Platinum catalysts offer superior durability and higher resistance to poisoning compared to palladium catalysts, making them ideal for demanding industrial applications. While palladium catalysts are generally more cost-effective and excel in hydrogenation reactions, platinum catalysts deliver enhanced performance in high-temperature environments and complex chemical processes. Choosing between platinum and palladium catalysts depends on balancing cost-efficiency with long-term reliability and specific reaction requirements.

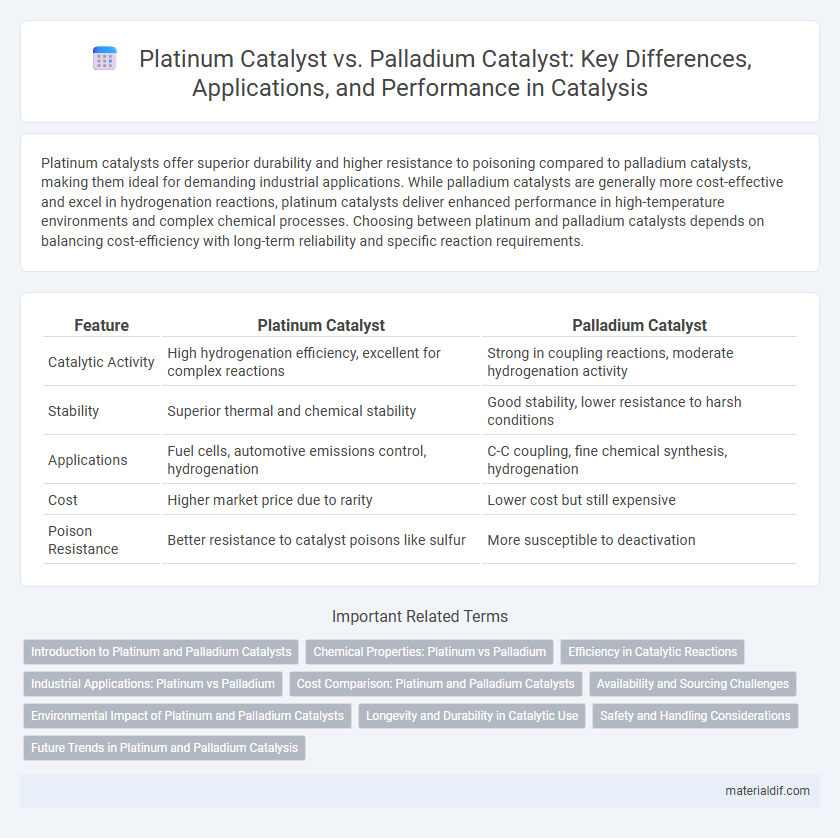

Table of Comparison

| Feature | Platinum Catalyst | Palladium Catalyst |

|---|---|---|

| Catalytic Activity | High hydrogenation efficiency, excellent for complex reactions | Strong in coupling reactions, moderate hydrogenation activity |

| Stability | Superior thermal and chemical stability | Good stability, lower resistance to harsh conditions |

| Applications | Fuel cells, automotive emissions control, hydrogenation | C-C coupling, fine chemical synthesis, hydrogenation |

| Cost | Higher market price due to rarity | Lower cost but still expensive |

| Poison Resistance | Better resistance to catalyst poisons like sulfur | More susceptible to deactivation |

Introduction to Platinum and Palladium Catalysts

Platinum catalysts exhibit exceptional catalytic activity and resistance to poisoning, making them ideal for hydrogenation and oxidation reactions in automotive and chemical industries. Palladium catalysts offer high selectivity and efficient performance in carbon-carbon coupling and hydrogenation processes, often preferred for cross-coupling reactions in pharmaceuticals. Both catalysts play crucial roles in accelerating chemical reactions, with platinum favored for its stability and palladium for its versatility in diverse catalytic applications.

Chemical Properties: Platinum vs Palladium

Platinum catalysts exhibit higher resistance to poisoning and greater thermal stability compared to palladium catalysts, making them ideal for high-temperature chemical reactions. Chemically, platinum has a higher atomic number (78) and electron density, which enhances its catalytic activity, especially in hydrogenation and oxidation processes. Palladium, atomic number 46, offers superior selectivity in coupling reactions but is less stable under harsh chemical environments than platinum.

Efficiency in Catalytic Reactions

Platinum catalysts exhibit higher efficiency in catalytic reactions due to their superior ability to adsorb and activate reactant molecules, resulting in faster reaction rates and greater selectivity compared to palladium catalysts. The strong metal-support interaction in platinum catalysts enhances their stability and resistance to poisoning, which is crucial for maintaining catalytic performance in industrial applications. While palladium catalysts are effective for hydrogenation and carbon-carbon coupling reactions, platinum remains the preferred choice for oxidation reactions and processes requiring prolonged catalyst durability.

Industrial Applications: Platinum vs Palladium

Platinum catalysts exhibit superior thermal stability and resistance to poisoning, making them ideal for high-temperature industrial processes such as catalytic reforming and emissions control in automotive exhaust systems. Palladium catalysts offer exceptional hydrogenation activity and are widely used in fuel cells, hydrogen purification, and organic synthesis, especially in cross-coupling reactions. Both metals serve critical roles in chemical manufacturing, with platinum preferred for durability under harsh conditions and palladium favored for selective hydrogenation and carbon-carbon bond formation.

Cost Comparison: Platinum and Palladium Catalysts

Platinum catalysts generally cost more than palladium catalysts due to platinum's higher market price and greater rarity. The cost difference impacts large-scale industrial applications, where palladium offers a more budget-friendly alternative without significantly compromising catalytic efficiency. Although platinum catalysts typically provide superior durability and resistance to poisoning, the economic advantage of palladium often drives its preference in cost-sensitive processes.

Availability and Sourcing Challenges

Platinum catalysts are rarer and face more significant availability challenges compared to palladium catalysts due to limited global reserves and concentrated mining regions primarily in South Africa and Russia. Palladium benefits from more diverse sources and increasing production, mainly as a by-product of nickel and platinum mining, reducing sourcing risks. Market volatility for platinum is higher, driven by geopolitical factors and supply chain complexities, whereas palladium's supply chain is comparatively more stable but still sensitive to automotive industry demand fluctuations.

Environmental Impact of Platinum and Palladium Catalysts

Platinum catalysts generally exhibit higher durability and lower metal leaching compared to palladium catalysts, reducing environmental contamination risks during industrial processes. Palladium catalysts may require more frequent replacement due to their susceptibility to poisoning and sintering, leading to increased resource consumption and waste generation. The superior recyclability of platinum catalysts contributes to a smaller ecological footprint, making them a more sustainable option for catalytic applications.

Longevity and Durability in Catalytic Use

Platinum catalysts exhibit superior longevity and durability compared to palladium catalysts due to their higher resistance to sintering and poisoning under harsh catalytic conditions. Platinum's stable electronic structure retains catalytic activity longer, making it ideal for industrial applications requiring extended operational life. In contrast, palladium catalysts tend to degrade faster, necessitating more frequent replacement and increasing overall maintenance costs.

Safety and Handling Considerations

Platinum catalysts exhibit lower toxicity and produce less hazardous waste compared to palladium catalysts, enhancing workplace safety during chemical processes. Platinum's higher thermal stability reduces the risk of decomposition and hazardous byproducts under high-temperature conditions. Proper handling protocols for platinum catalysts include using protective equipment to avoid skin contact and ensuring adequate ventilation to minimize inhalation of fine catalyst particles.

Future Trends in Platinum and Palladium Catalysis

Platinum catalysts exhibit superior thermal stability and resistance to poisoning compared to palladium catalysts, driving their growing adoption in automotive catalytic converters and fuel cells. Advances in nanostructuring and alloying techniques are enhancing the selectivity and efficiency of platinum-based catalysts, positioning them as key components in sustainable hydrogen production and carbon capture technologies. Market forecasts predict increased investment in platinum catalysis due to stricter emission regulations and the rising demand for clean energy solutions, while palladium faces supply challenges that may limit its catalytic applications.

Platinum Catalyst vs Palladium Catalyst Infographic

materialdif.com

materialdif.com