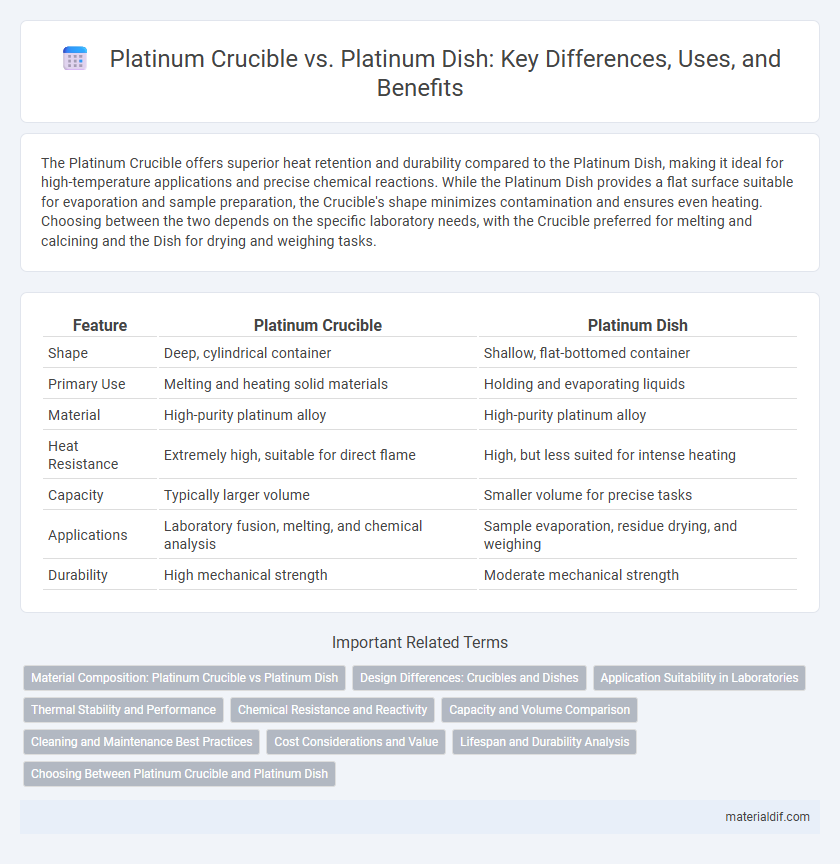

The Platinum Crucible offers superior heat retention and durability compared to the Platinum Dish, making it ideal for high-temperature applications and precise chemical reactions. While the Platinum Dish provides a flat surface suitable for evaporation and sample preparation, the Crucible's shape minimizes contamination and ensures even heating. Choosing between the two depends on the specific laboratory needs, with the Crucible preferred for melting and calcining and the Dish for drying and weighing tasks.

Table of Comparison

| Feature | Platinum Crucible | Platinum Dish |

|---|---|---|

| Shape | Deep, cylindrical container | Shallow, flat-bottomed container |

| Primary Use | Melting and heating solid materials | Holding and evaporating liquids |

| Material | High-purity platinum alloy | High-purity platinum alloy |

| Heat Resistance | Extremely high, suitable for direct flame | High, but less suited for intense heating |

| Capacity | Typically larger volume | Smaller volume for precise tasks |

| Applications | Laboratory fusion, melting, and chemical analysis | Sample evaporation, residue drying, and weighing |

| Durability | High mechanical strength | Moderate mechanical strength |

Material Composition: Platinum Crucible vs Platinum Dish

Platinum crucibles and platinum dishes are both made from high-purity platinum, typically 95-99.9% pure, ensuring excellent resistance to high temperatures and chemical corrosion. The material composition of a platinum crucible is often designed to withstand intense thermal cycling and mechanical stress, featuring slightly thicker walls compared to platinum dishes. Platinum dishes generally have thinner walls and a more uniform surface to facilitate even heat distribution and ease of sample handling during laboratory procedures.

Design Differences: Crucibles and Dishes

Platinum crucibles feature a deep, cylindrical shape with high walls optimized for containing and melting materials at extreme temperatures, while platinum dishes have a shallow, wide design suitable for evaporating liquids and holding samples during analysis. The crucible's taller structure provides greater volume and thermal stability, essential for high-temperature reactions, whereas the dish's broad surface area facilitates faster evaporation and easier access to the contents. Both are made from high-purity platinum to withstand corrosive environments and rapid temperature changes without contamination.

Application Suitability in Laboratories

Platinum crucibles are highly resistant to high temperatures and chemical corrosion, making them ideal for melting, calcining, and chemical reactions requiring intense heat in laboratories. Platinum dishes, while also durable and chemically inert, are better suited for evaporation, drying, and heating small samples due to their shallow design and ease of handling. The choice between a platinum crucible and dish depends on the laboratory application, with crucibles preferred for processes involving sustained high heat and dishes favored for sample preparation and analysis.

Thermal Stability and Performance

Platinum crucibles exhibit superior thermal stability compared to platinum dishes, with the ability to withstand repeated high-temperature cycles without deformation or contamination, making them ideal for precision laboratory applications. The design of platinum crucibles ensures even heat distribution, enhancing performance in processes like ashing and melting, whereas platinum dishes, while useful for surface reactions, offer less structural integrity under thermal stress. For applications demanding rigorous thermal resistance and consistent material purity, platinum crucibles provide a more reliable solution than platinum dishes.

Chemical Resistance and Reactivity

A platinum crucible offers superior chemical resistance and high-temperature stability, making it ideal for withstanding aggressive acids and strong oxidizing environments without corroding. In contrast, a platinum dish, while still chemically inert and resistant to many reagents, typically serves better for evaporating or drying applications due to its broader surface area but slightly lower resistance to mechanical stress. Both platinum crucibles and dishes excel in minimizing reactivity, but crucibles provide enhanced durability under harsh chemical reactions.

Capacity and Volume Comparison

A platinum crucible typically offers a higher capacity than a platinum dish, designed to withstand extreme temperatures and facilitate reactions requiring larger volumes. Crucibles commonly range from 5 mL to over 100 mL, while platinum dishes usually provide shallower volumes, typically between 10 mL and 50 mL. The deeper structure of crucibles enables greater volume containment, making them suitable for high-capacity laboratory applications compared to the flatter, lower-capacity platinum dishes.

Cleaning and Maintenance Best Practices

Platinum crucibles require meticulous cleaning to prevent contamination, typically using aqua regia or specialized platinum cleaning solutions followed by thorough rinsing and drying to maintain their high-temperature resistance and purity. Platinum dishes are easier to maintain, often cleaned with mild detergents and non-abrasive sponges, but still need careful handling to avoid surface scratches that can affect their chemical stability. Proper cleaning and maintenance extend the lifespan of both platinum crucibles and dishes, preserving their exceptional durability and resistance to corrosion in laboratory settings.

Cost Considerations and Value

A platinum crucible typically costs more than a platinum dish due to its thicker walls and higher material volume, which provide enhanced durability and resistance to thermal shock. Platinum dishes offer a more affordable option for applications requiring less mechanical stress, maintaining excellent chemical inertness and corrosion resistance. When evaluating cost considerations, the increased lifespan and robustness of platinum crucibles often justify their higher initial investment for intensive laboratory or industrial use.

Lifespan and Durability Analysis

Platinum crucibles typically offer superior lifespan and durability compared to platinum dishes due to their thicker walls and reinforced structure, making them highly resistant to thermal shock and chemical corrosion. The design of platinum crucibles allows for prolonged use in high-temperature environments, maintaining structural integrity over numerous heating and cooling cycles. In contrast, platinum dishes, while also resistant to corrosion, generally have thinner formations which can lead to quicker wear and a shorter functional lifespan under rigorous laboratory conditions.

Choosing Between Platinum Crucible and Platinum Dish

Selecting between a platinum crucible and a platinum dish depends on the specific laboratory application, with the crucible offering high-temperature resistance ideal for melting and chemical analysis. Platinum dishes provide a flat surface better suited for evaporations and small-scale reactions requiring uniform heat distribution. The decision hinges on the temperature tolerance, sample size, and the nature of the experimental procedure.

Platinum Crucible vs Platinum Dish Infographic

materialdif.com

materialdif.com