Platinum inlays provide a durable and long-lasting enhancement by embedding pure platinum directly into the surface, offering superior resistance to wear and corrosion compared to coatings. Platinum coatings, while visually appealing and more affordable, tend to wear off over time and require reapplication to maintain their protective and aesthetic qualities. Choosing a platinum inlay ensures a more permanent and resilient solution for pet accessories, delivering unparalleled elegance and strength.

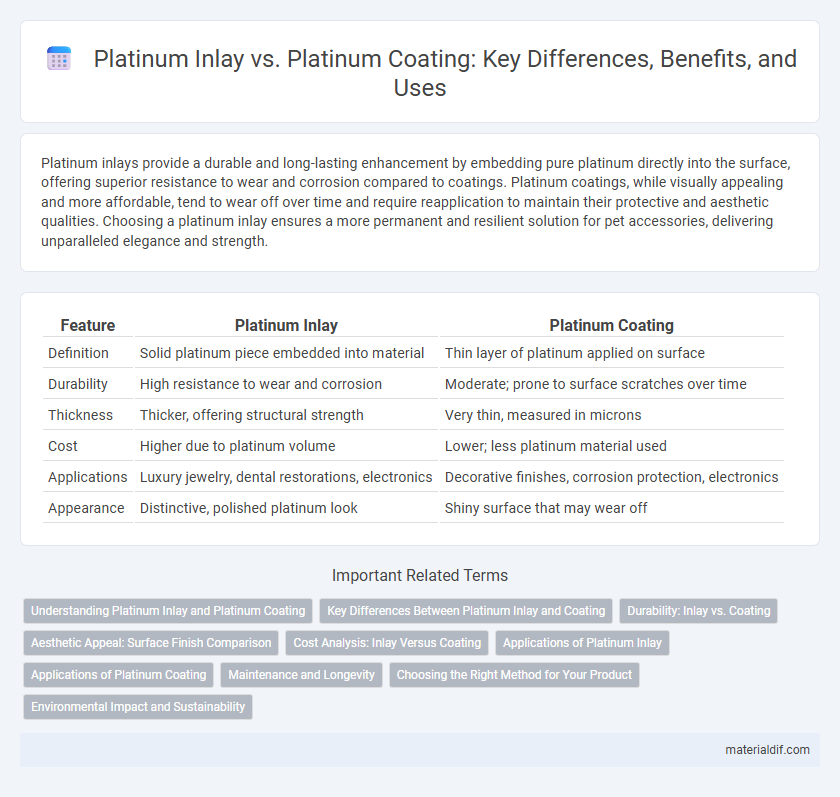

Table of Comparison

| Feature | Platinum Inlay | Platinum Coating |

|---|---|---|

| Definition | Solid platinum piece embedded into material | Thin layer of platinum applied on surface |

| Durability | High resistance to wear and corrosion | Moderate; prone to surface scratches over time |

| Thickness | Thicker, offering structural strength | Very thin, measured in microns |

| Cost | Higher due to platinum volume | Lower; less platinum material used |

| Applications | Luxury jewelry, dental restorations, electronics | Decorative finishes, corrosion protection, electronics |

| Appearance | Distinctive, polished platinum look | Shiny surface that may wear off |

Understanding Platinum Inlay and Platinum Coating

Platinum inlay involves embedding pure platinum directly into a material, creating a durable and wear-resistant design with depth and texture. Platinum coating refers to applying a thin layer of platinum on the surface, enhancing corrosion resistance and aesthetic appeal without altering the base material's structure. Both techniques leverage platinum's unique chemical stability and lustrous finish, but inlays provide structural reinforcement while coatings offer surface protection.

Key Differences Between Platinum Inlay and Coating

Platinum inlay involves embedding solid platinum pieces directly into a material for enhanced durability and luxurious appearance, while platinum coating applies a thin platinum layer on the surface, offering corrosion resistance and aesthetic appeal with less material cost. Inlays provide greater longevity and are ideal for high-wear applications, whereas coatings serve as protective finishes that improve surface hardness and brightness but may wear off over time. The choice between inlay and coating depends on the desired balance between durability, cost, and visual effect.

Durability: Inlay vs. Coating

Platinum inlays exhibit superior durability compared to platinum coatings due to their solid metal composition and integration into the base material, providing enhanced resistance to wear, corrosion, and mechanical stress. Platinum coatings, being thin layers applied on surfaces, are more susceptible to abrasion and gradual thinning, reducing their protective effectiveness over time. For long-term applications requiring robust performance, platinum inlays offer a more reliable and enduring solution than platinum coatings.

Aesthetic Appeal: Surface Finish Comparison

Platinum inlay offers a rich, three-dimensional aesthetic with a highly polished surface that enhances depth and brilliance, making it ideal for intricate jewelry pieces. Platinum coating provides a smooth, reflective finish that can improve the overall shine of base metals but lacks the layered texture and durability of an inlay. The inlay's substantial surface retains its luster longer under wear, while coatings may fade or tarnish over time, impacting long-term aesthetic appeal.

Cost Analysis: Inlay Versus Coating

Platinum inlays generally incur higher initial costs due to the intricate metalwork and customization required compared to platinum coating, which applies a thin platinum layer over a substrate. Over time, inlays offer superior durability and longevity, potentially reducing replacement or repair expenses, whereas coatings may require periodic reapplication to maintain their appearance and protective qualities. Cost-effectiveness depends on the item's intended use, with inlays favored for high-wear applications and coatings suitable for aesthetic enhancement at a lower upfront investment.

Applications of Platinum Inlay

Platinum inlay is predominantly used in fine jewelry and high-precision instruments due to its superior durability and corrosion resistance, ensuring long-lasting embellishments and structural integrity. Unlike platinum coating, which provides a thin surface layer prone to wear, inlays embed platinum directly into the base material for enhanced strength and aesthetic appeal. This makes platinum inlays ideal for luxury watches, medical devices, and aerospace components where permanent, high-quality performance is crucial.

Applications of Platinum Coating

Platinum coating is widely used in electronic components and catalytic converters due to its excellent corrosion resistance and high catalytic activity. It is favored in biomedical implants and sensors for its biocompatibility and durability under harsh conditions. Industrial applications also include protective coatings on turbine blades and chemical processing equipment to enhance longevity and performance.

Maintenance and Longevity

Platinum inlays offer superior durability and require minimal maintenance compared to platinum coatings, which can wear off or tarnish over time. Inlays are integrated into the structure, providing long-lasting protection against corrosion and scratches, while coatings may need periodic reapplication to maintain their appearance. Choosing platinum inlays ensures enhanced longevity and a more resilient surface, ideal for high-wear applications.

Choosing the Right Method for Your Product

Platinum inlay offers superior durability and a more pronounced, long-lasting finish due to its deep integration into the base material, making it ideal for high-end jewelry and precision instruments that require exceptional wear resistance. Platinum coating provides a cost-effective alternative with a sleek, reflective surface suitable for decorative items and electronics where extensive durability is not critical. Selecting between inlay and coating depends on the product's functional requirements, budget constraints, and desired aesthetic longevity.

Environmental Impact and Sustainability

Platinum inlays offer superior durability and longevity compared to platinum coatings, reducing the frequency of replacement and minimizing resource consumption. While platinum coatings require less raw material initially, they often necessitate reapplication or replacement, generating additional waste and environmental burden. The mining and refining of platinum have significant ecological impacts; choosing inlays helps optimize material use and promotes sustainability through enhanced product lifespan.

Platinum Inlay vs Platinum Coating Infographic

materialdif.com

materialdif.com