Platinum electroplating creates a durable, luxurious finish that resists tarnishing and corrosion better than rhodium plating. Unlike rhodium, which wears off over time and requires frequent reapplication, platinum plating maintains its luster and strength for a longer period. This makes platinum electroplating ideal for high-quality jewelry seeking long-lasting elegance and protection.

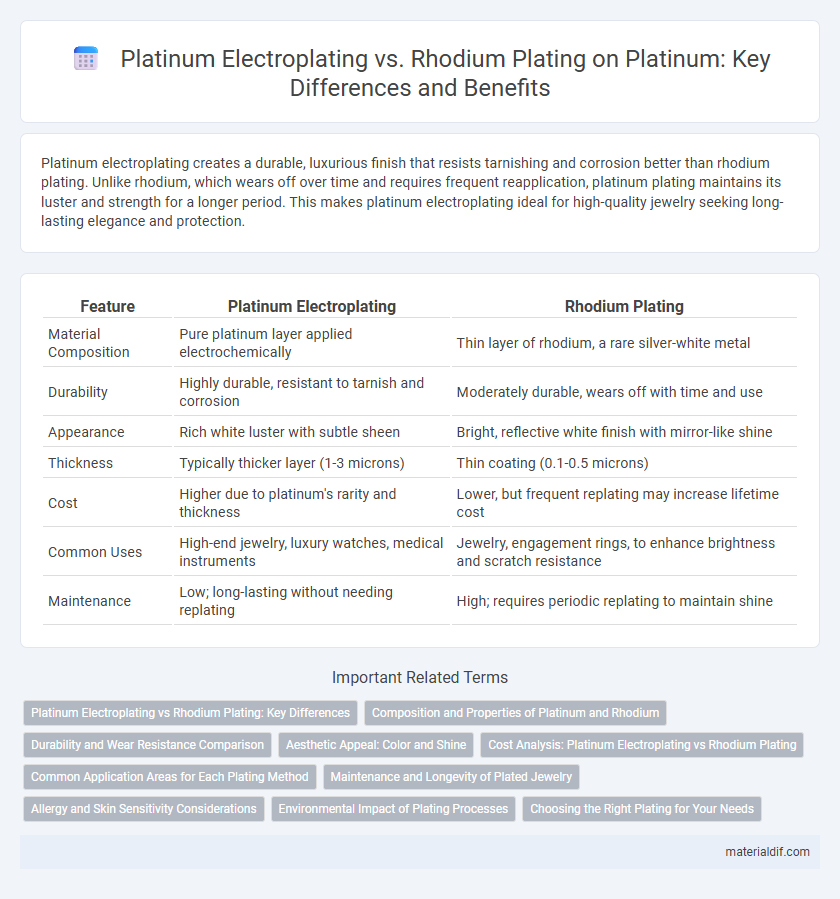

Table of Comparison

| Feature | Platinum Electroplating | Rhodium Plating |

|---|---|---|

| Material Composition | Pure platinum layer applied electrochemically | Thin layer of rhodium, a rare silver-white metal |

| Durability | Highly durable, resistant to tarnish and corrosion | Moderately durable, wears off with time and use |

| Appearance | Rich white luster with subtle sheen | Bright, reflective white finish with mirror-like shine |

| Thickness | Typically thicker layer (1-3 microns) | Thin coating (0.1-0.5 microns) |

| Cost | Higher due to platinum's rarity and thickness | Lower, but frequent replating may increase lifetime cost |

| Common Uses | High-end jewelry, luxury watches, medical instruments | Jewelry, engagement rings, to enhance brightness and scratch resistance |

| Maintenance | Low; long-lasting without needing replating | High; requires periodic replating to maintain shine |

Platinum Electroplating vs Rhodium Plating: Key Differences

Platinum electroplating provides a durable, highly corrosion-resistant coating with a natural white luster that maintains its shine over time, making it ideal for jewelry and industrial applications where longevity is critical. Rhodium plating offers a brighter, reflective finish but is softer and may wear off faster, requiring more frequent re-plating to preserve appearance. Differences between the two include platinum's superior hardness and tarnish resistance versus rhodium's higher reflectivity and cost-effectiveness for achieving a mirror-like finish.

Composition and Properties of Platinum and Rhodium

Platinum electroplating involves depositing a layer of pure platinum, a dense, malleable metal known for its excellent corrosion resistance and high melting point of 1,768degC, which ensures durability and a lasting, lustrous finish. Rhodium plating applies a thin layer of rhodium, a member of the platinum group with a higher reflectivity and exceptional hardness, offering superior scratch resistance and a bright, white metallic sheen. Both metals provide excellent protection against tarnish, but platinum's natural density and resistance make it ideal for luxury jewelry, while rhodium's hardness is preferred for enhancing surface durability and brightness.

Durability and Wear Resistance Comparison

Platinum electroplating offers superior durability and wear resistance due to its dense, hard surface that withstands scratches and tarnish over time. Rhodium plating provides a bright, reflective finish but tends to wear off faster, especially on frequently handled jewelry, requiring more frequent re-plating. The inherent strength and corrosion resistance of platinum make it a longer-lasting protective layer compared to rhodium's aesthetic but less robust coating.

Aesthetic Appeal: Color and Shine

Platinum electroplating offers a distinctive silvery-white sheen with a subtle grayish tone that enhances jewelry's elegance and maintains its luster over time. Rhodium plating delivers a bright, mirror-like finish with a more reflective white surface that intensifies the brilliance and contrast of gemstones. The choice between platinum and rhodium plating largely depends on the desired aesthetic, with platinum providing a softer, vintage appeal and rhodium creating a striking, contemporary shine.

Cost Analysis: Platinum Electroplating vs Rhodium Plating

Platinum electroplating typically incurs higher material costs due to platinum's rarity and premium market price, averaging between $30 to $50 per gram compared to rhodium's $400 to $600 per gram but used in thinner layers. Rhodium plating, while more expensive per gram, generally requires less material thickness, resulting in lower overall plating costs in jewelry applications. Labor and process complexity also influence expenses, with platinum electroplating demanding longer plating times and more rigorous handling protocols, increasing operational costs relative to rhodium plating.

Common Application Areas for Each Plating Method

Platinum electroplating is widely used in automotive parts, electrical contacts, and medical devices due to its excellent corrosion resistance and conductivity. Rhodium plating is popular in jewelry, especially white gold and silver pieces, for its high reflectivity and scratch resistance. Both plating methods find common applications in enhancing the durability and aesthetic appeal of fine jewelry and industrial components.

Maintenance and Longevity of Plated Jewelry

Platinum electroplating offers exceptional durability and resistance to tarnish, requiring minimal maintenance compared to other coatings. Rhodium plating provides a brilliant white finish but tends to wear off faster, especially on frequently worn jewelry, necessitating regular re-plating every 6 to 12 months. For long-lasting shine and reduced upkeep, platinum electroplating is often preferred due to its superior hardness and corrosion resistance.

Allergy and Skin Sensitivity Considerations

Platinum electroplating offers superior hypoallergenic properties, making it ideal for individuals with sensitive skin or metal allergies due to its inert nature and resistance to tarnish. Rhodium plating, while also hypoallergenic, can sometimes cause skin irritation or allergic reactions because it tends to wear off faster, exposing underlying alloys that may contain nickel or other allergens. Choosing platinum electroplating reduces the risk of skin sensitivity and allergic responses, ensuring longer-lasting protection and comfort for sensitive wearers.

Environmental Impact of Plating Processes

Platinum electroplating uses fewer harmful chemicals and generates less toxic waste compared to rhodium plating, making it a more environmentally friendly option. Rhodium plating often involves the use of hazardous substances such as hexavalent chromium, which poses significant environmental and health risks. The lower environmental footprint of platinum electroplating supports sustainable practices in the jewelry and automotive industries.

Choosing the Right Plating for Your Needs

Platinum electroplating offers superior durability and a natural silver-white finish ideal for high-wear jewelry and industrial applications, providing excellent corrosion resistance and hypoallergenic properties. Rhodium plating delivers a brilliant, mirror-like shine that enhances the brilliance of white gold and silver but tends to wear off faster, requiring periodic re-plating to maintain appearance. Selecting between platinum electroplating and rhodium plating depends on desired longevity, visual aesthetics, and budget considerations, with platinum favored for lasting protection and rhodium chosen for enhancing brightness and luster.

Platinum Electroplating vs Rhodium Plating Infographic

materialdif.com

materialdif.com