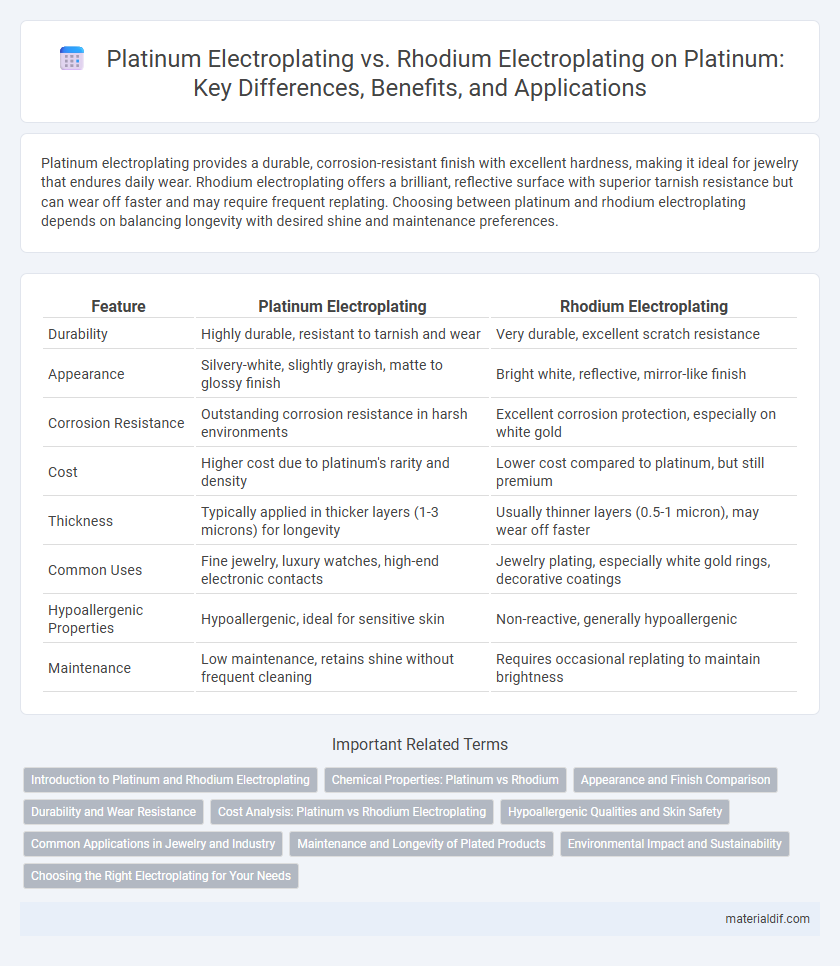

Platinum electroplating provides a durable, corrosion-resistant finish with excellent hardness, making it ideal for jewelry that endures daily wear. Rhodium electroplating offers a brilliant, reflective surface with superior tarnish resistance but can wear off faster and may require frequent replating. Choosing between platinum and rhodium electroplating depends on balancing longevity with desired shine and maintenance preferences.

Table of Comparison

| Feature | Platinum Electroplating | Rhodium Electroplating |

|---|---|---|

| Durability | Highly durable, resistant to tarnish and wear | Very durable, excellent scratch resistance |

| Appearance | Silvery-white, slightly grayish, matte to glossy finish | Bright white, reflective, mirror-like finish |

| Corrosion Resistance | Outstanding corrosion resistance in harsh environments | Excellent corrosion protection, especially on white gold |

| Cost | Higher cost due to platinum's rarity and density | Lower cost compared to platinum, but still premium |

| Thickness | Typically applied in thicker layers (1-3 microns) for longevity | Usually thinner layers (0.5-1 micron), may wear off faster |

| Common Uses | Fine jewelry, luxury watches, high-end electronic contacts | Jewelry plating, especially white gold rings, decorative coatings |

| Hypoallergenic Properties | Hypoallergenic, ideal for sensitive skin | Non-reactive, generally hypoallergenic |

| Maintenance | Low maintenance, retains shine without frequent cleaning | Requires occasional replating to maintain brightness |

Introduction to Platinum and Rhodium Electroplating

Platinum electroplating involves depositing a thin layer of platinum onto a metal surface to enhance corrosion resistance, durability, and aesthetic appeal, making it ideal for fine jewelry and industrial applications. Rhodium electroplating provides a reflective, bright white finish with exceptional hardness and tarnish resistance, often used to improve the appearance and longevity of white gold and silver jewelry. Both processes utilize electrochemical techniques but differ in metal properties, cost, and typical use cases within the luxury and manufacturing sectors.

Chemical Properties: Platinum vs Rhodium

Platinum and rhodium exhibit distinct chemical properties that influence their electroplating applications; platinum is highly resistant to corrosion and oxidation due to its stable electron configuration, making it ideal for long-lasting coatings. Rhodium, a member of the platinum group metals, offers superior hardness and reflectivity, with exceptional resistance to tarnishing caused by sulfur compounds and acids. These chemical differences impact their suitability for protective and decorative electroplating, with platinum preferred for durability and rhodium favored for enhanced brightness and scratch resistance.

Appearance and Finish Comparison

Platinum electroplating offers a warm silver-white luster with excellent durability, maintaining a smooth, polished finish that resists tarnish over time. Rhodium electroplating provides a brighter, more reflective white sheen with superior scratch resistance and a slightly harder surface, enhancing the jewelry's shine and longevity. While platinum plating emphasizes a subtle, elegant glow, rhodium plating delivers a striking, mirror-like finish favored for contemporary designs.

Durability and Wear Resistance

Platinum electroplating offers exceptional durability and superior wear resistance due to its dense and corrosion-resistant properties, making it ideal for high-wear jewelry and industrial applications. Rhodium electroplating provides a bright, reflective surface but is generally softer and more prone to wear, requiring more frequent re-plating to maintain its appearance. Choosing platinum electroplating enhances long-term longevity, especially in environments subject to abrasion and chemical exposure.

Cost Analysis: Platinum vs Rhodium Electroplating

Platinum electroplating typically incurs higher costs than rhodium electroplating due to the metal's greater market price and the complexity of its plating process. Rhodium plating offers a more affordable alternative with exceptional brightness and corrosion resistance, though its thinner layer may wear faster over time. Cost analysis favors rhodium for budget-conscious applications, while platinum plating is preferred for its durability and prestigious appeal despite the premium expense.

Hypoallergenic Qualities and Skin Safety

Platinum electroplating offers superior hypoallergenic qualities compared to rhodium electroplating due to its inert nature, minimizing the risk of skin irritation and allergic reactions. While rhodium plating is often used for its bright finish, it may cause sensitivity issues in individuals with metal allergies, particularly when the plating wears off and exposes base metals. Platinum's stable and non-reactive surface makes it a safer choice for those with sensitive skin seeking durable, hypoallergenic jewelry finishes.

Common Applications in Jewelry and Industry

Platinum electroplating is frequently used in high-end jewelry to enhance durability, corrosion resistance, and provide a luxurious white finish, often applied to watches, rings, and fine jewelry pieces. Rhodium electroplating is prized in jewelry for its brilliant, reflective white surface and scratch-resistance, commonly used on white gold and sterling silver to prevent tarnishing and improve appearance. In industrial applications, platinum plating is favored for its chemical stability and catalytic properties in automotive and electronic components, while rhodium plating is utilized for its hardness and electrical conductivity in connectors and optical instruments.

Maintenance and Longevity of Plated Products

Platinum electroplating offers superior durability and corrosion resistance, making it ideal for maintaining the original luster of jewelry and industrial components over extended periods. In contrast, rhodium electroplating provides a bright, reflective finish but tends to wear down faster, requiring more frequent re-plating to preserve its appearance. The long-term maintenance cost of platinum-plated items is typically lower due to its enhanced longevity and resistance to tarnishing and abrasion.

Environmental Impact and Sustainability

Platinum electroplating offers a less toxic alternative to rhodium plating, as platinum is more chemically stable and produces fewer hazardous waste byproducts during the plating process. While rhodium plating provides superior hardness and reflectivity, its extraction and electroplating involve more environmentally harmful chemicals and higher energy consumption. Choosing platinum electroplating supports sustainability through reduced ecological footprint and promotes safer waste management in jewelry and industrial applications.

Choosing the Right Electroplating for Your Needs

Platinum electroplating offers exceptional durability and resistance to tarnishing, making it ideal for high-wear jewelry and industrial applications requiring longevity. Rhodium electroplating provides a brilliant white finish with excellent scratch resistance, commonly used to enhance the appearance of white gold and silver pieces. Selecting between platinum and rhodium electroplating depends on whether the priority is on long-lasting protection or achieving a bright, reflective surface for aesthetic enhancement.

Platinum Electroplating vs Rhodium Electroplating Infographic

materialdif.com

materialdif.com