Platinum's exceptional hardness makes it a durable choice for fine jewelry, resisting scratches and maintaining its polished appearance over time. Despite this hardness, platinum also exhibits remarkable ductility, allowing it to be shaped into intricate designs without breaking or cracking. This unique combination of strength and flexibility ensures that platinum pieces are both long-lasting and artistically versatile.

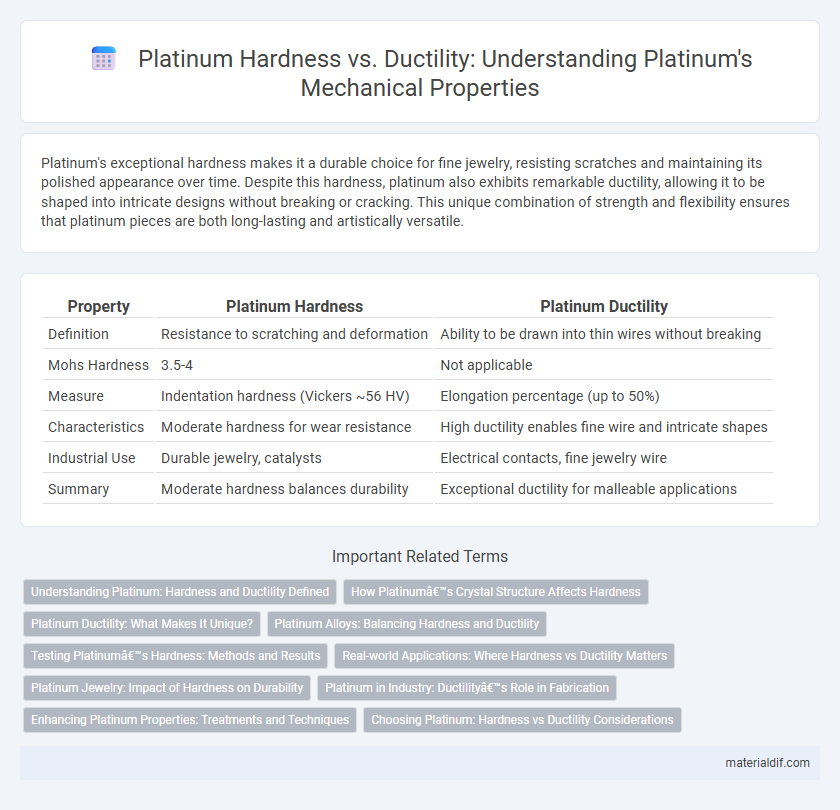

Table of Comparison

| Property | Platinum Hardness | Platinum Ductility |

|---|---|---|

| Definition | Resistance to scratching and deformation | Ability to be drawn into thin wires without breaking |

| Mohs Hardness | 3.5-4 | Not applicable |

| Measure | Indentation hardness (Vickers ~56 HV) | Elongation percentage (up to 50%) |

| Characteristics | Moderate hardness for wear resistance | High ductility enables fine wire and intricate shapes |

| Industrial Use | Durable jewelry, catalysts | Electrical contacts, fine jewelry wire |

| Summary | Moderate hardness balances durability | Exceptional ductility for malleable applications |

Understanding Platinum: Hardness and Ductility Defined

Platinum exhibits a hardness of approximately 4-4.5 on the Mohs scale, highlighting its resistance to scratching and wear, while its remarkable ductility allows it to be drawn into thin wires or hammered into extremely thin sheets without breaking. This unique combination of moderate hardness and exceptional ductility makes platinum ideal for use in fine jewelry and industrial applications requiring both durability and malleability. Understanding these properties underscores platinum's value as a versatile precious metal with both structural integrity and workable softness.

How Platinum’s Crystal Structure Affects Hardness

Platinum's face-centered cubic (FCC) crystal structure plays a crucial role in balancing its hardness and ductility by allowing atomic planes to slide easily, resulting in high ductility but moderate hardness. This atomic arrangement facilitates dislocation movement, which reduces hardness while enabling platinum to withstand deformation without fracturing. Consequently, platinum's FCC structure is responsible for its characteristic softness compared to other hard metals but provides exceptional malleability for various industrial and jewelry applications.

Platinum Ductility: What Makes It Unique?

Platinum exhibits remarkable ductility, allowing it to be drawn into extremely thin wires or hammered into delicate sheets without breaking, which sets it apart from many other metals known for hardness rather than flexibility. This unique ductility results from its face-centered cubic crystal structure, enabling atoms to slide past each other easily under stress. Compared to its hardness rating on the Mohs scale, which is relatively moderate at about 4-4.5, platinum's ductility makes it invaluable in fine jewelry and industrial applications where malleability and strength are essential.

Platinum Alloys: Balancing Hardness and Ductility

Platinum alloys are engineered to balance hardness and ductility, enhancing durability without sacrificing malleability; pure platinum has a Mohs hardness of 4-4.3, which is relatively soft, while alloying elements like cobalt and iridium significantly increase hardness to 5-6. The precise composition of platinum alloys determines their suitability for various applications, as higher hardness improves scratch resistance whereas maintained ductility ensures ease of fabrication and resistance to fracture.

Testing Platinum’s Hardness: Methods and Results

Testing platinum's hardness involves methods such as the Vickers, Knoop, and Mohs hardness tests, each providing precise measurements of its resistance to deformation. Platinum typically exhibits a Vickers hardness of around 56-59 HV, indicating moderate hardness compared to other metals, while its notable ductility allows for extensive shaping without fracturing. These hardness values confirm platinum's balance between durability and malleability, making it ideal for applications requiring both strength and flexibility.

Real-world Applications: Where Hardness vs Ductility Matters

Platinum's hardness and ductility significantly influence its use in various industries, with high hardness enhancing wear resistance in catalytic converters and dental instruments, while superior ductility ensures flexibility in fine jewelry and electrical contacts. In automotive catalytic converters, platinum's hardness prevents surface degradation under high temperatures, ensuring long-lasting performance, whereas in electronics, its ductility allows wires and connectors to bend without breaking. These real-world applications demand a balance between hardness and ductility to optimize durability and functionality in performance-critical environments.

Platinum Jewelry: Impact of Hardness on Durability

Platinum's hardness significantly influences its durability in jewelry, as higher hardness levels enhance scratch resistance, making pieces more resilient to daily wear. However, increased hardness reduces ductility, which limits the metal's ability to bend without breaking and affects the ease of crafting intricate designs. Balancing platinum hardness and ductility is essential for creating jewelry that remains strong yet retains sufficient flexibility to prevent cracking during use.

Platinum in Industry: Ductility’s Role in Fabrication

Platinum's ductility makes it a preferred material in various industrial applications, allowing it to be drawn into thin wires or hammered into intricate shapes without compromising structural integrity. Its hardness, while moderate compared to other metals, balances well with ductility to enable precise fabrication processes in electronics, automotive, and chemical industries. This combination of hardness and ductility ensures platinum maintains durability while adapting to complex manufacturing requirements, enhancing its value in high-performance equipment and catalytic converters.

Enhancing Platinum Properties: Treatments and Techniques

Platinum exhibits a unique balance of hardness and ductility, with a Mohs hardness of around 4 to 4.5, making it softer than many other metals but highly malleable and ductile, which allows for intricate designs. Enhancing platinum's hardness involves heat treatments such as annealing and alloying with metals like ruthenium or iridium, which improve wear resistance without significantly compromising its ductility. Advanced techniques like cold working and grain refinement also optimize platinum's mechanical properties, providing stronger yet still workable materials ideal for jewelry and industrial applications.

Choosing Platinum: Hardness vs Ductility Considerations

Platinum's hardness measures around 4-4.5 on the Mohs scale, making it durable for jewelry yet softer than metals like tungsten or titanium. Its high ductility allows extensive shaping and bending without cracking, ideal for intricate designs and fine details. Choosing between hardness and ductility depends on the application--hardness offers scratch resistance, while ductility ensures flexibility and ease of craftsmanship.

Platinum Hardness vs Platinum Ductility Infographic

materialdif.com

materialdif.com