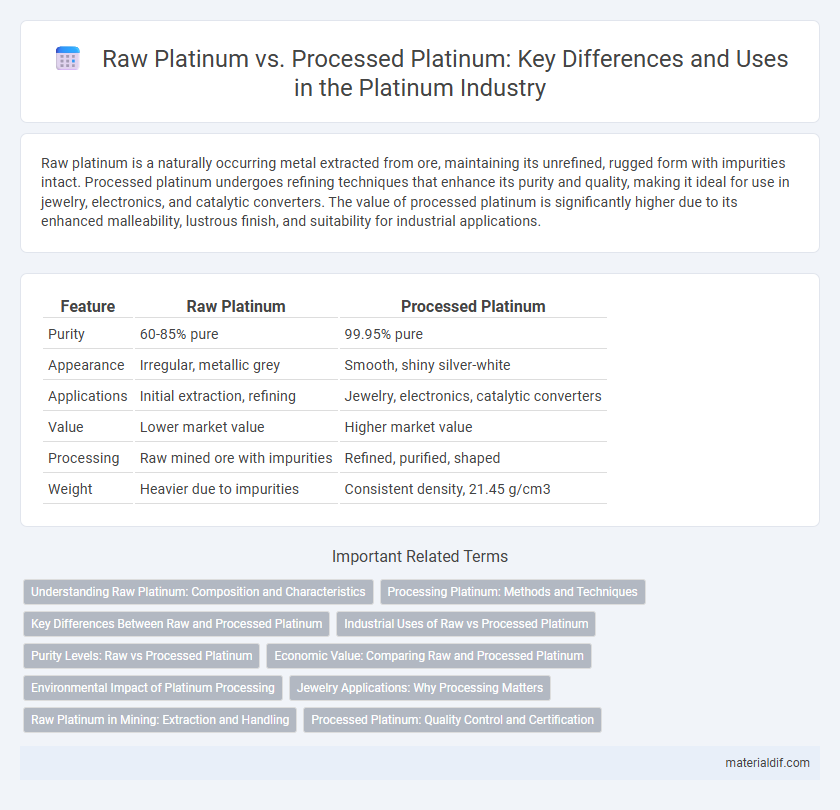

Raw platinum is a naturally occurring metal extracted from ore, maintaining its unrefined, rugged form with impurities intact. Processed platinum undergoes refining techniques that enhance its purity and quality, making it ideal for use in jewelry, electronics, and catalytic converters. The value of processed platinum is significantly higher due to its enhanced malleability, lustrous finish, and suitability for industrial applications.

Table of Comparison

| Feature | Raw Platinum | Processed Platinum |

|---|---|---|

| Purity | 60-85% pure | 99.95% pure |

| Appearance | Irregular, metallic grey | Smooth, shiny silver-white |

| Applications | Initial extraction, refining | Jewelry, electronics, catalytic converters |

| Value | Lower market value | Higher market value |

| Processing | Raw mined ore with impurities | Refined, purified, shaped |

| Weight | Heavier due to impurities | Consistent density, 21.45 g/cm3 |

Understanding Raw Platinum: Composition and Characteristics

Raw platinum consists primarily of platinum group metals, including palladium, rhodium, and iridium, embedded within mineral ores such as sperrylite and cooperite. Its composition varies depending on the geological source, often containing impurities like iron, nickel, and copper, which influence its physical properties and extraction complexity. Understanding raw platinum's natural alloy state and mineral matrix is essential for optimizing refining techniques that yield high-purity platinum suitable for industrial and jewelry applications.

Processing Platinum: Methods and Techniques

Processing platinum involves a series of specialized methods including smelting, refining, and chemical treatment to extract pure metal from raw ore. Techniques such as aqua regia refining, electrorefining, and solvent extraction are employed to remove impurities and achieve high purity levels exceeding 99.95%. The use of high-temperature furnaces and state-of-the-art recovery systems ensures efficient separation of platinum from other metals like palladium, rhodium, and iridium during the refining process.

Key Differences Between Raw and Processed Platinum

Raw platinum is a naturally occurring precious metal found in mineral deposits, characterized by its unrefined state with impurities and a dull, irregular surface. Processed platinum undergoes refining techniques such as smelting and electrolysis, resulting in a highly pure, malleable, and shiny metal suitable for industrial applications and jewelry. The key differences lie in purity levels, physical appearance, and usability, with processed platinum offering enhanced consistency and value for manufacturing and investment purposes.

Industrial Uses of Raw vs Processed Platinum

Raw platinum, rich in impurities, is primarily utilized in industries where its natural properties suffice, such as catalytic converters in automotive manufacturing and certain chemical processing applications. Processed platinum, refined to high purity levels, is essential for precision industries like electronics, medical devices, and high-performance aerospace components where durability and conductivity are critical. The distinction between raw and processed platinum directly influences its industrial application, optimizing performance and cost-efficiency based on purity requirements.

Purity Levels: Raw vs Processed Platinum

Raw platinum typically contains impurities such as iron, nickel, and copper, resulting in purity levels ranging from 70% to 90%. Processed platinum undergoes refining methods like electrolysis and chemical treatment, achieving purities of 99.5% to 99.99%, essential for industrial and jewelry applications. High purity levels in processed platinum ensure enhanced durability, corrosion resistance, and conductivity critical for catalytic converters, electronics, and fine jewelry.

Economic Value: Comparing Raw and Processed Platinum

Raw platinum carries significant intrinsic value due to its rarity and purity but often sells below market price because it requires refinement. Processed platinum, refined to a higher purity and crafted into usable forms, commands a premium price in industrial, jewelry, and investment markets. The economic value of processed platinum is amplified by added labor, advanced technologies, and market demand for certified purity.

Environmental Impact of Platinum Processing

Raw platinum extraction involves mining processes that generate significant environmental disturbances such as habitat destruction, soil erosion, and energy-intensive operations, leading to carbon emissions and water pollution. Processed platinum, on the other hand, undergoes refining techniques including smelting and chemical treatments that emit hazardous substances like sulfur dioxide and heavy metals into the air and water, posing risks to ecosystems and human health. Sustainable practices in platinum processing aim to reduce these environmental impacts by recycling platinum, improving energy efficiency, and implementing cleaner technologies.

Jewelry Applications: Why Processing Matters

Raw platinum contains impurities and irregular textures that reduce its suitability for fine jewelry, while processed platinum boasts enhanced purity and malleability essential for intricate designs. The refining process removes contaminants, resulting in a metal that offers superior luster, durability, and hypoallergenic properties valued in high-end jewelry pieces. Precise alloying during processing also improves platinum's hardness and tarnish resistance, making it ideal for crafting long-lasting, elegant jewelry.

Raw Platinum in Mining: Extraction and Handling

Raw platinum is extracted from ultramafic and mafic igneous rocks through deep mining operations, often involving both underground and open-pit techniques. The raw ore contains platinum along with other platinum group metals (PGMs), requiring careful handling to preserve its value and minimize loss during transport to smelting facilities. Effective extraction processes focus on maximizing yield from platinum sulfide ores while managing environmental impacts and operational safety.

Processed Platinum: Quality Control and Certification

Processed platinum undergoes rigorous quality control measures including purity testing through techniques such as X-ray fluorescence (XRF) and inductively coupled plasma mass spectrometry (ICP-MS) to ensure compliance with international standards. Certification from reputable organizations like the International Platinum Group Metals Association (IPA) guarantees the authenticity and grade of the refined metal, providing traceability and assurance for industrial and jewelry applications. High-quality processed platinum exhibits consistent physical and chemical properties essential for advanced uses in catalytic converters, electronics, and fine jewelry manufacturing.

Raw Platinum vs Processed Platinum Infographic

materialdif.com

materialdif.com