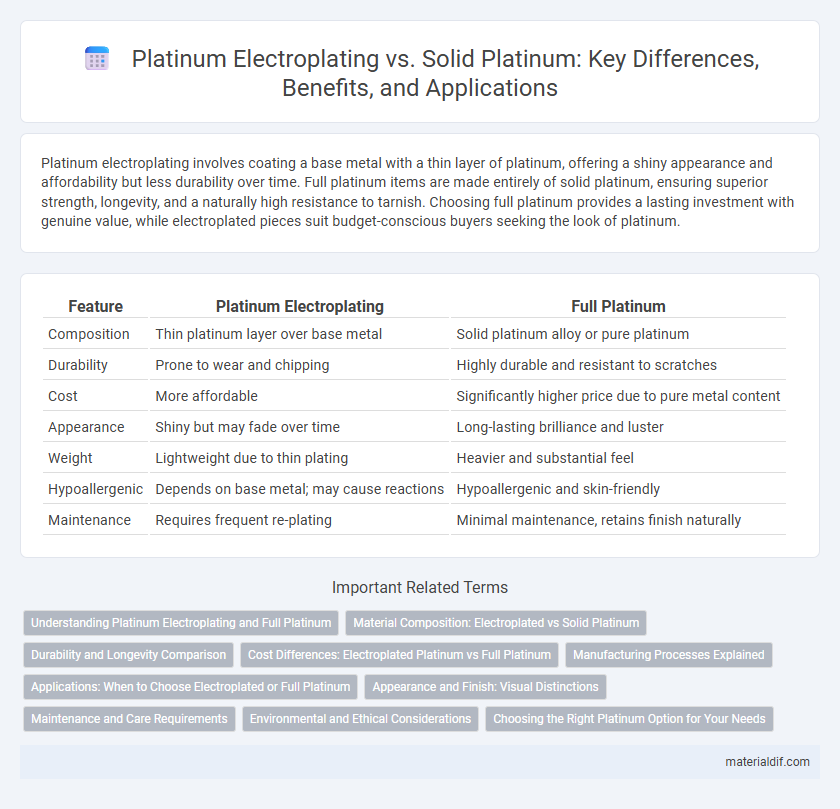

Platinum electroplating involves coating a base metal with a thin layer of platinum, offering a shiny appearance and affordability but less durability over time. Full platinum items are made entirely of solid platinum, ensuring superior strength, longevity, and a naturally high resistance to tarnish. Choosing full platinum provides a lasting investment with genuine value, while electroplated pieces suit budget-conscious buyers seeking the look of platinum.

Table of Comparison

| Feature | Platinum Electroplating | Full Platinum |

|---|---|---|

| Composition | Thin platinum layer over base metal | Solid platinum alloy or pure platinum |

| Durability | Prone to wear and chipping | Highly durable and resistant to scratches |

| Cost | More affordable | Significantly higher price due to pure metal content |

| Appearance | Shiny but may fade over time | Long-lasting brilliance and luster |

| Weight | Lightweight due to thin plating | Heavier and substantial feel |

| Hypoallergenic | Depends on base metal; may cause reactions | Hypoallergenic and skin-friendly |

| Maintenance | Requires frequent re-plating | Minimal maintenance, retains finish naturally |

Understanding Platinum Electroplating and Full Platinum

Platinum electroplating involves applying a thin layer of platinum onto the surface of another metal, enhancing corrosion resistance and aesthetic appeal without the cost of solid platinum. Full platinum refers to items made entirely from pure platinum, offering superior durability, value, and hypoallergenic properties. Understanding the distinction is crucial for consumers seeking balance between affordability and genuine platinum quality.

Material Composition: Electroplated vs Solid Platinum

Platinum electroplating involves a thin layer of platinum deposited onto a base metal, typically an alloy like brass or copper, resulting in a surface that mimics solid platinum but lacks its full material content. Solid platinum pieces are crafted entirely from platinum, usually 90% to 95% pure, offering superior durability and resistance to tarnish compared to electroplated items. The significant difference in platinum composition impacts weight, longevity, and value, with solid platinum providing authentic material properties absent in electroplated alternatives.

Durability and Longevity Comparison

Platinum electroplating offers a thin layer of platinum coating that enhances surface durability but is prone to wear and eventual exposure of the base metal over time. Full platinum items consist entirely of heavy, solid platinum, providing superior longevity and consistent resistance to tarnish, corrosion, and physical wear. When prioritizing durability and long-term value, full platinum delivers significantly greater performance than platinum electroplating.

Cost Differences: Electroplated Platinum vs Full Platinum

Platinum electroplating offers a more affordable alternative by coating a base metal with a thin layer of platinum, significantly reducing material costs compared to solid full platinum pieces. While full platinum items provide superior durability and intrinsic value due to their pure platinum content, their price is substantially higher because of the amount of platinum used. The cost difference can range from 50% to over 80%, making electroplating a cost-effective choice for platinum's luxurious appearance without the hefty investment.

Manufacturing Processes Explained

Platinum electroplating involves applying a thin layer of platinum onto a base metal through an electrochemical process, enhancing corrosion resistance and surface hardness while reducing costs. Full platinum manufacturing entails utilizing solid platinum material, requiring precision casting or forging techniques that ensure durability and intrinsic value. Electroplating offers cost efficiency and increased surface finish options, whereas full platinum production emphasizes purity and long-term wear resistance.

Applications: When to Choose Electroplated or Full Platinum

Platinum electroplating is ideal for applications requiring enhanced surface durability and corrosion resistance on less expensive base metals, commonly used in jewelry, automotive parts, and electronic connectors. Full platinum is preferred in high-end applications demanding superior chemical inertness, biocompatibility, and longevity, such as medical implants, catalytic converters, and luxury watch components. Choosing between electroplating and full platinum depends on budget constraints, performance requirements, and the specific environmental conditions of the application.

Appearance and Finish: Visual Distinctions

Platinum electroplating provides a thin, lustrous layer that enhances the base metal's sheen with a bright, reflective surface but can eventually wear off, exposing the underlying material. Full platinum items display a deeper, natural white-silver color with a heavier, more substantial feel, offering superior durability and resistance to tarnish and scratches. The visual distinction is evident in the finish quality, where full platinum maintains a consistent, rich appearance over time, unlike the thinner, more delicate coating of electroplated pieces.

Maintenance and Care Requirements

Platinum electroplating requires regular maintenance, including gentle cleaning to prevent the thin platinum layer from wearing off and exposing the base metal underneath. Full platinum items, being solid, are more durable and resist tarnishing, needing less frequent polishing and offering longer-lasting surface protection. Proper care of electroplated pieces involves avoiding abrasive materials, while full platinum jewelry withstands daily wear with minimal upkeep.

Environmental and Ethical Considerations

Platinum electroplating uses a thin layer of platinum over base metals, significantly reducing the amount of platinum required and minimizing environmental impact due to lower mining demand. Full platinum jewelry, made entirely of platinum, involves extensive mining, contributing to higher ecological disruption and potential ethical concerns around resource extraction. Choosing electroplated platinum supports sustainable practices by conserving natural resources while maintaining the aesthetic of platinum.

Choosing the Right Platinum Option for Your Needs

Platinum electroplating offers a cost-effective way to achieve the luxurious appearance of platinum with a thin, durable layer over a base metal, ideal for budget-conscious buyers seeking aesthetic appeal and corrosion resistance. Full platinum items provide superior durability, hypoallergenic properties, and intrinsic value, making them suitable for long-term investment or high-wear jewelry. Assessing factors like budget, usage frequency, and desired longevity helps in choosing between the affordability of electroplated platinum and the enduring quality of solid platinum.

Platinum Electroplating vs Full Platinum Infographic

materialdif.com

materialdif.com