Platinum Black offers a sleek, durable finish ideal for high-end pet accessories, combining luxury with robust protection. Platinum Sponge provides a soft, cushioned texture designed to enhance comfort and absorb impact, perfect for pet bedding and toys. Choosing between Platinum Black and Platinum Sponge depends on whether the priority is aesthetic elegance or functional softness in pet products.

Table of Comparison

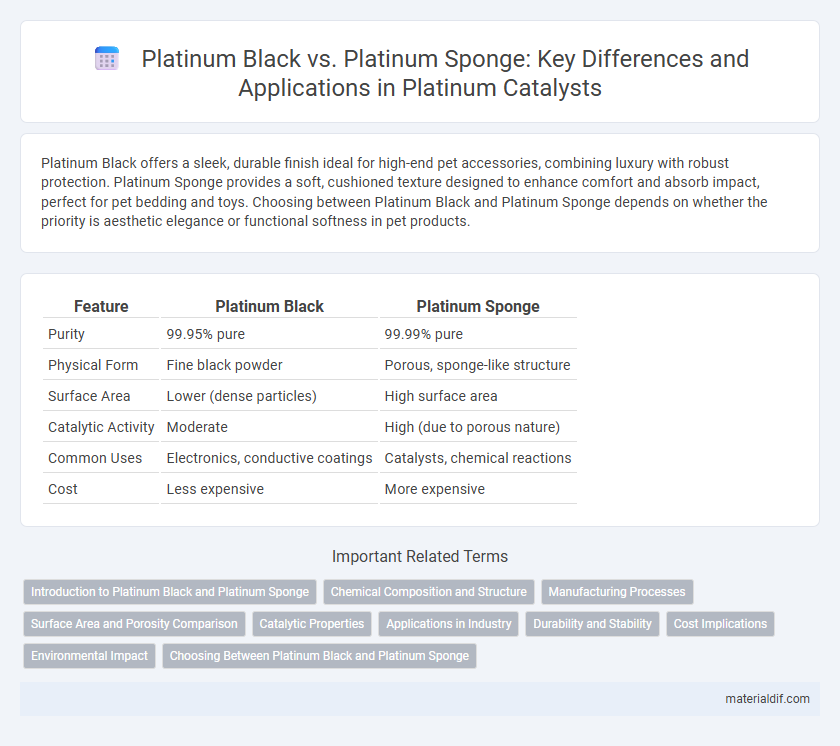

| Feature | Platinum Black | Platinum Sponge |

|---|---|---|

| Purity | 99.95% pure | 99.99% pure |

| Physical Form | Fine black powder | Porous, sponge-like structure |

| Surface Area | Lower (dense particles) | High surface area |

| Catalytic Activity | Moderate | High (due to porous nature) |

| Common Uses | Electronics, conductive coatings | Catalysts, chemical reactions |

| Cost | Less expensive | More expensive |

Introduction to Platinum Black and Platinum Sponge

Platinum Black consists of fine platinum particles with high surface area, commonly used in catalysis due to its exceptional activity and stability. Platinum Sponge is a porous, spongy form of platinum metal characterized by its lightweight structure and enhanced catalytic efficiency under various chemical reactions. Both materials are critical in industrial applications but differ primarily in morphology and surface properties, influencing their performance in fuel cells and chemical synthesis.

Chemical Composition and Structure

Platinum Black consists of finely divided platinum particles with a high surface area, offering superior catalytic activity due to its amorphous, porous structure. In contrast, Platinum Sponge features a more compact, sponge-like morphology composed of aggregated platinum crystallites, providing enhanced mechanical strength and stability. Both materials share the same chemical composition of pure platinum but differ significantly in their microstructure and surface properties, influencing their catalytic performance and applications.

Manufacturing Processes

Platinum Black is produced through chemical or electrochemical deposition, resulting in a highly porous and fine-grained material ideal for catalytic applications. In contrast, Platinum Sponge is manufactured by reducing platinum salts at high temperatures, creating a porous, lightweight form used primarily in powder metallurgy and refining. The differing manufacturing processes dictate their distinct microstructures and applications in industrial processes.

Surface Area and Porosity Comparison

Platinum black exhibits a highly porous structure with an extensive surface area, often exceeding 100 m2/g, which significantly enhances its catalytic activity compared to denser platinum sponge. Platinum sponge, while still porous, typically has a lower surface area, around 10-20 m2/g, resulting in reduced catalytic efficiency. The increased porosity and surface roughness of platinum black provide more active sites, making it preferable for applications requiring high reaction rates.

Catalytic Properties

Platinum black exhibits high catalytic activity due to its porous structure, providing a large surface area ideal for hydrogenation and oxidation reactions. Platinum sponge offers enhanced catalytic efficiency with superior mechanical strength and thermal stability, making it suitable for harsh industrial processes. Both forms excel in catalytic applications, but platinum sponge often demonstrates better durability and reusability under extreme conditions.

Applications in Industry

Platinum black, characterized by its high surface area and excellent catalytic properties, is widely used in electrochemical applications such as fuel cells, sensors, and electrolysis. Platinum sponge, with its porous structure and enhanced mechanical strength, finds extensive use in refining processes, chemical catalysis, and automotive catalytic converters. Both materials are critical in industrial catalysis, but platinum black excels in electrochemical reactions while platinum sponge is preferred for high-temperature and abrasive environments.

Durability and Stability

Platinum Black exhibits higher durability due to its robust nanostructured surface, which resists corrosion and mechanical wear better than Platinum Sponge. The stability of Platinum Black is enhanced by its dense morphology, providing more consistent electrochemical performance over extended use. In contrast, Platinum Sponge, while having a higher surface area, tends to degrade faster because of its porous structure, leading to reduced long-term stability.

Cost Implications

Platinum Black typically incurs higher costs due to its extensive processing and finer particle size, which enhances catalytic performance but demands more complex manufacturing. Platinum Sponge offers a cost-effective alternative with lower production expenses, owing to its simpler, porous structure used primarily in catalytic converters and industrial applications. Businesses often balance the superior activity of Platinum Black against the budget-friendly advantages of Platinum Sponge when determining procurement strategies.

Environmental Impact

Platinum Black and Platinum Sponge differ significantly in environmental impact due to their production methods and applications. Platinum Black, often synthesized through chemical reduction processes, can involve hazardous reagents leading to waste disposal challenges, whereas Platinum Sponge is typically produced via inert gas fusion or thermal decomposition, resulting in lower emissions and less chemical waste. The higher purity and catalytic efficiency of Platinum Sponge also contribute to reduced material consumption and longer catalyst lifespans, minimizing overall environmental footprint.

Choosing Between Platinum Black and Platinum Sponge

Platinum Black offers a high surface area and enhanced catalytic activity, making it ideal for applications requiring superior electrochemical performance such as fuel cells and sensors. Platinum Sponge, characterized by its porous and lightweight structure, provides excellent durability and is preferred in high-temperature environments and in chemical reactions where thermal resistance is critical. Selecting between Platinum Black and Platinum Sponge depends primarily on the specific application demands, including catalytic efficiency, temperature stability, and mechanical strength requirements.

Platinum Black vs Platinum Sponge Infographic

materialdif.com

materialdif.com