Platinum jewelry is prized for its brilliant luster, durability, and hypoallergenic properties, making it a popular choice for wedding bands and luxury accessories. In contrast, platinum's industrial applications leverage its high resistance to corrosion and excellent catalytic properties, especially in automotive catalytic converters and chemical processing equipment. While both uses benefit from platinum's unique physical and chemical characteristics, jewelry emphasizes aesthetic appeal, whereas industrial use prioritizes functionality and performance.

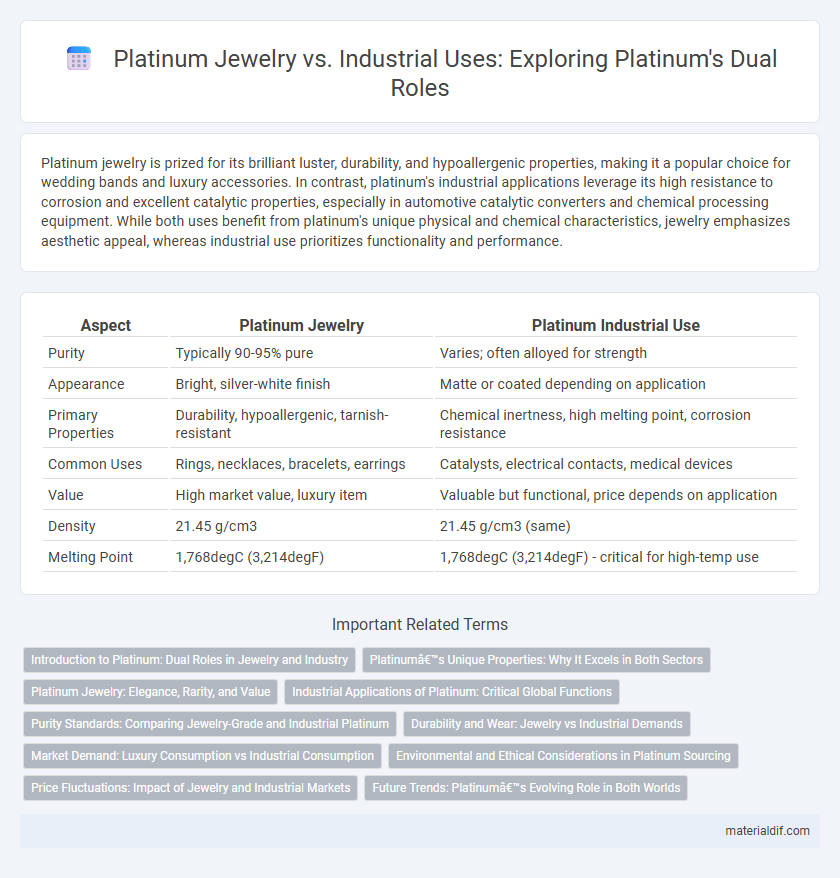

Table of Comparison

| Aspect | Platinum Jewelry | Platinum Industrial Use |

|---|---|---|

| Purity | Typically 90-95% pure | Varies; often alloyed for strength |

| Appearance | Bright, silver-white finish | Matte or coated depending on application |

| Primary Properties | Durability, hypoallergenic, tarnish-resistant | Chemical inertness, high melting point, corrosion resistance |

| Common Uses | Rings, necklaces, bracelets, earrings | Catalysts, electrical contacts, medical devices |

| Value | High market value, luxury item | Valuable but functional, price depends on application |

| Density | 21.45 g/cm3 | 21.45 g/cm3 (same) |

| Melting Point | 1,768degC (3,214degF) | 1,768degC (3,214degF) - critical for high-temp use |

Introduction to Platinum: Dual Roles in Jewelry and Industry

Platinum serves a dual role as a precious metal used in high-end jewelry and a critical material in various industrial applications. Its exceptional durability, corrosion resistance, and catalytic properties make it invaluable for crafting elegant, enduring jewelry pieces as well as for use in catalytic converters, medical devices, and electronics. The metal's rarity and unique physical qualities position it at the intersection of luxury aesthetics and advanced technological innovation.

Platinum’s Unique Properties: Why It Excels in Both Sectors

Platinum's exceptional durability, resistance to tarnish, and hypoallergenic nature make it an ideal choice for fine jewelry, ensuring lasting beauty and comfort for wearers. In industrial applications, its high melting point, excellent catalytic properties, and corrosion resistance enable reliable performance in harsh environments such as catalytic converters, electronics, and chemical processing. These unique characteristics allow platinum to seamlessly excel in both aesthetic and functional sectors, balancing elegance and technical efficiency.

Platinum Jewelry: Elegance, Rarity, and Value

Platinum jewelry is prized for its unmatched elegance, rarity, and enduring value, often symbolizing prestige and luxury in fine accessories. Its naturally white luster and hypoallergenic properties make it a preferred metal for high-end rings, necklaces, and bracelets, enhancing both aesthetics and durability. Unlike industrial applications, where platinum's catalytic and corrosion-resistant qualities are key, its use in jewelry centers on craftsmanship, timeless appeal, and considerable market demand.

Industrial Applications of Platinum: Critical Global Functions

Platinum's exceptional corrosion resistance, high melting point, and superior catalytic properties make it indispensable in industrial applications such as automotive catalytic converters, which significantly reduce harmful emissions worldwide. In electronics, platinum is used in hard disk drives and thermocouples for precise temperature measurements, ensuring device reliability. Additionally, the chemical industry relies on platinum catalysts for the production of fertilizers, silicone, and pharmaceuticals, highlighting its critical role in global manufacturing and environmental sustainability.

Purity Standards: Comparing Jewelry-Grade and Industrial Platinum

Platinum jewelry typically uses alloys with a purity of 90-95%, combining durability with a lustrous finish ideal for fine accessories. Industrial platinum demands higher purity levels, often exceeding 99.9%, to ensure optimal catalytic properties and corrosion resistance in applications like automotive catalysts and electronics. The variance in purity standards reflects the distinct requirements for aesthetic appeal in jewelry versus functional performance in industrial uses.

Durability and Wear: Jewelry vs Industrial Demands

Platinum jewelry demands exceptional durability and resistance to tarnish, ensuring longevity and maintaining its lustrous appearance despite daily wear. In industrial applications, platinum's durability is critical under extreme conditions such as high temperatures and corrosive environments, where it sustains performance without degradation. The metal's unique combination of hardness and malleability allows it to fulfill both aesthetic wearability in jewelry and rigorous functional requirements in industrial uses.

Market Demand: Luxury Consumption vs Industrial Consumption

Platinum jewelry commands high market demand driven by luxury consumption, with global sales influenced by emerging wealth in Asia and sustained interest in fine craftsmanship. Industrial use of platinum, particularly in automotive catalytic converters and electronics, exhibits steady demand tied to manufacturing and environmental regulations promoting emission reductions. Price volatility often reflects shifts in luxury spending patterns alongside fluctuations in industrial production and technological advancements.

Environmental and Ethical Considerations in Platinum Sourcing

Platinum used in jewelry often undergoes stringent ethical sourcing and recycling protocols to minimize environmental impact and support responsible mining practices. Industrial applications, including catalytic converters and electronics, rely on platinum sourced from large-scale mining operations where environmental regulations vary, leading to challenges in ensuring sustainable practices. Both sectors face increasing pressure to adopt transparent supply chains and reduce carbon footprints to address ethical and ecological concerns in platinum extraction and use.

Price Fluctuations: Impact of Jewelry and Industrial Markets

Platinum prices exhibit significant fluctuations driven by contrasting demands in jewelry and industrial sectors. Jewelry markets, influenced by luxury trends and consumer preferences, can increase platinum prices during high demand periods, whereas industrial use, particularly in automotive catalytic converters and electronics, introduces volatility linked to economic cycles and technological advancements. These dual demands create a dynamic price environment where supply constraints and market shifts in either sector directly impact platinum's overall valuation.

Future Trends: Platinum’s Evolving Role in Both Worlds

Platinum's future in jewelry is driven by rising consumer demand for sustainable, hypoallergenic luxury pieces and innovative designs utilizing its durability and lustrous appeal. Industrial applications continue expanding, particularly in automotive catalytic converters and hydrogen fuel cells, where platinum's unparalleled catalytic properties enhance efficiency and reduce emissions. Advances in nanotechnology and recycling methods are poised to optimize platinum use across both sectors, reinforcing its dual role as a precious metal in jewelry and a critical material in clean energy and environmental technologies.

Platinum Jewelry vs Platinum Industrial Use Infographic

materialdif.com

materialdif.com