Platinum Group Metals (PGMs) include platinum, palladium, rhodium, ruthenium, iridium, and osmium, known for their exceptional catalytic properties and resistance to corrosion. Noble metals, a broader category, comprise PGMs along with gold and silver, valued for their rarity, luster, and chemical inertness. While all PGMs are noble metals due to their high resistance to oxidation and corrosion, not all noble metals belong to the platinum group.

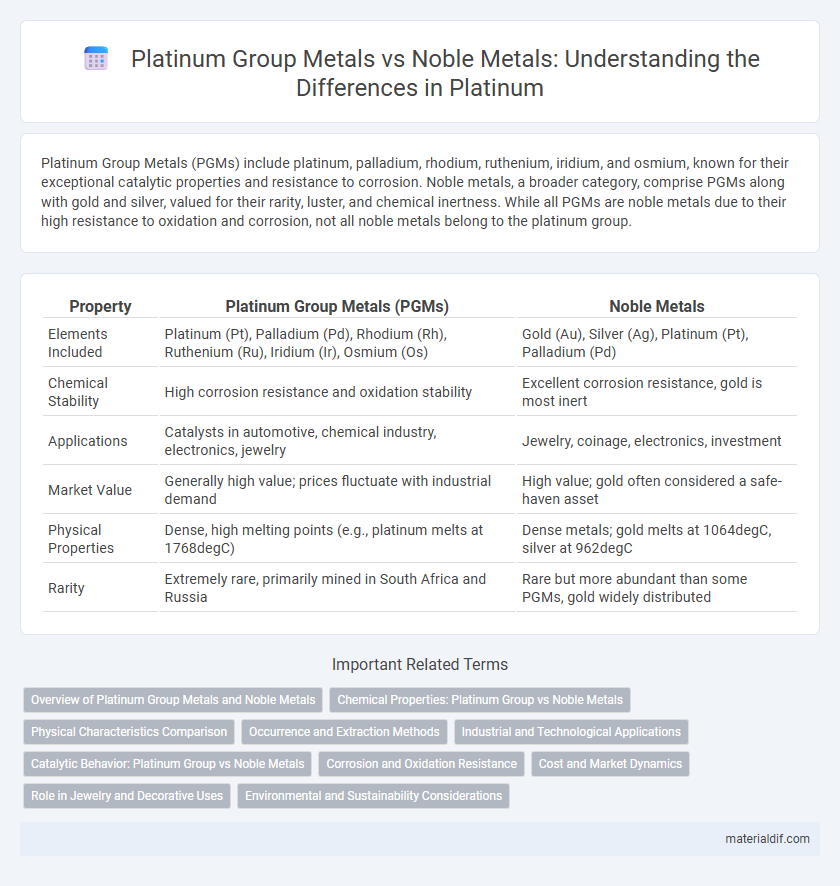

Table of Comparison

| Property | Platinum Group Metals (PGMs) | Noble Metals |

|---|---|---|

| Elements Included | Platinum (Pt), Palladium (Pd), Rhodium (Rh), Ruthenium (Ru), Iridium (Ir), Osmium (Os) | Gold (Au), Silver (Ag), Platinum (Pt), Palladium (Pd) |

| Chemical Stability | High corrosion resistance and oxidation stability | Excellent corrosion resistance, gold is most inert |

| Applications | Catalysts in automotive, chemical industry, electronics, jewelry | Jewelry, coinage, electronics, investment |

| Market Value | Generally high value; prices fluctuate with industrial demand | High value; gold often considered a safe-haven asset |

| Physical Properties | Dense, high melting points (e.g., platinum melts at 1768degC) | Dense metals; gold melts at 1064degC, silver at 962degC |

| Rarity | Extremely rare, primarily mined in South Africa and Russia | Rare but more abundant than some PGMs, gold widely distributed |

Overview of Platinum Group Metals and Noble Metals

Platinum Group Metals (PGMs) include platinum, palladium, rhodium, ruthenium, iridium, and osmium, known for their exceptional catalytic properties and high resistance to corrosion. Noble metals such as gold, silver, and platinum exhibit superior chemical stability and resistance to oxidation, making them valuable in jewelry, electronics, and investment. PGMs are critical in industrial applications, especially in automotive catalytic converters, whereas noble metals are prized for both industrial use and financial assets.

Chemical Properties: Platinum Group vs Noble Metals

Platinum Group Metals (PGMs) such as platinum, palladium, rhodium, ruthenium, iridium, and osmium exhibit exceptional catalytic properties, high resistance to oxidation, and excellent corrosion resistance, distinguishing them chemically from traditional Noble Metals like gold and silver. PGMs are characterized by their robust electron configurations, enabling efficient electron transfer in catalytic processes and stable behavior in harsh chemical environments. In contrast, Noble Metals primarily resist tarnishing and oxidation due to their filled d-orbitals but show less catalytic versatility compared to PGMs.

Physical Characteristics Comparison

Platinum Group Metals (PGMs) including platinum, palladium, rhodium, ruthenium, iridium, and osmium exhibit high melting points ranging from 1,550degC to 2,460degC, significantly exceeding those of traditional noble metals like gold and silver. PGMs possess exceptional hardness and corrosion resistance, with densities between 12 and 22.6 g/cm3, surpassing common noble metals such as gold (19.3 g/cm3) and silver (10.49 g/cm3). These physical properties make PGMs crucial in industrial applications requiring durability and stability under extreme conditions, distinguishing them from softer and more reactive noble metals.

Occurrence and Extraction Methods

Platinum Group Metals (PGMs), including platinum, palladium, rhodium, ruthenium, iridium, and osmium, primarily occur in layered mafic to ultramafic igneous complexes and are often found alongside nickel and copper ores. Noble metals, such as gold and silver, typically occur in hydrothermal veins and alluvial deposits with higher atomic resistance to corrosion and oxidation. Extraction methods for PGMs commonly involve complex flotation, smelting, and refining processes to separate them from sulfide ores, whereas noble metals are often recovered through simpler cyanidation or amalgamation techniques.

Industrial and Technological Applications

Platinum Group Metals (PGMs), including platinum, palladium, rhodium, ruthenium, iridium, and osmium, are essential in catalytic converters, fuel cells, and hydrogen production due to their exceptional catalytic properties and high resistance to corrosion and wear. Noble metals like gold, silver, and platinum exhibit excellent conductivity and chemical stability, making them invaluable in electronics, dental alloys, and chemical apparatus where durability and reliability are paramount. Industrial applications leverage PGMs for emission control and renewable energy technologies, while noble metals often dominate sectors requiring superior electrical conductivity and inertness.

Catalytic Behavior: Platinum Group vs Noble Metals

Platinum group metals (PGMs) such as platinum, palladium, and rhodium exhibit superior catalytic behavior compared to traditional noble metals like gold and silver, due to their unique electronic structures and ability to adsorb and activate reactant molecules efficiently. PGMs excel in oxidation, hydrogenation, and reforming reactions, making them essential in automotive catalytic converters and industrial processes. In contrast, noble metals primarily offer corrosion resistance but lack the catalytic versatility and activity demonstrated by platinum group metals in chemical transformations.

Corrosion and Oxidation Resistance

Platinum Group Metals (PGMs), including platinum, palladium, rhodium, ruthenium, iridium, and osmium, exhibit exceptional corrosion and oxidation resistance, outperforming many noble metals like gold and silver due to their stable d-electron configurations and high melting points. These properties ensure that PGMs maintain their structural integrity and catalytic activity in harsh chemical environments and high temperatures, making them essential in automotive catalytic converters, chemical processing, and aerospace industries. Unlike some noble metals that can oxidize or tarnish under certain conditions, PGMs form passive oxide layers that protect against further degradation, enhancing durability and lifespan in industrial applications.

Cost and Market Dynamics

Platinum Group Metals (PGMs) including platinum, palladium, rhodium, ruthenium, iridium, and osmium typically have higher market volatility and cost due to their rarity and industrial demand in catalytic converters and hydrogen fuel cells. Noble metals such as gold and silver are more stable in price, with gold especially valued for its investment demand and historical role as a store of value. Market dynamics for PGMs are influenced heavily by automotive industry regulations and technological innovations, whereas noble metals respond more to macroeconomic trends and monetary policies.

Role in Jewelry and Decorative Uses

Platinum group metals, including platinum, palladium, and rhodium, are highly valued in jewelry for their durability, resistance to tarnish, and natural white luster, making them ideal for everyday wear and intricate designs. Noble metals like gold and silver also feature prominently in decorative uses due to their malleability and warm tones, but they often require plating or alloying to enhance hardness and longevity. The superior hardness and hypoallergenic properties of platinum group metals provide significant advantages in high-end jewelry, ensuring both elegance and enduring performance.

Environmental and Sustainability Considerations

Platinum Group Metals (PGMs), including platinum, palladium, and rhodium, exhibit superior catalytic properties vital for reducing automotive emissions and enabling clean energy technologies, positioning them as essential in sustainable industrial applications. Unlike some traditional noble metals such as gold and silver, PGMs often benefit from more established recycling processes, which mitigate environmental impact by reducing mining demands and preserving natural resources. Sustainable sourcing of PGMs remains critical due to energy-intensive extraction methods and the ecological footprint of mining operations, prompting advancements in responsible mining practices and circular economy initiatives.

Platinum Group Metals vs Noble Metals Infographic

materialdif.com

materialdif.com