Cuprammonium rayon offers a finer, silk-like texture due to its production through the cuprammonium process, which uses copper and ammonia to dissolve cellulose, resulting in a smoother fiber compared to viscose rayon. Viscose rayon, produced by treating cellulose with carbon disulfide and sodium hydroxide, tends to be coarser and more affordable, making it widely used in textiles requiring durability and absorbency. Both fibers are biodegradable and breathable, but cuprammonium rayon is prized for its lustrous sheen and softness, while viscose is favored for versatility and cost-effectiveness.

Table of Comparison

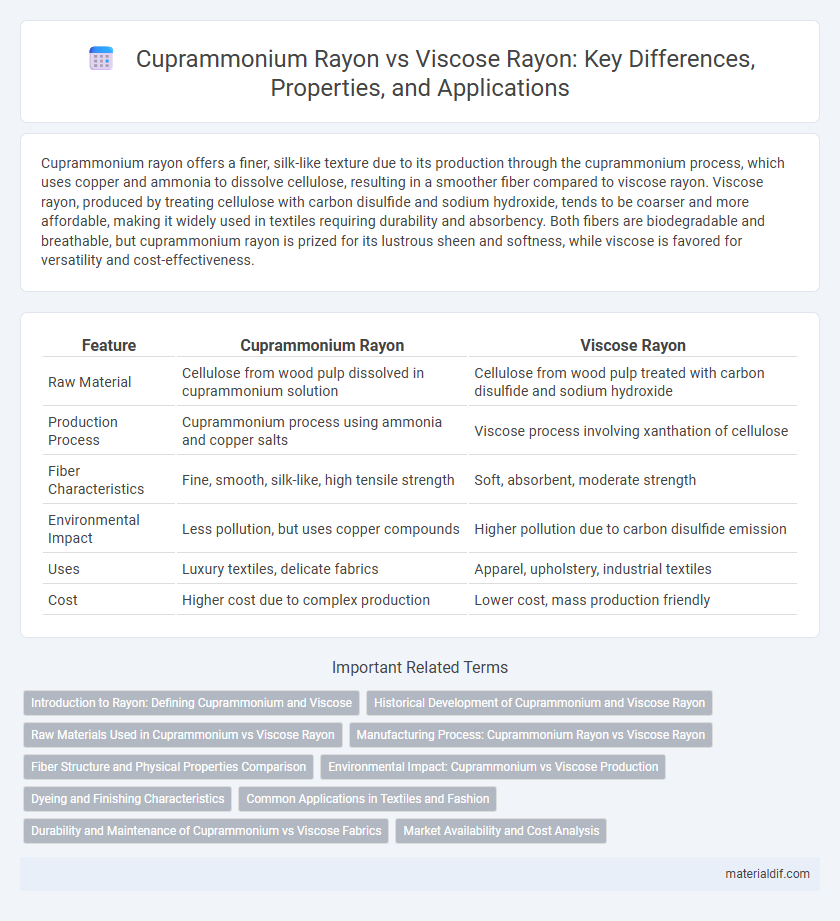

| Feature | Cuprammonium Rayon | Viscose Rayon |

|---|---|---|

| Raw Material | Cellulose from wood pulp dissolved in cuprammonium solution | Cellulose from wood pulp treated with carbon disulfide and sodium hydroxide |

| Production Process | Cuprammonium process using ammonia and copper salts | Viscose process involving xanthation of cellulose |

| Fiber Characteristics | Fine, smooth, silk-like, high tensile strength | Soft, absorbent, moderate strength |

| Environmental Impact | Less pollution, but uses copper compounds | Higher pollution due to carbon disulfide emission |

| Uses | Luxury textiles, delicate fabrics | Apparel, upholstery, industrial textiles |

| Cost | Higher cost due to complex production | Lower cost, mass production friendly |

Introduction to Rayon: Defining Cuprammonium and Viscose

Cuprammonium rayon is a type of regenerated cellulose fiber produced by dissolving cellulose in a cuprammonium solution, resulting in fine, smooth fibers with a silk-like texture. Viscose rayon, derived from cellulose treated with carbon disulfide and alkali, is known for its versatility, softness, and breathability, making it widely used in textiles. Both fibers belong to the rayon family but differ significantly in their manufacturing processes and fiber properties, influencing their applications and performance in fabric production.

Historical Development of Cuprammonium and Viscose Rayon

Cuprammonium rayon, developed in the late 19th century by chemist Max Fremery and Eduard Vogel, was the first regenerated cellulose fiber produced using a copper-ammonia solution to dissolve cotton waste. Viscose rayon emerged shortly after in 1892, invented by Charles Frederick Cross, Edward John Bevan, and Clayton Beadle, utilizing the xanthation of cellulose to create a viscous solution, which revolutionized large-scale rayon production. The historical development of cuprammonium rayon laid foundational chemical processes, while viscose rayon's scalable and cost-effective method established it as the dominant regenerated cellulose fiber globally.

Raw Materials Used in Cuprammonium vs Viscose Rayon

Cuprammonium rayon is produced using highly purified cellulose dissolved in a cuprammonium solution, typically derived from cotton linters, which provides fine, smooth fibers. Viscose rayon, on the other hand, involves chemically treating wood pulp or bamboo cellulose with sodium hydroxide and carbon disulfide to create a viscous solution before regeneration. The differing raw materials and chemical processes heavily influence the fiber's texture, strength, and environmental impact.

Manufacturing Process: Cuprammonium Rayon vs Viscose Rayon

Cuprammonium rayon is produced by dissolving cellulose in a cuprammonium solution, which involves treating cellulose with copper salts and ammonia to create a smooth, fine fiber. Viscose rayon manufacturing requires chemically treating cellulose with sodium hydroxide and carbon disulfide to form viscose solution, which is then regenerated into fibers through acid baths. The cuprammonium process yields finer, silk-like fibers, while viscose manufacturing is more complex and involves harsher chemicals.

Fiber Structure and Physical Properties Comparison

Cuprammonium rayon features a finer, smoother fiber structure with a more uniform diameter compared to viscose rayon, resulting in a silk-like texture and higher tensile strength. Viscose rayon fibers exhibit a more irregular surface with a hollow, ribbon-like cross-section that enhances moisture absorption but reduces durability. The denser, more compact molecular arrangement in cuprammonium rayon contributes to its superior luster and better dye affinity relative to the more porous viscose fibers.

Environmental Impact: Cuprammonium vs Viscose Production

Cuprammonium rayon production involves using copper and ammonia, which can release toxic effluents if not properly managed, posing significant environmental hazards. Viscose rayon manufacturing relies heavily on carbon disulfide, a hazardous chemical contributing to air and water pollution, making its environmental footprint notably high. Sustainable alternatives and advanced wastewater treatment technologies are essential to mitigate the ecological damage of both fibers' production processes.

Dyeing and Finishing Characteristics

Cuprammonium rayon exhibits superior dye uptake due to its fine filament structure, resulting in brighter and more even coloration compared to viscose rayon. Viscose rayon, with its thicker fiber cross-section, tends to absorb dyes more slowly but offers a wider range of dye compatibility, particularly with reactive and direct dyes. In finishing, cuprammonium rayon responds better to processes like mercerization, enhancing luster and softness, while viscose rayon is more versatile for mechanical finishing techniques such as embossing and stiffening.

Common Applications in Textiles and Fashion

Cuprammonium rayon is valued for its fine, silk-like texture, making it ideal for luxury apparel such as blouses, scarves, and linings, while viscose rayon is commonly used in mass-produced clothing including dresses, shirts, and activewear due to its versatility and cost-effectiveness. Both fibers are favored in textile manufacturing for their breathability and ease of dyeing, but viscose rayon dominates in upholstery and home textiles like curtains and bed linens because of its durability. The fashion industry leverages cuprammonium rayon's smooth finish for high-end garments, whereas viscose rayon's adaptability supports a wide range of casual and formal fashion items.

Durability and Maintenance of Cuprammonium vs Viscose Fabrics

Cuprammonium rayon offers superior durability compared to viscose rayon due to its finer filaments and smoother fiber structure, resulting in less friction and wear over time. Maintenance of cuprammonium fabrics is easier as they resist shrinking and maintain shape better during washing, while viscose requires more delicate handling to avoid weakening and deformation. Both fabrics benefit from gentle care, but cuprammonium rayon's resilience makes it a practical choice for longer-lasting textile applications.

Market Availability and Cost Analysis

Cuprammonium rayon, produced using the cuprammonium process, has limited market availability due to its complex manufacturing and higher environmental impact, resulting in relatively higher production costs. Viscose rayon dominates the market with greater accessibility and cost efficiency, driven by established large-scale production and a variety of applications in textiles and apparel. Cost analysis reveals viscose rayon's affordability makes it preferable for mass-market products, while cuprammonium rayon is often reserved for niche applications requiring fine, high-quality fibers.

Cuprammonium Rayon vs Viscose Rayon Infographic

materialdif.com

materialdif.com