Platinum casting involves melting the metal and pouring it into a mold, allowing for intricate designs and detailed shapes with high precision. Platinum forging, on the other hand, uses mechanical force to shape the metal, resulting in enhanced strength and durability due to the metal's refined grain structure. Choosing between casting and forging depends on whether design complexity or structural integrity is the priority for the platinum piece.

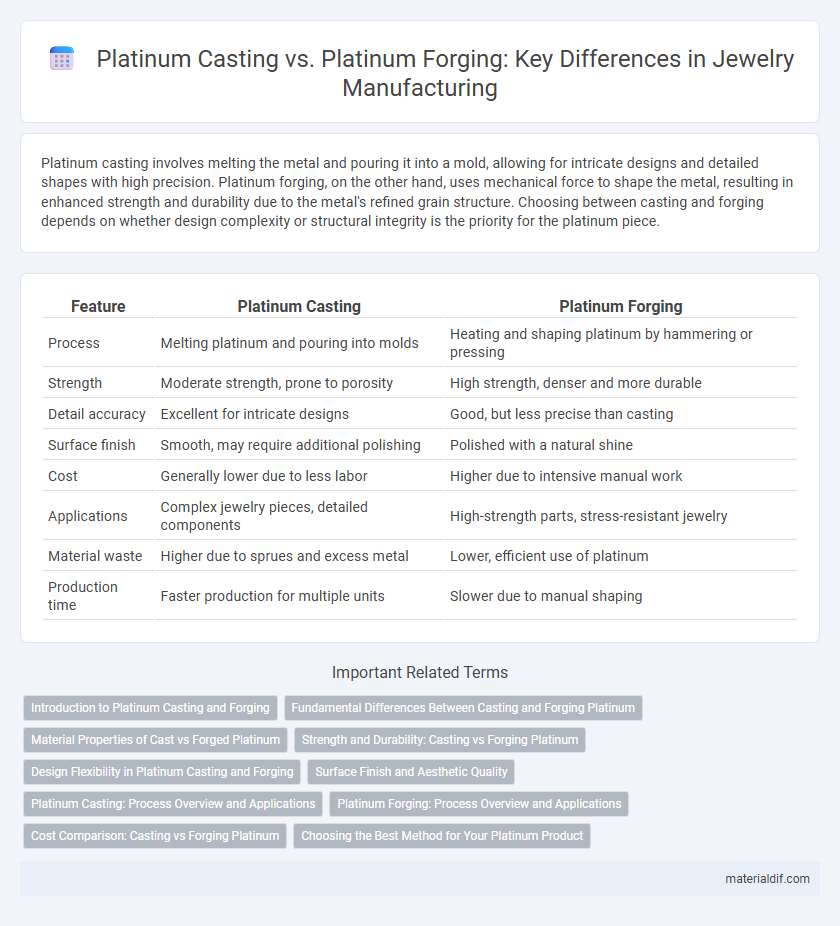

Table of Comparison

| Feature | Platinum Casting | Platinum Forging |

|---|---|---|

| Process | Melting platinum and pouring into molds | Heating and shaping platinum by hammering or pressing |

| Strength | Moderate strength, prone to porosity | High strength, denser and more durable |

| Detail accuracy | Excellent for intricate designs | Good, but less precise than casting |

| Surface finish | Smooth, may require additional polishing | Polished with a natural shine |

| Cost | Generally lower due to less labor | Higher due to intensive manual work |

| Applications | Complex jewelry pieces, detailed components | High-strength parts, stress-resistant jewelry |

| Material waste | Higher due to sprues and excess metal | Lower, efficient use of platinum |

| Production time | Faster production for multiple units | Slower due to manual shaping |

Introduction to Platinum Casting and Forging

Platinum casting involves melting the metal and pouring it into molds to create intricate, precise shapes ideal for jewelry and industrial components. Forging Platinum applies compressive forces to shape the metal, enhancing its strength and grain structure for durable, high-performance applications. Both processes are key in maximizing platinum's unique properties, with casting offering design flexibility and forging delivering superior mechanical integrity.

Fundamental Differences Between Casting and Forging Platinum

Platinum casting involves pouring molten platinum into a mold to create intricate designs with high detail and complexity, making it ideal for customized jewelry pieces. Platinum forging, on the other hand, uses compressive forces to shape solid platinum, resulting in denser, stronger, and more durable structures with enhanced grain flow. Fundamental differences between casting and forging platinum lie in the manufacturing process, mechanical properties, and the final product's strength and precision.

Material Properties of Cast vs Forged Platinum

Cast platinum typically exhibits a more uniform microstructure with excellent corrosion resistance and moderate tensile strength, making it ideal for intricate designs and detailed jewelry pieces. Forged platinum, on the other hand, has higher density and superior mechanical properties such as increased hardness, toughness, and tensile strength, resulting from the cold working process that refines its grain structure. The choice between cast and forged platinum significantly influences durability, weight, and finish quality, with forged platinum providing enhanced wear resistance compared to the more malleable cast counterparts.

Strength and Durability: Casting vs Forging Platinum

Platinum forging enhances strength and durability by aligning metal grains through hammering and pressing, resulting in a denser, more resilient structure ideal for high-stress applications. In contrast, platinum casting involves pouring molten metal into molds, which can create minor porosity and lacks the grain alignment found in forged pieces, making cast platinum slightly less durable under mechanical strain. Forged platinum typically exhibits superior tensile strength and resistance to wear compared to cast platinum, making it the preferred choice for jewelry and components requiring long-lasting performance.

Design Flexibility in Platinum Casting and Forging

Platinum casting offers superior design flexibility by allowing intricate shapes and complex details to be created with ease, making it ideal for custom and artistic jewelry pieces. In contrast, platinum forging results in stronger, denser metal but limits design complexity due to the deformation process involved, best suited for simpler and more robust designs. The choice between casting and forging directly impacts the final piece's aesthetic intricacy and structural durability in platinum jewelry manufacturing.

Surface Finish and Aesthetic Quality

Platinum casting offers a smooth surface finish ideal for intricate designs but may require additional polishing to enhance aesthetic quality. Platinum forging, by contrast, produces a denser metal with superior strength and a naturally lustrous surface, resulting in higher overall visual appeal. The choice between casting and forging directly impacts the platinum jewelry's durability and brilliance, influencing final user satisfaction.

Platinum Casting: Process Overview and Applications

Platinum casting involves melting platinum at high temperatures and pouring the molten metal into precision molds to create complex shapes with fine details, making it ideal for intricate jewelry designs and dental restorations. This process allows for excellent material utilization and customization, enabling the production of both small-scale art pieces and large industrial components. Platinum casting is favored for its ability to deliver high-quality, durable products with smooth finishes and minimal waste.

Platinum Forging: Process Overview and Applications

Platinum forging involves shaping the metal under high pressure and temperature to enhance its strength, density, and grain structure, resulting in superior durability and resistance to wear compared to casting. This process typically includes heating platinum ingots followed by hammering or pressing, which refines the metal's microstructure and reduces porosity. Forged platinum is widely used in high-performance industrial components, precision jewelry, and surgical instruments due to its enhanced mechanical properties and reliability.

Cost Comparison: Casting vs Forging Platinum

Platinum casting generally incurs lower upfront tooling costs compared to forging, making it more cost-effective for small to medium production runs. Forging platinum involves higher energy consumption and specialized labor, leading to increased overall expenses, especially for complex designs. For large-scale or high-strength applications, the investment in forging may justify the cost through superior mechanical properties and reduced material waste.

Choosing the Best Method for Your Platinum Product

Platinum casting offers intricate design possibilities and cost efficiency for complex jewelry pieces, while platinum forging ensures superior strength and durability ideal for high-stress applications. Selecting the best method depends on the product's required detail, mechanical properties, and production volume. Understanding these factors allows manufacturers to optimize quality and performance tailored to specific platinum items.

Platinum Casting vs Platinum Forging Infographic

materialdif.com

materialdif.com