Face grain in wood refers to the broad, flat surface of a lumber piece where the growth rings are typically visible, showcasing the wood's natural pattern and texture prominently. Edge grain, on the other hand, is the narrower, smoother side of the wood, often revealing a straighter, linear grain pattern due to the alignment of the growth rings along the board's thickness. Understanding these grain orientations is crucial for woodworking projects as face grain offers aesthetic appeal and edge grain provides enhanced stability and strength.

Key Visual Differences Between Face Grain and Edge Grain

Face grain showcases the broad, flat surface of wood, highlighting prominent, wide growth rings and a smooth texture that accentuates the wood's natural patterns and color variations. Edge grain reveals the narrow, vertical side of the wood, displaying tighter, straighter lines with less visible growth rings and a more uniform appearance. These visual distinctions influence both the aesthetic appeal and the durability of wooden furniture and flooring choices.

Strength and Durability: Face Grain vs Edge Grain

Face grain wood displays its natural grain pattern and offers moderate strength and durability, making it ideal for aesthetic surfaces and light-duty applications. Edge grain wood, cut perpendicular to the growth rings, provides superior strength and durability due to its denser fiber arrangement, which resists warping and cracking better than face grain. This makes edge grain the preferred choice for heavy-use items like cutting boards and butcher blocks where long-term durability is essential.

Best Applications for Face Grain Wood

Face grain wood, harvested from the plank's broadest surface, offers a visually appealing pattern with pronounced grain lines, making it ideal for furniture surfaces and cabinetry where aesthetics are paramount. Its dimensional stability and resistance to warping suit applications like tabletops and decorative panels that require both beauty and durability. Compared to edge grain, face grain wood displays more prominent grain but is less resistant to wear, best reserved for areas emphasizing visual impact over heavy use.

Optimal Uses for Edge Grain Wood

Edge grain wood, characterized by the growth rings oriented vertically, offers enhanced stability and resistance to warping, making it ideal for cutting boards and butcher blocks. Its balanced hardness and smoother surface reduce knife dulling and provide a durable work surface in kitchens and workshops. This grain orientation also excels in furniture components that require dimensional stability under stress.

Workability and Finishing: Face vs Edge Grain

Face grain wood offers superior workability due to its broader, more uniform fibers, making it easier to plane and sand for a smooth finish. Edge grain displays tighter, denser fibers that provide enhanced durability and a more pronounced grain pattern, ideal for structural work and detailed finishing. Both grains require careful finishing techniques; face grain absorbs stains and finishes more evenly, while edge grain demands precision to prevent blotching and achieve a consistent appearance.

Cost Comparison: Face Grain and Edge Grain Materials

Face grain wood typically costs more due to its aesthetically pleasing, pronounced grain patterns and easier workability. Edge grain wood is generally more affordable, offering greater durability and resistance to warping but with less visual appeal. Choosing between face grain and edge grain materials depends on balancing budget constraints with desired appearance and performance.

Maintenance and Longevity: Which Grain Lasts Longer?

Face grain, with its wide, flat surface, generally offers better resistance to wear and easier maintenance due to fewer exposed end fibers that can absorb moisture. Edge grain, characterized by narrower, vertical grain lines, tends to be more durable and less prone to warping over time, making it a preferred choice for longevity in high-use wooden surfaces. Proper sealing and regular care significantly extend the lifespan of both face grain and edge grain wood products.

Aesthetic Appeal: Choosing for Style and Design

Face grain showcases the natural patterns of wood, offering distinctive, intricate designs that enhance the aesthetic appeal of furniture and flooring. Edge grain presents a more uniform, linear texture, providing a sleek and modern look preferred in minimalist design styles. Selecting between face grain and edge grain depends on the desired visual impact and the overall style of the interior space.

Environmental Impact of Face Grain and Edge Grain Choices

Face grain wood, with its wider growth rings and natural durability, often requires less chemical treatment and finishes, reducing environmental toxins compared to edge grain wood. Edge grain wood, harvested from the trunk's inner layers, generally boasts denser fibers and enhanced strength, leading to longer product lifespans and less frequent replacement, which can lower overall resource consumption. Choosing face grain or edge grain affects not only aesthetic and structural qualities but also the carbon footprint and sustainability practices associated with wood sourcing and processing.

Face Grain vs Edge Grain Infographic

materialdif.com

materialdif.com