Platinum soldering offers superior strength and corrosion resistance compared to gold soldering, making it ideal for high-performance applications and fine jewelry craftsmanship. While gold soldering provides excellent malleability and color matching for gold alloys, platinum soldering requires higher temperatures and special flux, resulting in more durable and heat-resistant joins. Choosing between platinum and gold soldering depends on the metal type, desired strength, and the specific requirements of the jewelry piece.

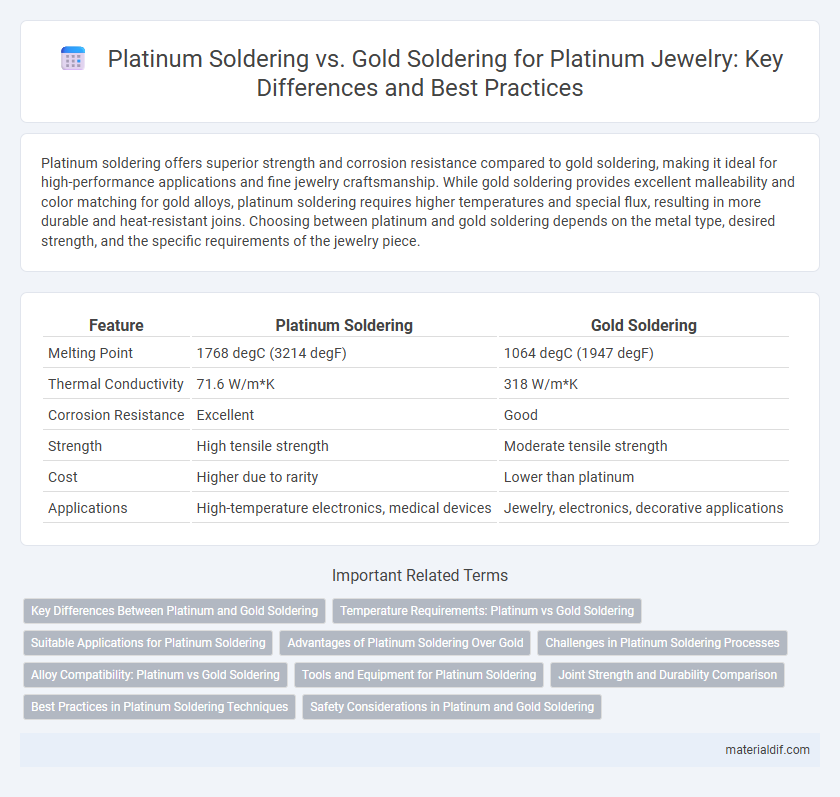

Table of Comparison

| Feature | Platinum Soldering | Gold Soldering |

|---|---|---|

| Melting Point | 1768 degC (3214 degF) | 1064 degC (1947 degF) |

| Thermal Conductivity | 71.6 W/m*K | 318 W/m*K |

| Corrosion Resistance | Excellent | Good |

| Strength | High tensile strength | Moderate tensile strength |

| Cost | Higher due to rarity | Lower than platinum |

| Applications | High-temperature electronics, medical devices | Jewelry, electronics, decorative applications |

Key Differences Between Platinum and Gold Soldering

Platinum soldering requires higher temperatures ranging from 1,200degC to 1,400degC compared to gold soldering, which typically occurs between 900degC and 1,100degC, impacting the choice of flux and solder alloys. Platinum's superior corrosion resistance and durability make it ideal for jewelry and industrial applications where longevity is crucial, while gold soldering offers greater malleability and a broader color range for crafting intricate designs. The melting points and thermal conductivity differences influence the precision and strength of the joint, with platinum joints exhibiting higher tensile strength but demanding more specialized equipment and skill.

Temperature Requirements: Platinum vs Gold Soldering

Platinum soldering requires significantly higher temperatures, typically ranging from 1,200degC to 1,400degC, compared to gold soldering, which generally occurs between 900degC and 1,100degC. The elevated melting point of platinum alloys demands specialized torches and fluxes to achieve proper joint formation without compromising the metal's integrity. Gold soldering benefits from lower thermal stress, allowing for faster work cycles and reduced risk of metal distortion during the repair or fabrication process.

Suitable Applications for Platinum Soldering

Platinum soldering is ideal for high-temperature applications in industries such as jewelry making, electronics, and medical devices due to its excellent corrosion resistance and thermal stability. It is particularly suitable for joining platinum and other noble metals where strength and durability are critical. Unlike gold soldering, which is often preferred for decorative purposes, platinum soldering excels in environments requiring robust mechanical properties and resistance to oxidation.

Advantages of Platinum Soldering Over Gold

Platinum soldering offers superior corrosion resistance and higher melting points compared to gold soldering, making it ideal for high-temperature applications and harsh environments. Its inertness ensures minimal contamination and oxidation during the soldering process, resulting in stronger and more durable joints. Cost-efficiency and enhanced mechanical strength further position platinum soldering as a preferred choice in precision industries like electronics and jewelry manufacturing.

Challenges in Platinum Soldering Processes

Platinum soldering presents significant challenges due to its high melting point of approximately 1,768degC, requiring specialized fluxes and precise temperature control to avoid overheating and metal distortion. The metal's chemical inertness complicates flux adherence and joint formation, often leading to weak or incomplete bonds compared to gold soldering, which involves lower melting points and easier flux activation. Managing thermal expansion differences and preventing oxidation in platinum soldering demand advanced equipment and expert techniques, making it a more complex process than gold soldering in jewelry and industrial applications.

Alloy Compatibility: Platinum vs Gold Soldering

Platinum soldering requires alloys with high melting points and excellent oxidation resistance to maintain joint integrity, often utilizing platinum-based or high-temperature silver alloys. Gold soldering benefits from alloys with lower melting points and greater malleability, including gold-silver or gold-copper combinations, enabling smoother flow and strong bonds on gold substrates. Compatibility depends on matching alloy compositions and melting temperatures to avoid weak joints or substrate damage during soldering processes.

Tools and Equipment for Platinum Soldering

Platinum soldering requires specialized tools such as high-temperature torches capable of reaching temperatures above 1,700degC, platinum solder alloys, and protective equipment to handle the intense heat safely. Unlike gold soldering, which uses lower melting point solders and standard jeweler's torches, platinum soldering demands precise flame control and fluxes designed to prevent oxidation at extreme temperatures. Essential tools include a gas-rich torch tip, an accurate temperature gauge, and firebrick or soldering block to withstand the heightened thermal stress unique to platinum work.

Joint Strength and Durability Comparison

Platinum soldering typically provides superior joint strength and enhanced durability compared to gold soldering due to its higher melting point and resistance to corrosion. Platinum solder joints maintain integrity under extreme thermal and mechanical stress, making them ideal for applications requiring long-term reliability. Gold solder joints, while easier to work with, generally exhibit lower tensile strength and are more prone to degradation in harsh environments.

Best Practices in Platinum Soldering Techniques

Platinum soldering requires precise temperature control and the use of high-purity platinum solder alloys to ensure strong, clean joints resistant to corrosion and high heat. Best practices include thorough cleaning of the platinum surfaces, using fluxes specifically designed for platinum to promote wetting, and applying heat evenly with a controlled torch flame to avoid overheating and platinum's potential grain growth. Unlike gold soldering, platinum demands slower, more deliberate heating cycles and specialized equipment to achieve optimal durability and finish.

Safety Considerations in Platinum and Gold Soldering

Platinum soldering requires careful attention to ventilation due to its high melting point and the release of potentially harmful fumes, making proper respiratory protection essential. Gold soldering typically produces less toxic fumes but still demands adequate ventilation and protective gear to prevent exposure to metal fumes and hot materials. Both processes benefit from the use of gloves, eye protection, and temperature-controlled equipment to minimize risks associated with burns and inhalation of hazardous substances.

Platinum Soldering vs Gold Soldering Infographic

materialdif.com

materialdif.com