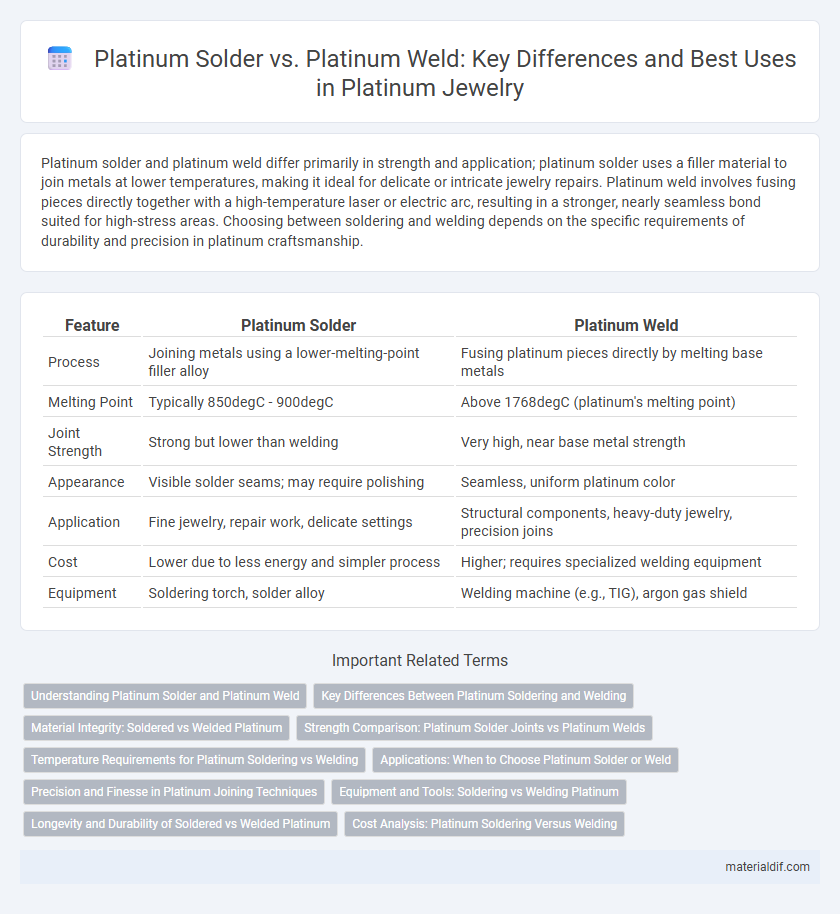

Platinum solder and platinum weld differ primarily in strength and application; platinum solder uses a filler material to join metals at lower temperatures, making it ideal for delicate or intricate jewelry repairs. Platinum weld involves fusing pieces directly together with a high-temperature laser or electric arc, resulting in a stronger, nearly seamless bond suited for high-stress areas. Choosing between soldering and welding depends on the specific requirements of durability and precision in platinum craftsmanship.

Table of Comparison

| Feature | Platinum Solder | Platinum Weld |

|---|---|---|

| Process | Joining metals using a lower-melting-point filler alloy | Fusing platinum pieces directly by melting base metals |

| Melting Point | Typically 850degC - 900degC | Above 1768degC (platinum's melting point) |

| Joint Strength | Strong but lower than welding | Very high, near base metal strength |

| Appearance | Visible solder seams; may require polishing | Seamless, uniform platinum color |

| Application | Fine jewelry, repair work, delicate settings | Structural components, heavy-duty jewelry, precision joins |

| Cost | Lower due to less energy and simpler process | Higher; requires specialized welding equipment |

| Equipment | Soldering torch, solder alloy | Welding machine (e.g., TIG), argon gas shield |

Understanding Platinum Solder and Platinum Weld

Platinum solder is a high-temperature alloy used to join platinum pieces with precise control, creating strong, seamless bonds often achieved through heating below the melting point of the base metal. Platinum welding involves the fusion of platinum parts by direct application of intense heat, typically with a torch or laser, allowing for repair or fabrication without adding filler materials. Understanding the distinction between platinum solder and platinum weld is crucial for selecting the appropriate technique based on joint strength, appearance, and thermal impact on the platinum alloy.

Key Differences Between Platinum Soldering and Welding

Platinum soldering involves joining metals using a filler alloy with a lower melting point than platinum, ensuring minimal distortion and precise control for delicate applications. Platinum welding fuses platinum pieces directly by melting the base metal, creating stronger, seamless joints ideal for high-stress environments. Key differences include temperature ranges, with soldering operating below 1,200degC and welding requiring temperatures above platinum's melting point (1,768degC), and the resulting joint strength and heat-affected zones.

Material Integrity: Soldered vs Welded Platinum

Platinum soldering involves joining metals by melting a filler metal with a lower melting point, which can introduce potential weak points and reduced corrosion resistance at the joint, affecting overall material integrity. Welding platinum fuses the base metals directly, creating a seamless bond that preserves the metal's high strength, durability, and resistance to oxidation. Consequently, welded platinum typically maintains superior material integrity compared to soldered platinum, especially in applications requiring maximum structural stability and longevity.

Strength Comparison: Platinum Solder Joints vs Platinum Welds

Platinum welds exhibit superior strength compared to platinum solder joints due to the metal's complete fusion during the welding process, creating a seamless bond that matches the base material's durability. Platinum solder joints rely on a filler metal with a lower melting point, resulting in weaker tensile strength and reduced resistance to mechanical stress. For applications demanding maximum structural integrity and longevity, platinum welds are preferred over soldered connections.

Temperature Requirements for Platinum Soldering vs Welding

Platinum soldering requires temperatures typically between 800degC and 950degC, enabling the use of low-melting-point filler metals that bond without melting the base metal. In contrast, platinum welding demands much higher temperatures, often exceeding 1500degC, to fuse the platinum pieces directly through localized melting. The precise temperature control in soldering preserves the integrity of delicate components, whereas welding provides stronger, more durable joints for heavy-duty applications.

Applications: When to Choose Platinum Solder or Weld

Platinum solder is ideal for delicate applications requiring low heat to join fine jewelry or small electronic components without damaging surrounding materials. Platinum weld provides a stronger, more durable bond suited for structural repairs, high-stress industrial parts, and medical instruments where maximum strength and resistance to corrosion are critical. Choose solder for precision joining and weld for heavy-duty, high-performance connections in platinum craftsmanship and manufacturing.

Precision and Finesse in Platinum Joining Techniques

Platinum soldering offers exceptional precision through controlled melting points, allowing intricate and delicate joinery without compromising the metal's integrity. Platinum welding, using laser or resistance techniques, provides superior strength and seamless joints but demands higher technical skill to achieve finesse. Both methods enhance platinum craftsmanship, with soldering excelling in detailed work and welding suited for robust, precision-critical assemblies.

Equipment and Tools: Soldering vs Welding Platinum

Platinum soldering requires precise temperature-controlled soldering irons or torches and specialized platinum solder alloys, allowing delicate joins without melting the base metal. Platinum welding demands high-powered TIG or laser welding equipment that produces intense heat to fuse platinum pieces directly, ensuring superior strength and durability. Soldering tools emphasize finesse and low heat application, while welding equipment focuses on controlled high temperatures and shielding gases to maintain metal integrity.

Longevity and Durability of Soldered vs Welded Platinum

Platinum welds typically offer superior longevity and durability compared to soldered joints, as the welding process fuses the metal at a molecular level, creating a stronger and more seamless bond. Soldered platinum connections rely on filler metals that may weaken over time, especially under stress or exposure to heat and chemicals. For applications requiring maximum strength and extended lifespan, welded platinum components provide a more reliable and long-lasting solution.

Cost Analysis: Platinum Soldering Versus Welding

Platinum soldering generally incurs lower upfront costs due to reduced equipment requirements and faster processing times compared to platinum welding, which demands specialized machinery and skilled labor. The cost of consumables in soldering, such as solder alloys, is typically less expensive than maintaining welding supplies and gas mixtures necessary for welding. Long-term expenses may favor welding for high-strength or precision applications because of its superior joint integrity, reducing the likelihood of repairs or failures over time.

Platinum Solder vs Platinum Weld Infographic

materialdif.com

materialdif.com