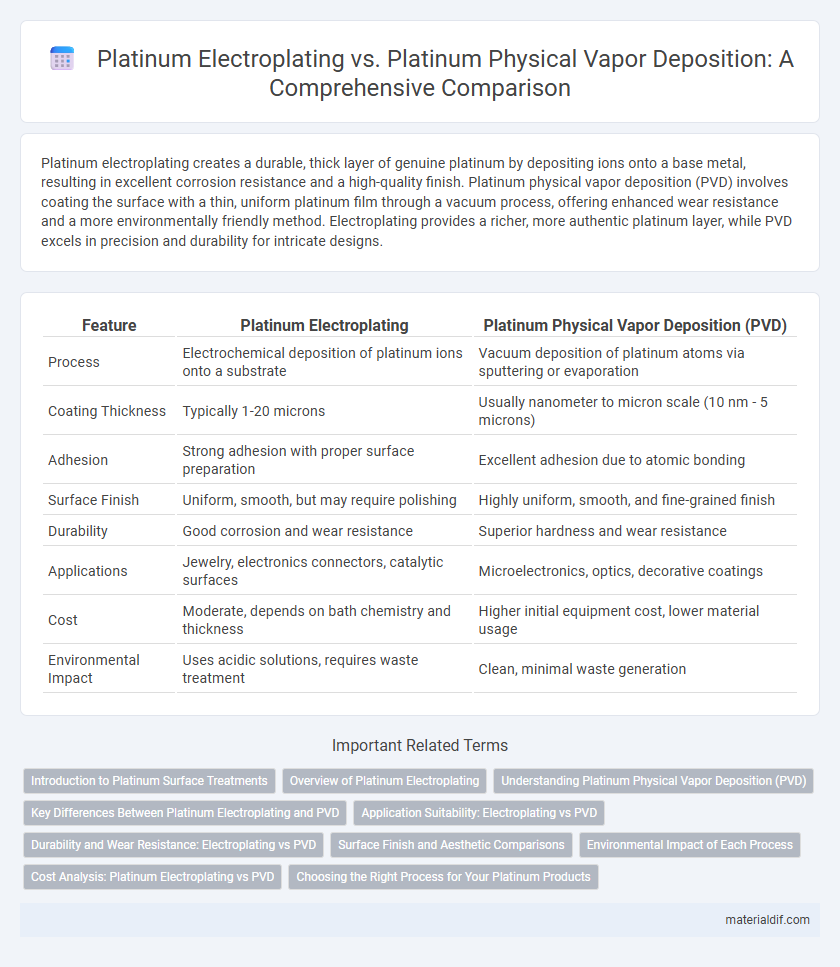

Platinum electroplating creates a durable, thick layer of genuine platinum by depositing ions onto a base metal, resulting in excellent corrosion resistance and a high-quality finish. Platinum physical vapor deposition (PVD) involves coating the surface with a thin, uniform platinum film through a vacuum process, offering enhanced wear resistance and a more environmentally friendly method. Electroplating provides a richer, more authentic platinum layer, while PVD excels in precision and durability for intricate designs.

Table of Comparison

| Feature | Platinum Electroplating | Platinum Physical Vapor Deposition (PVD) |

|---|---|---|

| Process | Electrochemical deposition of platinum ions onto a substrate | Vacuum deposition of platinum atoms via sputtering or evaporation |

| Coating Thickness | Typically 1-20 microns | Usually nanometer to micron scale (10 nm - 5 microns) |

| Adhesion | Strong adhesion with proper surface preparation | Excellent adhesion due to atomic bonding |

| Surface Finish | Uniform, smooth, but may require polishing | Highly uniform, smooth, and fine-grained finish |

| Durability | Good corrosion and wear resistance | Superior hardness and wear resistance |

| Applications | Jewelry, electronics connectors, catalytic surfaces | Microelectronics, optics, decorative coatings |

| Cost | Moderate, depends on bath chemistry and thickness | Higher initial equipment cost, lower material usage |

| Environmental Impact | Uses acidic solutions, requires waste treatment | Clean, minimal waste generation |

Introduction to Platinum Surface Treatments

Platinum electroplating involves depositing a thin layer of platinum onto a substrate through an electrochemical process, enhancing corrosion resistance and aesthetic appeal. In contrast, platinum physical vapor deposition (PVD) applies a platinum coating via vaporized atoms in a vacuum, resulting in a uniform, thin, and durable surface finish. Both surface treatments improve wear resistance and biocompatibility, but PVD offers superior adhesion and environmentally friendly processing compared to traditional electroplating.

Overview of Platinum Electroplating

Platinum electroplating involves depositing a thin layer of platinum onto a substrate using an electrochemical process, resulting in excellent corrosion resistance and enhanced surface durability. This method allows for precise control over the coating thickness and provides superior adhesion compared to other coating techniques, making it ideal for jewelry, electronics, and automotive components. Electroplated platinum offers a cost-effective alternative to solid platinum while maintaining aesthetic appeal and functional integrity.

Understanding Platinum Physical Vapor Deposition (PVD)

Platinum Physical Vapor Deposition (PVD) is a vacuum-based coating process that deposits a thin, uniform layer of platinum onto a substrate by vaporizing the metal into a plasma state and allowing it to condense on the target surface. This method offers superior adhesion, precise thickness control, and enhanced durability compared to traditional electroplating, making it ideal for high-performance industrial and decorative applications. PVD platinum coatings exhibit excellent corrosion resistance and maintain the metal's luster without the environmental concerns associated with chemical baths used in electroplating.

Key Differences Between Platinum Electroplating and PVD

Platinum electroplating involves depositing a thin layer of platinum onto a substrate through an electrochemical process, providing excellent corrosion resistance and a smooth, glossy finish ideal for jewelry and electronics. In contrast, Platinum Physical Vapor Deposition (PVD) uses a vacuum environment to vaporize platinum and coat surfaces at an atomic level, delivering a highly durable, scratch-resistant, and uniform film suitable for industrial applications and high-performance components. Key differences include the thickness and adhesion quality, with electroplating allowing thicker layers and PVD offering superior precision and environmental benefits due to less chemical waste.

Application Suitability: Electroplating vs PVD

Platinum electroplating is ideal for applications requiring a thick, corrosion-resistant coating, such as jewelry and automotive components, offering excellent adhesion and durability. Platinum physical vapor deposition (PVD) provides a thinner, more uniform coating ideal for electronics, medical devices, and precision instruments where surface finish and hardness are critical. Electroplating suits complex shapes and deep recesses better, while PVD excels in producing highly controlled, environmentally friendly coatings with superior wear resistance.

Durability and Wear Resistance: Electroplating vs PVD

Platinum electroplating involves depositing a thin layer of platinum onto a substrate, which offers good initial wear resistance but may wear off over time due to its relatively softer nature. Platinum Physical Vapor Deposition (PVD) creates a denser, more uniform coating through vaporized platinum atoms, resulting in superior durability and enhanced resistance to scratches and abrasion. PVD's atomic-level bonding provides a longer-lasting protective layer compared to the typically thinner and less resilient electroplated platinum surface.

Surface Finish and Aesthetic Comparisons

Platinum electroplating delivers a smooth, highly reflective surface finish with exceptional durability, making it ideal for fine jewelry and luxury watch components. In contrast, platinum physical vapor deposition (PVD) creates a uniform, thin film coating with a matte to satin appearance, offering enhanced scratch resistance and a modern aesthetic. While electroplating emphasizes brilliance and depth, PVD prioritizes longevity and consistent coloration, influencing the choice based on desired visual impact and wear characteristics.

Environmental Impact of Each Process

Platinum electroplating involves the use of toxic chemicals such as cyanide and acids, which generate hazardous waste requiring careful treatment to prevent environmental contamination. Platinum physical vapor deposition (PVD) offers a cleaner alternative by depositing thin platinum films in a vacuum chamber, significantly reducing chemical usage and waste production. The lower energy consumption and minimal hazardous byproducts of PVD make it a more environmentally sustainable choice compared to traditional electroplating methods.

Cost Analysis: Platinum Electroplating vs PVD

Platinum electroplating typically incurs lower initial equipment and setup costs compared to platinum physical vapor deposition (PVD), making it more cost-effective for small-scale applications. However, PVD offers superior material efficiency and uniform coating thickness, reducing long-term material costs and maintenance. Evaluating total cost of ownership, electroplating suits budget-conscious projects, while PVD is ideal for high-precision, high-volume production demanding consistent quality.

Choosing the Right Process for Your Platinum Products

Platinum electroplating provides a durable, corrosion-resistant coating ideal for intricate designs and jewelry, offering a more affordable option with excellent adhesion to substrates. Platinum physical vapor deposition (PVD) produces a thin, uniform, and environmentally friendly coating, enhancing surface hardness and wear resistance without the use of hazardous chemicals. Selecting between electroplating and PVD depends on the product's complexity, desired thickness, longevity, and environmental considerations for optimal performance and finish.

Platinum Electroplating vs Platinum Physical Vapor Deposition Infographic

materialdif.com

materialdif.com