Hard platinum offers exceptional durability and resistance to scratching, making it ideal for everyday wear and long-lasting jewelry pieces. Soft platinum, on the other hand, is more malleable and easier to work with, allowing for intricate designs and detailed craftsmanship. Choosing between hard and soft platinum depends on whether toughness or design flexibility is the priority in platinum pet accessories or jewelry.

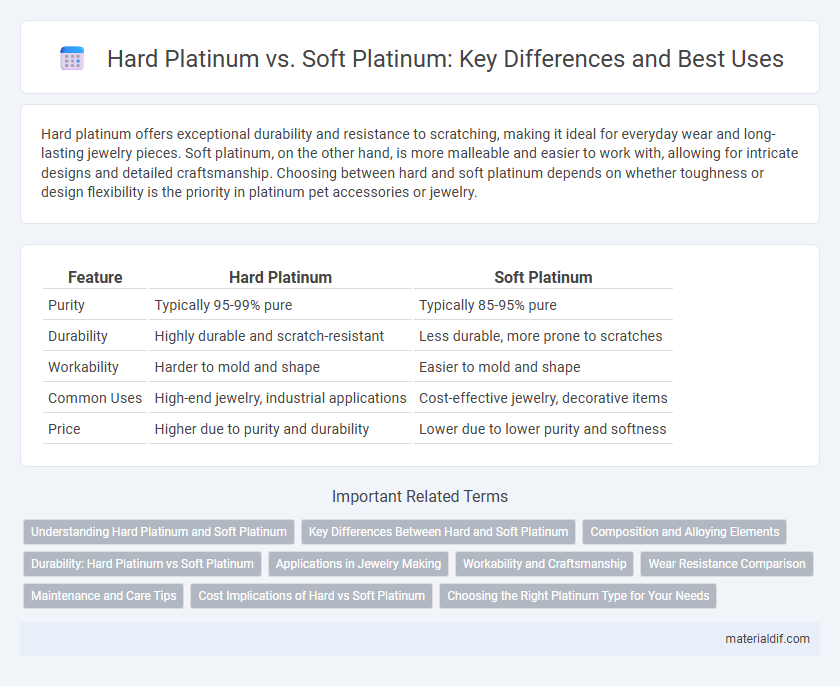

Table of Comparison

| Feature | Hard Platinum | Soft Platinum |

|---|---|---|

| Purity | Typically 95-99% pure | Typically 85-95% pure |

| Durability | Highly durable and scratch-resistant | Less durable, more prone to scratches |

| Workability | Harder to mold and shape | Easier to mold and shape |

| Common Uses | High-end jewelry, industrial applications | Cost-effective jewelry, decorative items |

| Price | Higher due to purity and durability | Lower due to lower purity and softness |

Understanding Hard Platinum and Soft Platinum

Hard platinum contains higher amounts of ruthenium or cobalt as alloying elements, enhancing its durability and scratch resistance, making it ideal for jewelry that withstands daily wear. Soft platinum is purer with minimal alloy content, offering superior malleability and a bright white finish, which is preferred for intricate designs and settings requiring detailed craftsmanship. Understanding the balance between hardness and purity is critical for selecting the appropriate platinum type based on application and desired longevity.

Key Differences Between Hard and Soft Platinum

Hard platinum alloys contain higher amounts of ruthenium, iridium, or cobalt, resulting in increased durability, scratch resistance, and strength compared to soft platinum. Soft platinum is nearly pure, typically 95-98% platinum, offering superior malleability and ease of crafting, ideal for intricate jewelry designs. The choice between hard and soft platinum depends on the desired balance between toughness and workability for specific applications.

Composition and Alloying Elements

Hard platinum typically contains higher concentrations of alloying elements such as ruthenium, cobalt, and iridium, which enhance its hardness and durability for industrial and jewelry applications. Soft platinum is composed predominantly of pure platinum with minimal alloying elements, resulting in increased malleability and a lustrous, smooth finish ideal for delicate designs. The variation in alloy composition directly influences the mechanical properties, with hard platinum alloys offering greater wear resistance and soft platinum providing superior workability.

Durability: Hard Platinum vs Soft Platinum

Hard platinum offers superior durability compared to soft platinum due to its higher alloy content, making it more resistant to scratches and deformation under daily wear. Soft platinum, typically purer with less alloy, provides greater malleability but is more prone to scratches and bending over time. Selecting hard platinum ensures long-lasting structural integrity, ideal for engagement rings and jewelry exposed to frequent use.

Applications in Jewelry Making

Hard platinum alloys, containing higher percentages of cobalt or ruthenium, offer enhanced durability and scratch resistance, making them ideal for intricate, everyday wearable jewelry such as engagement rings and wedding bands. Soft platinum, with a higher purity level of around 95-98%, is more malleable and preferred for delicate designs and artisan craftsmanship where detailed engraving or stone setting is required. Jewelers select hard platinum for functional pieces demanding long-term resilience, while soft platinum suits artistic creations that emphasize fine detail and customization.

Workability and Craftsmanship

Hard platinum offers superior durability and resistance to deformation, making it ideal for intricate designs requiring long-lasting structure. Soft platinum, while more malleable, allows for easier manipulation and detailed craftsmanship but may require additional care to maintain its shape. Jewelers often choose hard platinum for robust settings and soft platinum for delicate, finely detailed work to balance workability and aesthetic precision.

Wear Resistance Comparison

Hard platinum alloys exhibit superior wear resistance compared to soft platinum, making them ideal for applications requiring durability such as jewelry and industrial components. The increased hardness in hard platinum alloys is typically achieved by adding elements like ruthenium or cobalt, which enhance scratch resistance and maintain surface integrity under mechanical stress. Soft platinum, while more malleable and easier to work with, tends to show higher rates of abrasion and deformation over time, limiting its use in high-wear environments.

Maintenance and Care Tips

Hard platinum, containing a higher percentage of alloy metals like tungsten or cobalt, offers greater durability and resistance to scratches, making it ideal for everyday wear with minimal maintenance. Soft platinum, being purer and more malleable, requires gentle care to avoid bending or surface damage, necessitating regular professional cleaning and polishing to maintain its shine. Both types benefit from avoiding harsh chemicals and storing jewelry separately to prevent abrasion and preserve their natural luster.

Cost Implications of Hard vs Soft Platinum

Hard platinum alloys generally cost more than soft platinum due to the added metals such as ruthenium, iridium, or cobalt that enhance durability and scratch resistance. The increased manufacturing complexity and longer processing times associated with hard platinum raise production expenses, impacting the final price. Soft platinum, being easier to work with and less alloyed, tends to be more affordable but may incur higher maintenance costs over time due to its susceptibility to wear.

Choosing the Right Platinum Type for Your Needs

Hard platinum contains a higher percentage of ruthenium, making it more durable and scratch-resistant, ideal for engagement rings and jewelry subjected to daily wear. Soft platinum offers greater malleability and a smoother finish, preferred for intricate designs and custom pieces requiring detailed craftsmanship. Selecting the right platinum type depends on balancing durability needs with design complexity for optimal longevity and aesthetic appeal.

Hard Platinum vs Soft Platinum Infographic

materialdif.com

materialdif.com