Platinum Iridium Alloy offers superior corrosion resistance and enhanced hardness compared to Platinum Cobalt Alloy, making it ideal for high-precision instruments and fine jewelry. While Platinum Cobalt Alloy provides excellent strength and durability, it tends to be more susceptible to oxidation over time. Choosing between these alloys depends on application requirements, with Platinum Iridium favored for longevity and Platinum Cobalt for cost-effectiveness.

Table of Comparison

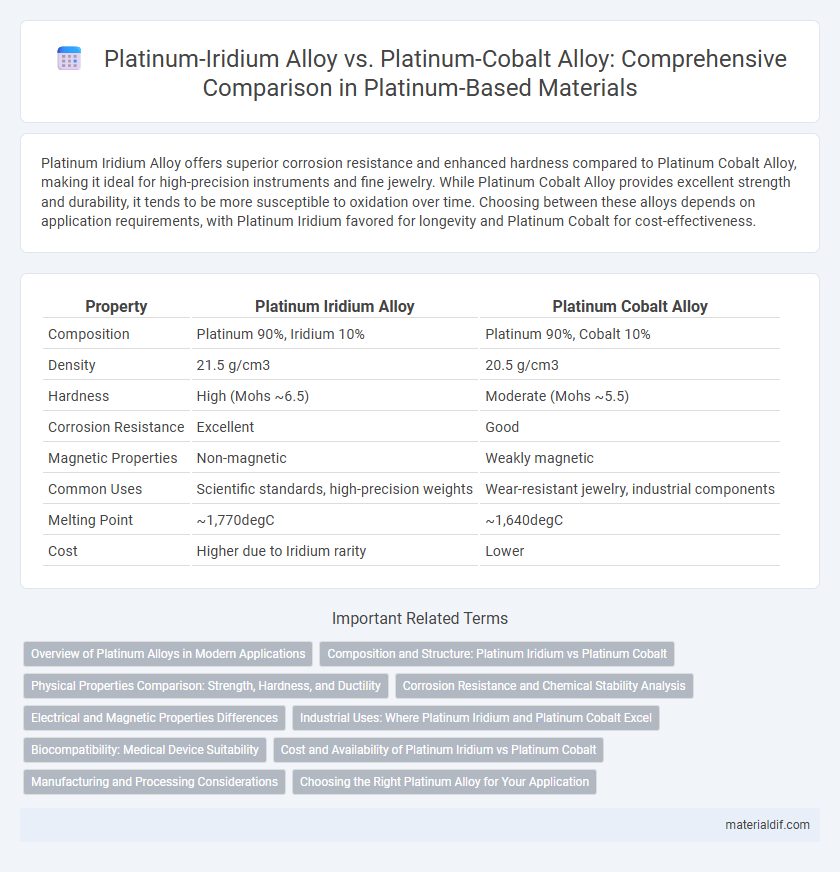

| Property | Platinum Iridium Alloy | Platinum Cobalt Alloy |

|---|---|---|

| Composition | Platinum 90%, Iridium 10% | Platinum 90%, Cobalt 10% |

| Density | 21.5 g/cm3 | 20.5 g/cm3 |

| Hardness | High (Mohs ~6.5) | Moderate (Mohs ~5.5) |

| Corrosion Resistance | Excellent | Good |

| Magnetic Properties | Non-magnetic | Weakly magnetic |

| Common Uses | Scientific standards, high-precision weights | Wear-resistant jewelry, industrial components |

| Melting Point | ~1,770degC | ~1,640degC |

| Cost | Higher due to Iridium rarity | Lower |

Overview of Platinum Alloys in Modern Applications

Platinum iridium alloy, known for its exceptional hardness and corrosion resistance, is widely used in precision instruments and electrical contacts, ensuring durability and stable performance. Platinum cobalt alloy offers excellent magnetic properties and high strength, making it ideal for scientific equipment and specialized industrial applications. Both alloys leverage platinum's inherent chemical stability, catering to advanced technologies where reliability and longevity are critical.

Composition and Structure: Platinum Iridium vs Platinum Cobalt

Platinum iridium alloy primarily consists of 90-95% platinum and 5-10% iridium, resulting in a dense, corrosion-resistant structure favored for scientific standards and high-precision instruments. In contrast, platinum cobalt alloy contains approximately 90-95% platinum and 5-10% cobalt, offering a slightly lower density and enhanced magnetic properties suitable for specialized industrial applications. The atomic structure of platinum iridium alloys exhibits greater hardness and stability due to iridium's higher atomic mass and strong bonding, while platinum cobalt alloys provide improved machinability and cost efficiency.

Physical Properties Comparison: Strength, Hardness, and Ductility

Platinum Iridium alloy exhibits higher hardness and strength compared to Platinum Cobalt alloy, making it more resistant to wear and deformation under stress. The increased hardness of Platinum Iridium enhances its durability in precision instruments, while its ductility remains sufficient for intricate shaping and forming processes. In contrast, Platinum Cobalt alloy offers greater ductility but lower strength, making it suitable for applications requiring more flexibility and ease of fabrication.

Corrosion Resistance and Chemical Stability Analysis

Platinum Iridium Alloy exhibits superior corrosion resistance compared to Platinum Cobalt Alloy due to the higher chemical inertness of iridium, which forms a robust passivation layer that prevents oxidation and degradation. Chemical stability tests show that Platinum Iridium alloys maintain their structural integrity under harsh acidic and oxidative environments better than Platinum Cobalt alloys, which are more prone to surface pitting and corrosion. Consequently, Platinum Iridium Alloy is preferred in applications demanding long-term durability and resistance to aggressive chemical exposure.

Electrical and Magnetic Properties Differences

Platinum iridium alloy exhibits superior corrosion resistance and electrical conductivity compared to platinum cobalt alloy, making it ideal for precision electrical contacts and standards. The magnetic susceptibility of platinum cobalt alloy is higher, resulting in more pronounced magnetic behavior, which can interfere with sensitive electromagnetic applications. These differences influence material selection in industries requiring stable electrical performance and minimal magnetic interference.

Industrial Uses: Where Platinum Iridium and Platinum Cobalt Excel

Platinum iridium alloy is highly valued in industrial applications requiring exceptional hardness, corrosion resistance, and electrical conductivity, making it ideal for precision instruments, electrical contacts, and fountain pen nibs. Platinum cobalt alloy excels in magnetic and biomedical uses due to its favorable magnetic properties and biocompatibility, often utilized in medical implants, magnetic sensors, and high-strength components. Each alloy's distinct chemical and physical traits define its superiority in specific technological and industrial sectors.

Biocompatibility: Medical Device Suitability

Platinum iridium alloy exhibits superior biocompatibility compared to platinum cobalt alloy, making it more suitable for long-term medical implants and devices due to its excellent corrosion resistance and minimal ion release. The inert nature of iridium reduces the risk of adverse tissue reactions, enhancing patient safety in cardiovascular stents, pacemaker leads, and neurostimulators. Platinum cobalt alloy, while durable, carries a higher potential for metal ion leaching, limiting its application in sensitive biological environments.

Cost and Availability of Platinum Iridium vs Platinum Cobalt

Platinum iridium alloy generally commands a higher price than platinum cobalt alloy due to the scarcity and high demand of iridium, a rare and expensive metal, whereas cobalt is more abundant and cost-effective. Availability of platinum iridium alloys can be limited because iridium's extraction and refinement processes are complex, leading to supply constraints. Platinum cobalt alloys benefit from broader availability and lower production costs, making them a more accessible choice for industrial applications.

Manufacturing and Processing Considerations

Platinum iridium alloy offers superior hardness and corrosion resistance, making it ideal for manufacturing precision instruments requiring durability under high-stress conditions. Platinum cobalt alloy provides enhanced magnetic properties and ease of machining, beneficial for specialized applications that demand exact dimensional control and magnetic responsiveness. Processing platinum iridium requires higher melting points and longer annealing cycles, while platinum cobalt allows for more straightforward casting and quicker heat treatments, optimizing production efficiency.

Choosing the Right Platinum Alloy for Your Application

Platinum iridium alloy offers superior hardness and corrosion resistance, making it ideal for precision instruments and high-durability applications, while platinum cobalt alloy provides enhanced strength and magnetic properties suited for specialized industrial uses. Selecting the right platinum alloy depends on the specific mechanical, chemical, and environmental requirements of your project, with iridium-rich alloys excelling in wear resistance and cobalt-infused variants favored for structural integrity under stress. Understanding the balance between durability and functionality in platinum alloys ensures optimal performance and longevity in applications ranging from medical devices to aerospace components.

Platinum Iridium Alloy vs Platinum Cobalt Alloy Infographic

materialdif.com

materialdif.com