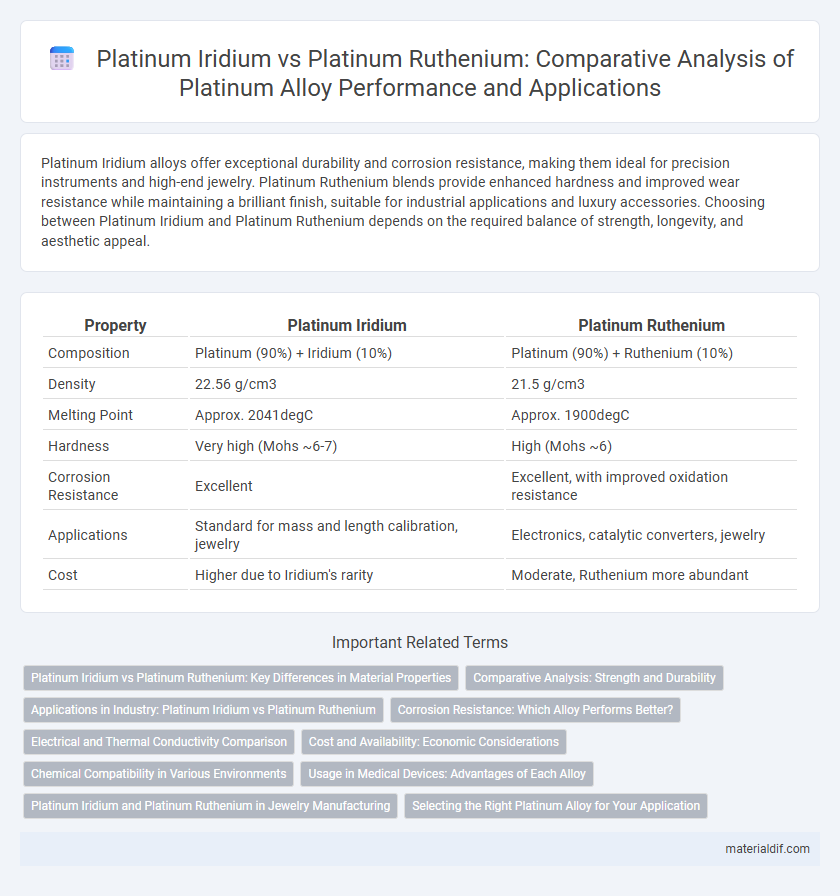

Platinum Iridium alloys offer exceptional durability and corrosion resistance, making them ideal for precision instruments and high-end jewelry. Platinum Ruthenium blends provide enhanced hardness and improved wear resistance while maintaining a brilliant finish, suitable for industrial applications and luxury accessories. Choosing between Platinum Iridium and Platinum Ruthenium depends on the required balance of strength, longevity, and aesthetic appeal.

Table of Comparison

| Property | Platinum Iridium | Platinum Ruthenium |

|---|---|---|

| Composition | Platinum (90%) + Iridium (10%) | Platinum (90%) + Ruthenium (10%) |

| Density | 22.56 g/cm3 | 21.5 g/cm3 |

| Melting Point | Approx. 2041degC | Approx. 1900degC |

| Hardness | Very high (Mohs ~6-7) | High (Mohs ~6) |

| Corrosion Resistance | Excellent | Excellent, with improved oxidation resistance |

| Applications | Standard for mass and length calibration, jewelry | Electronics, catalytic converters, jewelry |

| Cost | Higher due to Iridium's rarity | Moderate, Ruthenium more abundant |

Platinum Iridium vs Platinum Ruthenium: Key Differences in Material Properties

Platinum Iridium exhibits higher corrosion resistance and enhanced hardness compared to Platinum Ruthenium, making it ideal for applications requiring durability under harsh conditions. Platinum Ruthenium offers superior electrical conductivity and excellent catalytic properties, favored in fuel cell technology and automotive catalytic converters. Differences in density and melting points also influence their selection; Platinum Iridium is denser and melts at a slightly higher temperature, affecting performance in high-temperature environments.

Comparative Analysis: Strength and Durability

Platinum iridium alloys exhibit superior tensile strength and resistance to corrosion compared to platinum ruthenium alloys, making them ideal for high-stress industrial applications. Platinum ruthenium, while offering moderate hardness and good oxidation resistance, tends to possess lower durability under extreme mechanical wear. The enhanced strength of platinum iridium alloys results from iridium's dense atomic structure, which significantly improves overall alloy resilience.

Applications in Industry: Platinum Iridium vs Platinum Ruthenium

Platinum iridium alloys are prized in precision measurement instruments and standard weights due to their exceptional hardness, corrosion resistance, and stability under varying environmental conditions. Platinum ruthenium alloys, conversely, excel in electrical applications like fuel cell electrodes and catalytic converters, benefiting from enhanced catalytic activity and resistance to oxidation at high temperatures. Industries select platinum iridium for durability in metrology and platinum ruthenium for improved electrochemical performance in energy and automotive sectors.

Corrosion Resistance: Which Alloy Performs Better?

Platinum iridium alloy exhibits superior corrosion resistance compared to platinum ruthenium due to the high chemical stability of iridium, which enhances durability in harsh environments. Platinum ruthenium, while offering good resistance, is more prone to oxidation and surface degradation under aggressive chemical exposure. Industrial applications requiring extreme corrosion resistance typically favor platinum iridium alloys for longer lifespan and reliability.

Electrical and Thermal Conductivity Comparison

Platinum iridium alloys exhibit excellent electrical conductivity, typically around 20-25% IACS (International Annealed Copper Standard), with superior thermal conductivity approximately 70 W/m*K, making them suitable for precision electrical contacts and high-temperature applications. In contrast, platinum ruthenium alloys offer slightly lower electrical conductivity, generally near 15-20% IACS, but enhanced thermal stability and corrosion resistance, with thermal conductivity around 50-60 W/m*K, which benefits fuel cell and catalytic converter components. The trade-off between electrical and thermal conductivity in these alloys directly influences their performance in specialized industrial and electronic applications.

Cost and Availability: Economic Considerations

Platinum Iridium alloys typically cost more than Platinum Ruthenium due to the rarity and higher market value of iridium. Availability of iridium is limited, resulting in supply constraints that increase overall expenses compared to the more abundant ruthenium. Economic considerations favor Platinum Ruthenium for cost-sensitive applications where wider availability and lower price are critical factors.

Chemical Compatibility in Various Environments

Platinum-Iridium alloys exhibit exceptional chemical compatibility, maintaining stability in aggressive environments such as strong acids and high temperatures, making them ideal for scientific and industrial applications requiring corrosion resistance. Platinum-Ruthenium combinations offer enhanced resistance to oxidation and excellent durability in fuel cell catalysts and electrochemical environments, particularly in acidic and alkaline conditions. Both alloys demonstrate superior chemical inertness compared to pure platinum, but selection depends on the specific environmental factors and performance requirements of the application.

Usage in Medical Devices: Advantages of Each Alloy

Platinum iridium alloys are favored in medical devices for their exceptional biocompatibility and superior corrosion resistance, making them ideal for long-term implants such as pacemaker electrodes and neural probes. Platinum ruthenium alloys offer enhanced electrical conductivity and mechanical strength, which are advantageous in applications requiring precise electrical performance and durability, like cochlear implants and fine surgical instruments. Both alloys ensure reliable performance in critical medical environments, but the choice depends on the specific device requirements, balancing biocompatibility with electrical and mechanical properties.

Platinum Iridium and Platinum Ruthenium in Jewelry Manufacturing

Platinum Iridium alloys are favored in jewelry manufacturing for their exceptional hardness and long-lasting luster, making them ideal for intricate designs and daily wear. Platinum Ruthenium, while less common, offers enhanced corrosion resistance and a distinctive silvery-white hue that is attractive in high-end jewelry settings. Both alloys provide superior durability compared to pure platinum, but Platinum Iridium remains the preferred choice for creating durable and elegant pieces with intricate detailing.

Selecting the Right Platinum Alloy for Your Application

Platinum Iridium alloys offer exceptional hardness and corrosion resistance, making them ideal for precision instruments and medical devices requiring durability and biocompatibility. Platinum Ruthenium alloys provide enhanced catalytic properties and thermal stability, suited for industrial applications such as fuel cells and high-temperature electrodes. Selecting the right platinum alloy depends on balancing mechanical strength, chemical resistance, and specific functional requirements of your application.

Platinum Iridium vs Platinum Ruthenium Infographic

materialdif.com

materialdif.com