Platinum casting involves melting platinum and pouring it into molds to create complex shapes with precise details, ideal for mass production and intricate designs. Platinum hand-forging requires skilled artisans to manually shape and hammer the metal, resulting in unique pieces with exceptional strength and craftsmanship. While casting offers efficiency and consistency, hand-forging delivers superior durability and a personalized touch.

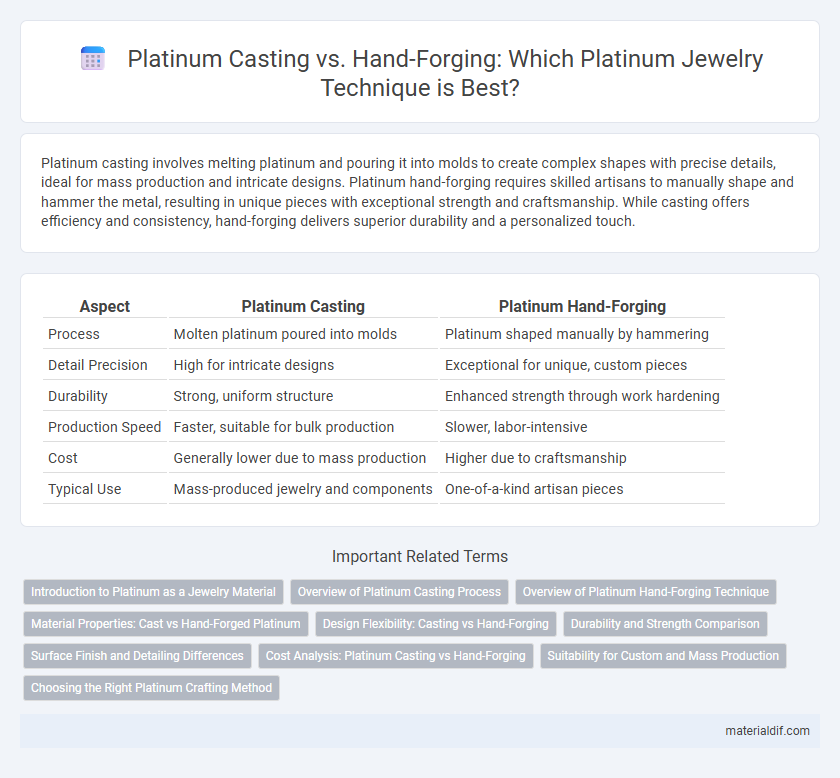

Table of Comparison

| Aspect | Platinum Casting | Platinum Hand-Forging |

|---|---|---|

| Process | Molten platinum poured into molds | Platinum shaped manually by hammering |

| Detail Precision | High for intricate designs | Exceptional for unique, custom pieces |

| Durability | Strong, uniform structure | Enhanced strength through work hardening |

| Production Speed | Faster, suitable for bulk production | Slower, labor-intensive |

| Cost | Generally lower due to mass production | Higher due to craftsmanship |

| Typical Use | Mass-produced jewelry and components | One-of-a-kind artisan pieces |

Introduction to Platinum as a Jewelry Material

Platinum casting involves melting the metal and pouring it into molds to create intricate jewelry designs with precise detail and uniformity. Platinum hand-forging requires skilled artisans to shape and hammer the metal manually, resulting in unique, custom pieces with enhanced strength and density. Both techniques leverage platinum's natural durability, hypoallergenic properties, and brilliant white luster, making it a premium choice for fine jewelry.

Overview of Platinum Casting Process

The platinum casting process involves melting platinum at temperatures above 1,700degC and pouring it into detailed molds to create complex shapes with high precision. This method allows for efficient mass production of intricate jewelry designs while maintaining the metal's durability and natural luster. Compared to hand-forging, casting offers consistent results and the ability to replicate elaborate textures and patterns that are difficult to achieve manually.

Overview of Platinum Hand-Forging Technique

Platinum hand-forging involves shaping platinum by manually hammering and manipulating the metal, enhancing its structural integrity and creating unique textures. This technique allows for precise control over the thickness and design details, resulting in durable, custom pieces with superior grain alignment compared to casting. Unlike platinum casting, which melts and molds the metal, hand-forging preserves the metal's inherent strength and reduces porosity, making it ideal for high-quality jewelry and artisanal applications.

Material Properties: Cast vs Hand-Forged Platinum

Platinum casting allows for intricate designs by melting and pouring the metal into molds, resulting in a uniform microstructure with consistent density but slightly lower tensile strength compared to hand-forged platinum. Hand-forged platinum involves repeatedly hammering the metal, enhancing its grain structure and increasing hardness, toughness, and tensile strength due to work hardening. The superior mechanical properties of hand-forged platinum make it ideal for high-stress applications, while cast platinum offers more design flexibility and complex shapes.

Design Flexibility: Casting vs Hand-Forging

Platinum casting offers superior design flexibility, enabling intricate and complex shapes that are difficult to achieve with hand-forging techniques. This process allows for the precise replication of detailed patterns and delicate structures, making it ideal for customized jewelry pieces. Hand-forging, while providing exceptional strength and a unique artisanal finish, is limited in the complexity of designs compared to the versatility of casting.

Durability and Strength Comparison

Platinum casting involves melting and pouring the metal into molds, resulting in uniform density but potential microscopic porosity that may affect long-term strength. Hand-forging compresses and shapes platinum by hammering, enhancing its grain structure and increasing durability through work hardening. Compared to casting, hand-forged platinum typically exhibits superior strength and resistance to wear, making it more suitable for jewelry subjected to daily use.

Surface Finish and Detailing Differences

Platinum casting produces a smooth and consistent surface finish ideal for intricate designs, but may exhibit minor porosity or imperfections requiring polishing. Platinum hand-forging delivers superior detailing with sharper lines and enhanced texture due to manual shaping, resulting in a more unique and tactile finish. The choice depends on the desired balance between precision and artisanal character in the final piece.

Cost Analysis: Platinum Casting vs Hand-Forging

Platinum casting typically incurs lower initial labor costs compared to hand-forging due to streamlined mold-making and repetitive production processes. Hand-forging platinum demands significant skilled craftsmanship and time, driving up the overall expense despite the superior strength and intricate detailing it offers. Cost analysis reveals casting is more economical for mass production, while hand-forging justifies its higher price through unique customization and durability.

Suitability for Custom and Mass Production

Platinum casting offers excellent suitability for mass production due to its ability to create intricate designs with consistent quality and minimal manual labor. Platinum hand-forging provides superior customization, allowing artisans to craft unique, detailed pieces tailored to individual specifications, ideal for bespoke jewelry. While casting streamlines volume manufacturing, hand-forging excels in personalized craftsmanship and structural durability in platinum pieces.

Choosing the Right Platinum Crafting Method

Platinum casting offers precision and efficiency, allowing complex designs to be reproduced consistently, making it ideal for detailed jewelry pieces. Platinum hand-forging emphasizes artisanal skill and durability, producing stronger, more resilient pieces through manual shaping and hammering. Choosing the right platinum crafting method depends on the desired design complexity, durability requirements, and production volume.

Platinum Casting vs Platinum Hand-Forging Infographic

materialdif.com

materialdif.com