Platinum electroplating involves coating a base metal with a thin layer of platinum, offering an affordable option with a striking appearance but less durability than solid platinum. Solid platinum items are composed entirely of pure platinum, ensuring exceptional strength, longevity, and resistance to tarnish, making them ideal for fine jewelry and investment pieces. While electroplated platinum offers a budget-friendly aesthetic, solid platinum provides unmatched value and lasting elegance.

Table of Comparison

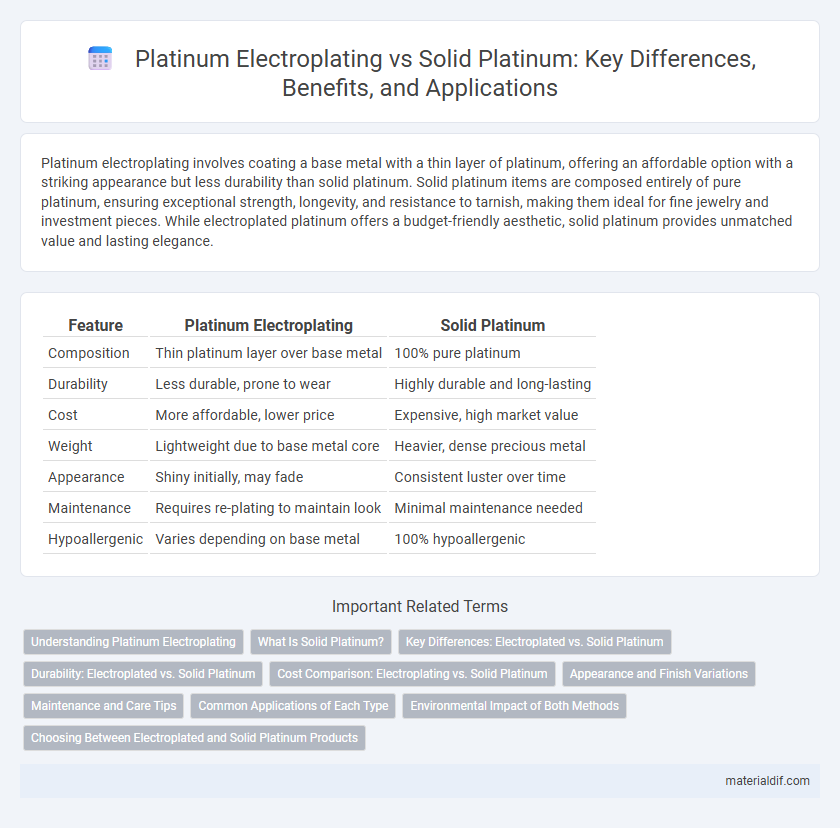

| Feature | Platinum Electroplating | Solid Platinum |

|---|---|---|

| Composition | Thin platinum layer over base metal | 100% pure platinum |

| Durability | Less durable, prone to wear | Highly durable and long-lasting |

| Cost | More affordable, lower price | Expensive, high market value |

| Weight | Lightweight due to base metal core | Heavier, dense precious metal |

| Appearance | Shiny initially, may fade | Consistent luster over time |

| Maintenance | Requires re-plating to maintain look | Minimal maintenance needed |

| Hypoallergenic | Varies depending on base metal | 100% hypoallergenic |

Understanding Platinum Electroplating

Platinum electroplating involves depositing a thin layer of platinum onto the surface of a base metal through an electrochemical process, enhancing the metal's corrosion resistance and aesthetic appeal without the cost of solid platinum. This method provides the visual and chemical benefits of platinum but lacks the durability and intrinsic value of solid platinum, which is composed entirely of the precious metal. Understanding the differences in composition, longevity, and cost helps consumers make informed decisions about the suitability of platinum electroplating versus solid platinum for jewelry or industrial applications.

What Is Solid Platinum?

Solid platinum is a pure precious metal used in jewelry and industrial applications, known for its durability, high density, and natural white luster. Unlike platinum electroplating, which involves applying a thin platinum layer over a base metal, solid platinum items are entirely composed of platinum, ensuring superior resistance to tarnish and wear. Its exceptional corrosion resistance and hypoallergenic properties make solid platinum highly valuable for fine jewelry and high-performance industrial components.

Key Differences: Electroplated vs. Solid Platinum

Platinum electroplating involves coating a base metal with a thin layer of platinum to achieve the appearance and corrosion resistance of solid platinum without the high cost. Solid platinum consists entirely of the metal, providing superior durability, natural hypoallergenic properties, and significant intrinsic value compared to electroplated items. The key difference lies in durability and value: solid platinum maintains its integrity through wear, while electroplated surfaces may eventually wear off, revealing the underlying metal.

Durability: Electroplated vs. Solid Platinum

Solid platinum offers superior durability compared to platinum electroplating, which can wear off over time due to its thin outer layer. Electroplated platinum provides an affordable, aesthetic finish but is prone to chipping and tarnishing with regular use. The longevity of solid platinum ensures resistance to scratching, corrosion, and everyday wear, making it ideal for long-lasting jewelry and industrial applications.

Cost Comparison: Electroplating vs. Solid Platinum

Platinum electroplating offers a cost-effective alternative to solid platinum by using a thin layer of platinum over a base metal, significantly reducing material expenses. Solid platinum items require a substantial amount of the precious metal, making their cost substantially higher due to the current market price of platinum, which hovers around $1,100 per ounce. While electroplated platinum provides aesthetic appeal at a fraction of the price, solid platinum ensures superior durability and long-term value, justifying the higher initial investment.

Appearance and Finish Variations

Platinum electroplating offers a bright, reflective finish that enhances jewelry with a smooth, high-gloss surface, though it may wear off over time, revealing underlying metals. Solid platinum, known for its naturally white luster and resistance to tarnish, maintains a consistent, durable finish that deepens in richness with wear. Differences in appearance are notable: electroplated platinum can mimic the look of solid platinum initially but lacks the enduring shine and weight that characterize solid pieces.

Maintenance and Care Tips

Platinum electroplating requires periodic reapplication to maintain its lustrous finish, as the thin plating layer can wear off over time with exposure to chemicals and friction. Solid platinum jewelry offers superior durability and resists tarnishing, requiring only occasional cleaning with mild soap and water to preserve its shine. Avoiding harsh chemicals and abrasive materials is essential for both to extend the longevity and appearance of platinum pieces.

Common Applications of Each Type

Platinum electroplating is widely used for enhancing the surface durability and corrosion resistance of jewelry, watches, and electronic components due to its thin yet protective coating. Solid platinum finds common applications in high-end jewelry, medical devices, and catalytic converters where its intrinsic strength, purity, and chemical stability are crucial. Both types offer unique benefits: electroplating provides a cost-effective way to achieve platinum's aesthetic and protective qualities, while solid platinum ensures maximum performance in demanding environments.

Environmental Impact of Both Methods

Platinum electroplating involves depositing a thin layer of platinum onto a base metal, significantly reducing the amount of platinum used and minimizing environmental extraction impacts. Solid platinum requires extensive mining and refining processes that generate higher carbon emissions and large quantities of waste compared to electroplating. Electroplating methods, when managed with modern waste treatment technologies, offer a more sustainable solution by conserving platinum resources and reducing environmental pollution.

Choosing Between Electroplated and Solid Platinum Products

Choosing between platinum electroplating and solid platinum depends on factors such as durability, cost, and intended use. Solid platinum offers superior longevity, resistance to wear, and intrinsic value due to its purity and density, making it ideal for fine jewelry and investment pieces. Platinum electroplating provides a more affordable option with a similar appearance but may wear off over time, requiring re-plating to maintain its finish.

Platinum Electroplating vs Solid Platinum Infographic

materialdif.com

materialdif.com