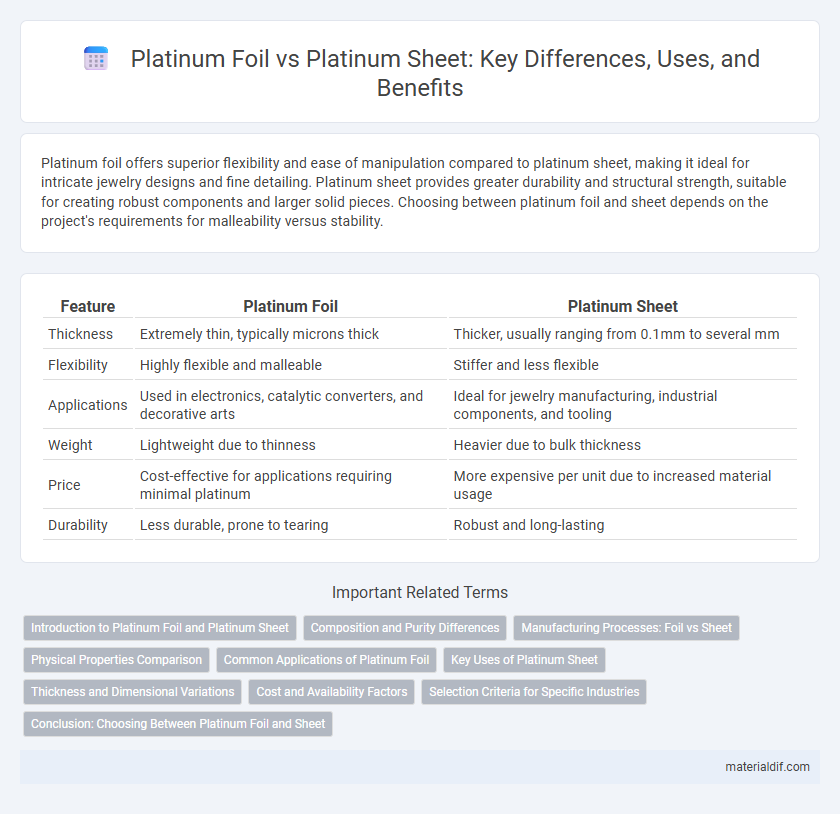

Platinum foil offers superior flexibility and ease of manipulation compared to platinum sheet, making it ideal for intricate jewelry designs and fine detailing. Platinum sheet provides greater durability and structural strength, suitable for creating robust components and larger solid pieces. Choosing between platinum foil and sheet depends on the project's requirements for malleability versus stability.

Table of Comparison

| Feature | Platinum Foil | Platinum Sheet |

|---|---|---|

| Thickness | Extremely thin, typically microns thick | Thicker, usually ranging from 0.1mm to several mm |

| Flexibility | Highly flexible and malleable | Stiffer and less flexible |

| Applications | Used in electronics, catalytic converters, and decorative arts | Ideal for jewelry manufacturing, industrial components, and tooling |

| Weight | Lightweight due to thinness | Heavier due to bulk thickness |

| Price | Cost-effective for applications requiring minimal platinum | More expensive per unit due to increased material usage |

| Durability | Less durable, prone to tearing | Robust and long-lasting |

Introduction to Platinum Foil and Platinum Sheet

Platinum foil and platinum sheet differ primarily in thickness and flexibility, with foil typically measuring less than 0.1 mm, offering exceptional pliability for intricate wrapping and fine laboratory applications. Platinum sheets are thicker, usually ranging from 0.1 mm to several millimeters, providing enhanced durability and strength for industrial uses such as catalysts, electrodes, and high-temperature components. Both forms maintain platinum's inherent corrosion resistance, high melting point (1,768degC), and excellent conductivity, making them essential in chemical, electronic, and medical industries.

Composition and Purity Differences

Platinum foil and platinum sheet differ primarily in thickness, but both maintain high purity levels typically ranging from 99.95% to 99.99%, essential for industrial and laboratory applications. The composition of platinum foil is consistent with that of platinum sheets; however, foils are rolled thinner, which can influence their mechanical properties and surface texture. Purity standards for both forms are stringent to ensure resistance to corrosion and consistent performance in catalytic converters and high-temperature environments.

Manufacturing Processes: Foil vs Sheet

Platinum foil is manufactured through cold rolling, which involves compressing platinum into thin, flexible layers ideal for delicate applications requiring high malleability. In contrast, platinum sheets are produced by hot rolling or forging, resulting in thicker, rigid forms used for structural or industrial purposes demanding higher strength. The difference in manufacturing processes directly affects the material's thickness, surface finish, and mechanical properties, making foil suitable for fine coatings and sheets for robust fabrication.

Physical Properties Comparison

Platinum foil exhibits greater malleability and thinner gauge compared to platinum sheet, allowing for easier shaping and intricate designs. Platinum sheets possess higher thickness and rigidity, making them more suitable for structural applications requiring durability and strength. Both forms share excellent corrosion resistance and high melting points, but the foil's flexibility contrasts with the sheet's solid resistance to deformation.

Common Applications of Platinum Foil

Platinum foil is widely used in laboratory crucibles, electrical contacts, and catalysis due to its excellent malleability and high melting point. Its thin, flexible nature allows precise heat transfer and resistance measurements in scientific and industrial applications. Unlike platinum sheets, foil is preferred in applications requiring lightweight, finely detailed metal layers for chemical processing and instrumentation.

Key Uses of Platinum Sheet

Platinum sheet is widely used in industries requiring high corrosion resistance and excellent thermal conductivity, such as in chemical processing equipment and electrical contacts. Its uniform thickness and strength make it ideal for precision applications like laboratory crucibles, heat exchangers, and semiconductor manufacturing. Unlike platinum foil, the sheet offers greater durability and structural integrity for demanding industrial environments.

Thickness and Dimensional Variations

Platinum foil typically ranges in thickness from 0.025 mm to 0.1 mm, offering superior flexibility for intricate wrapping and fine detailing applications. Platinum sheets, on the other hand, are generally thicker, starting at 0.1 mm and extending to several millimeters, providing greater rigidity and structural integrity for industrial and jewelry manufacturing. Dimensional variations in platinum foil are minimal due to precise rolling processes, while platinum sheets may exhibit broader size tolerances depending on production methods and intended use.

Cost and Availability Factors

Platinum foil typically costs less than platinum sheet due to its thinner gauge and lower material volume, making it more economical for intricate applications or layering. Availability of platinum foil is generally higher in specialized markets where fine, flexible materials are needed, whereas platinum sheets are produced in standard thicknesses and may have longer lead times due to manufacturing complexity. Both forms depend heavily on platinum market prices and supplier inventory, but sheets often require more raw platinum, impacting their overall cost and availability.

Selection Criteria for Specific Industries

Platinum foil offers superior flexibility and uniform thickness, making it ideal for electronics and catalytic converter manufacturing where precision and heat resistance are critical. Platinum sheet provides greater durability and structural integrity, preferred in jewelry making and chemical processing industries requiring robust corrosion resistance. Selecting between platinum foil and sheet depends on industry-specific requirements such as thickness tolerance, mechanical strength, and thermal conductivity.

Conclusion: Choosing Between Platinum Foil and Sheet

Selecting between platinum foil and platinum sheet depends on application precision and material thickness requirements. Platinum foil offers superior flexibility and is ideal for intricate or delicate tasks, while platinum sheets provide greater structural strength and uniformity suitable for more robust applications. Prioritizing project demands ensures the appropriate choice enhances both performance and cost-efficiency.

Platinum Foil vs Platinum Sheet Infographic

materialdif.com

materialdif.com