Cold working platinum enhances its hardness and strength through deformation at room temperature, making it ideal for detailed jewelry designs requiring precision. Hot working platinum involves heating the metal to high temperatures, allowing greater malleability and reducing the risk of cracking during shaping or forging. Choosing between cold and hot working depends on the desired balance of durability, detail, and ease of fabrication in platinum craftsmanship.

Table of Comparison

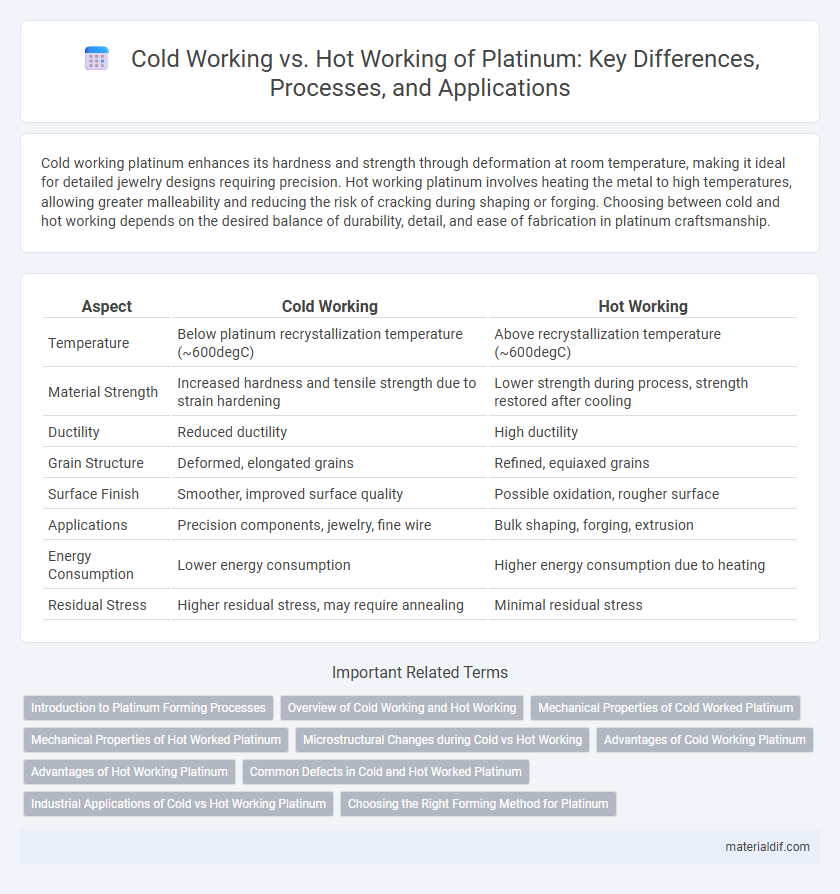

| Aspect | Cold Working | Hot Working |

|---|---|---|

| Temperature | Below platinum recrystallization temperature (~600degC) | Above recrystallization temperature (~600degC) |

| Material Strength | Increased hardness and tensile strength due to strain hardening | Lower strength during process, strength restored after cooling |

| Ductility | Reduced ductility | High ductility |

| Grain Structure | Deformed, elongated grains | Refined, equiaxed grains |

| Surface Finish | Smoother, improved surface quality | Possible oxidation, rougher surface |

| Applications | Precision components, jewelry, fine wire | Bulk shaping, forging, extrusion |

| Energy Consumption | Lower energy consumption | Higher energy consumption due to heating |

| Residual Stress | Higher residual stress, may require annealing | Minimal residual stress |

Introduction to Platinum Forming Processes

Platinum forming processes involve cold working and hot working techniques, each affecting the metal's microstructure and mechanical properties. Cold working enhances strength and hardness through strain hardening but reduces ductility, making it ideal for precision shaping and fine detailing. Hot working, performed above platinum's recrystallization temperature, provides greater plasticity and refines grain structure, allowing significant deformation without cracking.

Overview of Cold Working and Hot Working

Cold working platinum involves deforming the metal at room temperature, enhancing its strength and hardness through strain hardening while maintaining excellent surface finish and dimensional accuracy. Hot working platinum takes place above its recrystallization temperature, allowing for significant shape changes with reduced risk of cracking and improved ductility, though it may lead to oxidation and scale formation. Both methods influence platinum's mechanical properties and microstructure, with the choice depending on the desired balance between workability and final material characteristics.

Mechanical Properties of Cold Worked Platinum

Cold working platinum significantly enhances its mechanical properties by increasing hardness and tensile strength through strain hardening without altering its corrosion resistance. This process refines the grain structure, resulting in improved wear resistance and dimensional stability critical for precision applications. Cold worked platinum maintains excellent ductility compared to hot worked materials, making it ideal for fine jewelry and high-performance electrical contacts.

Mechanical Properties of Hot Worked Platinum

Hot worked platinum exhibits enhanced ductility and toughness compared to cold worked variants, as elevated temperatures promote dynamic recrystallization and grain refinement. This process reduces internal stresses and dislocation density, resulting in improved tensile strength and resistance to fracture. Mechanical properties such as yield strength and elongation are optimized through controlled hot working parameters, making platinum suitable for high-performance applications requiring both strength and malleability.

Microstructural Changes during Cold vs Hot Working

Cold working of platinum induces strain hardening and increases dislocation density, resulting in refined grain structures and enhanced mechanical strength but reduced ductility. Hot working, performed above platinum's recrystallization temperature (around 600-700degC), promotes dynamic recovery and recrystallization, leading to grain growth, reduced dislocation density, and improved ductility. These microstructural changes significantly influence the metal's performance in applications requiring high corrosion resistance and electrical conductivity.

Advantages of Cold Working Platinum

Cold working platinum enhances its mechanical strength and hardness through strain hardening while maintaining precise dimensional tolerances. This process improves surface finish quality and eliminates the risk of grain growth or oxidation common in hot working. Consequently, cold working is preferred for applications requiring high durability and corrosion resistance without altering the metal's inherent purity.

Advantages of Hot Working Platinum

Hot working platinum improves its ductility and refines grain structure, leading to enhanced mechanical properties and better performance under stress. This process reduces the risk of cracking and internal defects, ensuring superior durability in finished products. Elevated temperatures also facilitate easier shaping and forming, making hot working ideal for complex platinum components.

Common Defects in Cold and Hot Worked Platinum

Cold working platinum often leads to defects such as strain hardening, micro-cracks, and residual stresses, which reduce ductility and increase brittleness. Hot working allows for recrystallization, minimizing defects like porosity and cracking, but improper temperature control can cause grain growth and surface oxidation. Understanding these common defects is essential for optimizing platinum processing in jewelry and industrial applications.

Industrial Applications of Cold vs Hot Working Platinum

Cold working platinum enhances surface hardness and dimensional accuracy, making it ideal for precision components in electronics and jewelry manufacturing. Hot working platinum, performed at temperatures above 1000degC, improves ductility and grain structure, suited for large-scale industrial applications such as catalyst substrates and laboratory equipment. Choosing between cold and hot working depends on the required mechanical properties and production scale in platinum industrial processes.

Choosing the Right Forming Method for Platinum

Choosing the right forming method for platinum depends largely on its unique thermal and mechanical properties. Cold working enhances strength and hardness through strain hardening but increases brittleness, making it suitable for smaller, precise components. Hot working, performed above 900degC, improves ductility and reduces internal stresses, ideal for large or complex shapes requiring significant deformation without cracking.

Cold Working vs Hot Working (Platinum) Infographic

materialdif.com

materialdif.com