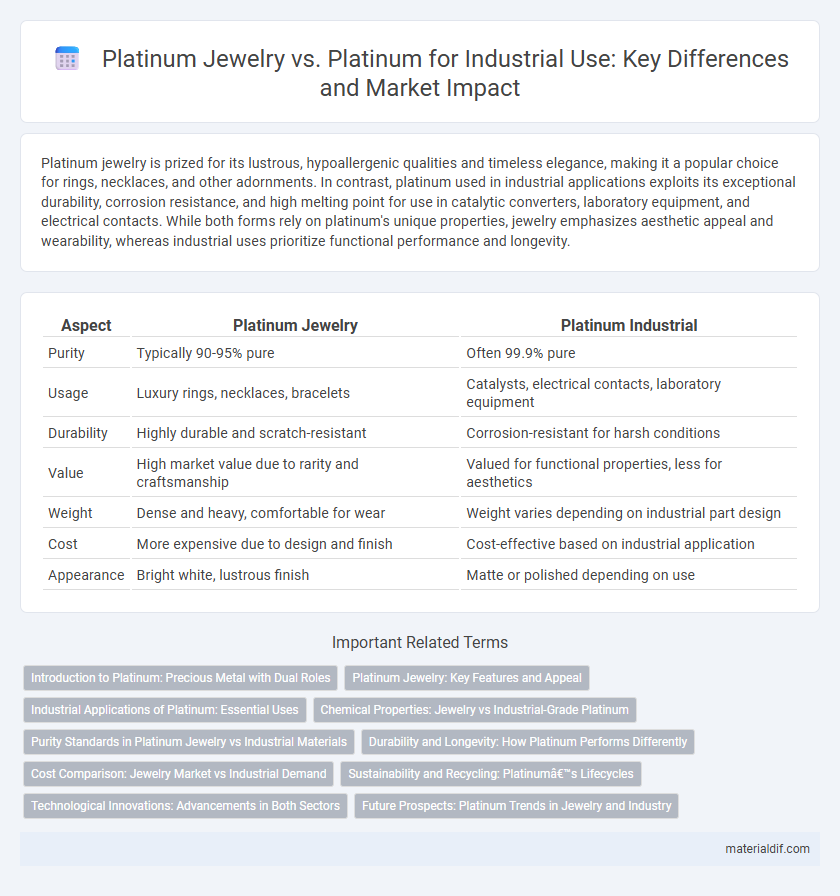

Platinum jewelry is prized for its lustrous, hypoallergenic qualities and timeless elegance, making it a popular choice for rings, necklaces, and other adornments. In contrast, platinum used in industrial applications exploits its exceptional durability, corrosion resistance, and high melting point for use in catalytic converters, laboratory equipment, and electrical contacts. While both forms rely on platinum's unique properties, jewelry emphasizes aesthetic appeal and wearability, whereas industrial uses prioritize functional performance and longevity.

Table of Comparison

| Aspect | Platinum Jewelry | Platinum Industrial |

|---|---|---|

| Purity | Typically 90-95% pure | Often 99.9% pure |

| Usage | Luxury rings, necklaces, bracelets | Catalysts, electrical contacts, laboratory equipment |

| Durability | Highly durable and scratch-resistant | Corrosion-resistant for harsh conditions |

| Value | High market value due to rarity and craftsmanship | Valued for functional properties, less for aesthetics |

| Weight | Dense and heavy, comfortable for wear | Weight varies depending on industrial part design |

| Cost | More expensive due to design and finish | Cost-effective based on industrial application |

| Appearance | Bright white, lustrous finish | Matte or polished depending on use |

Introduction to Platinum: Precious Metal with Dual Roles

Platinum, a rare and durable precious metal, holds significant value in both jewelry and industrial applications due to its exceptional corrosion resistance and malleability. In jewelry, platinum's lustrous white sheen and hypoallergenic properties make it a preferred choice for high-end pieces such as engagement rings and luxury watches. Industrially, platinum's remarkable catalytic properties and high melting point enable its use in automotive catalytic converters, chemical processing equipment, and electronics manufacturing.

Platinum Jewelry: Key Features and Appeal

Platinum jewelry is prized for its exceptional durability, natural white luster, and hypoallergenic properties, making it ideal for sensitive skin and everyday wear. Its rarity and resistance to tarnish enhance its value and appeal, often symbolizing luxury and timeless elegance in engagement rings and fine accessories. The metal's malleability allows jewelers to craft intricate designs while maintaining structural strength, distinguishing platinum pieces from other precious metals in the market.

Industrial Applications of Platinum: Essential Uses

Platinum's exceptional resistance to corrosion and high melting point make it indispensable in industrial applications such as catalytic converters, where it facilitates the reduction of harmful emissions in vehicles. Its unique catalytic properties also drive applications in chemical processing, including nitric acid production and silicone manufacture, optimizing efficiency and durability. In electronics, platinum is crucial for components requiring stable electrical conductivity and high-temperature endurance, underscoring its essential role across diverse industrial sectors.

Chemical Properties: Jewelry vs Industrial-Grade Platinum

Platinum jewelry typically contains 90-95% pure platinum alloyed with metals like iridium or ruthenium to enhance durability and resistance to scratching, ensuring long-lasting luster and hypoallergenic qualities. Industrial-grade platinum, often exceeding 99% purity, emphasizes maximum chemical inertness and corrosion resistance for applications in catalytic converters, laboratory equipment, and electronics where reactivity must be minimized. The key chemical distinction lies in the alloy composition that balances aesthetic appeal and wearability in jewelry against the high-purity, function-driven demands of industrial use.

Purity Standards in Platinum Jewelry vs Industrial Materials

Platinum jewelry typically boasts a purity standard of 90-95%, crafted for durability and hypoallergenic qualities, whereas industrial platinum often contains lower purity levels tailored for specific applications such as catalyst production or electrical components. The jewelry industry emphasizes alloying platinum with elements like ruthenium or iridium to enhance hardness without compromising the metal's signature luster. In contrast, industrial platinum materials sacrifice high purity for cost efficiency and functional properties required in sectors like automotive catalytic converters and electronics.

Durability and Longevity: How Platinum Performs Differently

Platinum jewelry is prized for its exceptional durability and resistance to tarnish, maintaining its luster and structural integrity over decades of wear. In industrial applications, platinum's high melting point and corrosion resistance enable it to withstand extreme temperatures and harsh chemical environments, ensuring long-term performance in catalytic converters and laboratory equipment. While both uses benefit from platinum's strength, jewelry emphasizes aesthetic longevity, whereas industrial uses capitalize on its robust physical and chemical stability.

Cost Comparison: Jewelry Market vs Industrial Demand

Platinum jewelry commands higher prices due to craftsmanship, design, and market demand for luxury goods, often leading to retail markups significantly above raw material costs. Industrial platinum prices tend to be more stable and are influenced by its applications in automotive catalytic converters, electronics, and chemical processing, with bulk purchasing lowering unit costs. The disparity between jewelry and industrial platinum pricing reflects differences in product value, processing complexity, and market segmentation.

Sustainability and Recycling: Platinum’s Lifecycles

Platinum jewelry and industrial applications both benefit from the metal's exceptional recyclability, significantly reducing environmental impact by minimizing mining demand. Platinum's unique properties allow it to be efficiently recovered and reused through sustainable recycling processes, preserving finite natural resources while supporting circular economies. The lifecycle of platinum in both sectors highlights its sustainability advantage, as recycled platinum maintains purity and performance without degradation.

Technological Innovations: Advancements in Both Sectors

Technological innovations in platinum jewelry include precision casting and surface treatments that enhance durability and aesthetic appeal, while industrial applications focus on catalytic converters, fuel cells, and medical devices utilizing platinum's exceptional corrosion resistance and conductivity. Advanced nanotechnology enables platinum nanoparticles to improve chemical reactions in industrial catalysts, whereas jewelry manufacturers leverage laser welding and computer-aided design for intricate, high-quality pieces. Both sectors benefit from ongoing research in platinum alloy development, balancing strength, flexibility, and functional efficiency for specialized uses.

Future Prospects: Platinum Trends in Jewelry and Industry

Platinum jewelry is poised to grow with rising consumer demand for luxury and sustainable materials, benefiting from innovations in crafting techniques and increasing awareness of platinum's hypoallergenic properties. Industrial applications of platinum are expanding rapidly in renewable energy sectors, especially in fuel cells and catalytic converters for green technologies, signaling robust future market growth. The synergy between aesthetic appeal in jewelry and functional utility in industry underscores platinum's versatile potential in evolving global markets.

Platinum Jewelry vs Platinum Industrial Infographic

materialdif.com

materialdif.com