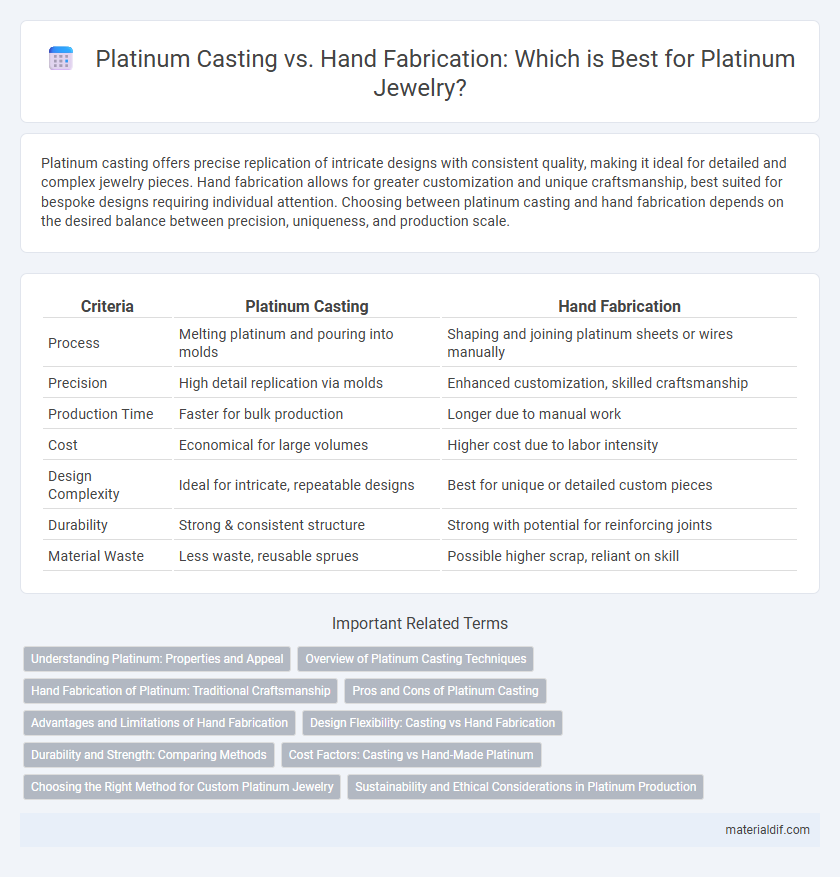

Platinum casting offers precise replication of intricate designs with consistent quality, making it ideal for detailed and complex jewelry pieces. Hand fabrication allows for greater customization and unique craftsmanship, best suited for bespoke designs requiring individual attention. Choosing between platinum casting and hand fabrication depends on the desired balance between precision, uniqueness, and production scale.

Table of Comparison

| Criteria | Platinum Casting | Hand Fabrication |

|---|---|---|

| Process | Melting platinum and pouring into molds | Shaping and joining platinum sheets or wires manually |

| Precision | High detail replication via molds | Enhanced customization, skilled craftsmanship |

| Production Time | Faster for bulk production | Longer due to manual work |

| Cost | Economical for large volumes | Higher cost due to labor intensity |

| Design Complexity | Ideal for intricate, repeatable designs | Best for unique or detailed custom pieces |

| Durability | Strong & consistent structure | Strong with potential for reinforcing joints |

| Material Waste | Less waste, reusable sprues | Possible higher scrap, reliant on skill |

Understanding Platinum: Properties and Appeal

Platinum casting offers precision and consistency by melting and pouring the metal into molds, ideal for intricate designs requiring uniformity. Hand fabrication involves manually shaping and assembling platinum pieces, allowing for customized, artisanal craftsmanship with exceptional control over detail. Platinum's high density (21.45 g/cm3), excellent corrosion resistance, and natural white luster contribute to its appeal in both casting and fabrication, ensuring durability and timeless elegance.

Overview of Platinum Casting Techniques

Platinum casting techniques primarily include lost-wax casting and centrifugal casting, which allow precise molding of intricate designs by melting platinum and pouring it into detailed molds. Lost-wax casting offers exceptional detail and complex shapes, making it ideal for fine jewelry, while centrifugal casting uses centrifugal force to ensure metal fills every detail of the mold. Both methods are favored for their ability to produce high-quality platinum pieces with excellent strength and durability.

Hand Fabrication of Platinum: Traditional Craftsmanship

Hand fabrication of platinum emphasizes meticulous traditional craftsmanship, involving precise techniques like soldering, shaping, and welding by skilled artisans. This method allows for intricate, custom designs that highlight the metal's natural strength and durability without the limitations of casting molds. Artisans can achieve superior detail and a refined finish, making hand-fabricated platinum jewelry highly valued for its uniqueness and structural integrity.

Pros and Cons of Platinum Casting

Platinum casting offers superior precision in replicating intricate designs and allows for efficient mass production, making it ideal for complex jewelry pieces. However, casting involves higher initial costs due to mold creation and may introduce porosity issues affecting the metal's strength and finish. While casting facilitates consistency and scalability, it lacks the artisanal uniqueness and potential customization found in hand fabrication.

Advantages and Limitations of Hand Fabrication

Hand fabrication of platinum offers superior precision and customization, enabling intricate designs and detailed craftsmanship that casting cannot easily replicate. Its limitations include higher labor costs and longer production time, which may not be efficient for large-scale or uniform pieces. Despite these challenges, hand fabrication provides enhanced structural integrity and better control over material properties compared to platinum casting.

Design Flexibility: Casting vs Hand Fabrication

Platinum casting offers superior design flexibility by allowing intricate and complex shapes to be produced with high precision, ideal for detailed jewelry pieces. Hand fabrication, while more labor-intensive, provides bespoke customization and the ability to make adjustments during the crafting process, appealing to artisans seeking unique, one-of-a-kind designs. Both methods optimize platinum's strength and malleability, but casting excels in replicating precise patterns while hand fabrication shines in personalized craftsmanship.

Durability and Strength: Comparing Methods

Platinum casting offers consistent density and uniform strength due to precise mold creation, resulting in durable jewelry resistant to wear and deformation. Hand fabrication allows for meticulous craftsmanship with reinforced joints, enhancing structural integrity through skilled soldering techniques. Both methods yield strong platinum pieces, but casting typically ensures greater homogeneity, while hand fabrication provides customized strength in critical areas.

Cost Factors: Casting vs Hand-Made Platinum

Platinum casting generally offers cost efficiency through mass production, reducing labor expenses compared to hand fabrication. Hand-made platinum pieces demand skilled craftsmanship and extended labor hours, significantly increasing overall costs due to the intricate detailing and customization involved. Casting methods optimize material usage and minimize waste, while hand fabrication often results in higher platinum consumption and greater financial investment.

Choosing the Right Method for Custom Platinum Jewelry

Platinum casting allows for intricate and consistent designs by melting and pouring the metal into precise molds, making it ideal for complex or mass-produced custom jewelry. Hand fabrication offers superior control and detail through meticulous shaping and soldering, perfect for unique, one-of-a-kind pieces that require artisan craftsmanship. Selecting between casting and hand fabrication depends on factors like design complexity, budget, and desired finish quality in custom platinum jewelry creation.

Sustainability and Ethical Considerations in Platinum Production

Platinum casting involves melting and molding recycled or newly mined platinum, which can lower environmental impact through material reuse and efficient energy consumption. Hand fabrication, while often producing less waste, relies heavily on skilled artisans and may require more energy-intensive tools, affecting sustainability differently. Ethical considerations in both methods emphasize sourcing platinum from conflict-free mines and promoting fair labor practices throughout the supply chain.

Platinum Casting vs Hand Fabrication Infographic

materialdif.com

materialdif.com