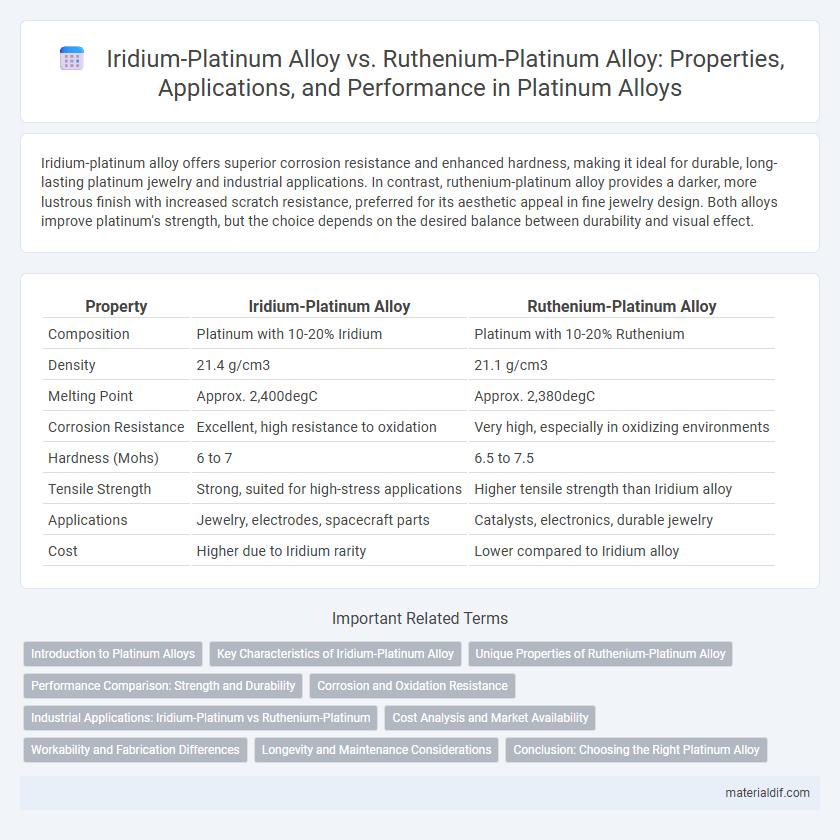

Iridium-platinum alloy offers superior corrosion resistance and enhanced hardness, making it ideal for durable, long-lasting platinum jewelry and industrial applications. In contrast, ruthenium-platinum alloy provides a darker, more lustrous finish with increased scratch resistance, preferred for its aesthetic appeal in fine jewelry design. Both alloys improve platinum's strength, but the choice depends on the desired balance between durability and visual effect.

Table of Comparison

| Property | Iridium-Platinum Alloy | Ruthenium-Platinum Alloy |

|---|---|---|

| Composition | Platinum with 10-20% Iridium | Platinum with 10-20% Ruthenium |

| Density | 21.4 g/cm3 | 21.1 g/cm3 |

| Melting Point | Approx. 2,400degC | Approx. 2,380degC |

| Corrosion Resistance | Excellent, high resistance to oxidation | Very high, especially in oxidizing environments |

| Hardness (Mohs) | 6 to 7 | 6.5 to 7.5 |

| Tensile Strength | Strong, suited for high-stress applications | Higher tensile strength than Iridium alloy |

| Applications | Jewelry, electrodes, spacecraft parts | Catalysts, electronics, durable jewelry |

| Cost | Higher due to Iridium rarity | Lower compared to Iridium alloy |

Introduction to Platinum Alloys

Platinum alloys such as Iridium-Platinum and Ruthenium-Platinum are key materials in jewelry and industrial applications due to their enhanced durability and corrosion resistance. Iridium-Platinum alloys exhibit exceptional hardness and high melting points, making them ideal for high-stress environments. Ruthenium-Platinum alloys offer improved scratch resistance and luster retention, contributing to their popularity in fine jewelry and catalytic converters.

Key Characteristics of Iridium-Platinum Alloy

Iridium-Platinum alloy exhibits exceptional hardness and corrosion resistance, making it ideal for high-stress industrial applications. Its superior melting point and stabilization in extreme temperatures outperform Ruthenium-Platinum alloys, which are typically softer and less durable. The unique blend of iridium's brittleness and platinum's ductility results in a highly durable material favored in catalytic converters and aerospace components.

Unique Properties of Ruthenium-Platinum Alloy

Ruthenium-platinum alloy exhibits exceptional hardness and enhanced wear resistance compared to iridium-platinum alloy, making it ideal for applications requiring durable and scratch-resistant materials. This alloy also demonstrates superior corrosion resistance, particularly in acidic environments, thereby increasing longevity in harsh chemical conditions. Its unique catalytic properties enhance efficiency in hydrogenation reactions, distinguishing it from iridium-platinum alloys commonly used in electrical contacts and high-temperature environments.

Performance Comparison: Strength and Durability

Iridium-platinum alloys exhibit exceptional strength and superior corrosion resistance, making them ideal for high-stress applications in harsh environments. Ruthenium-platinum alloys offer increased hardness and wear resistance but generally fall short of iridium-platinum in overall tensile strength and long-term durability. Performance evaluations show iridium-platinum alloys maintain structural integrity better under extreme thermal and mechanical stress compared to ruthenium-platinum alloys.

Corrosion and Oxidation Resistance

Iridium-platinum alloys exhibit superior corrosion and oxidation resistance compared to ruthenium-platinum alloys, making them ideal for extreme chemical environments and high-temperature applications. The dense atomic structure of iridium enhances the alloy's impermeability to corrosive agents, while ruthenium-platinum alloys, though resistant, are more susceptible to surface oxidation under prolonged exposure. These properties are critical in industries such as automotive catalytic converters and chemical processing equipment, where durability against harsh conditions is paramount.

Industrial Applications: Iridium-Platinum vs Ruthenium-Platinum

Iridium-platinum alloys exhibit exceptional corrosion resistance and high-temperature stability, making them ideal for industrial applications such as electrical contacts, crucibles, and aerospace components. Ruthenium-platinum alloys offer enhanced hardness and wear resistance, which are advantageous in applications like catalytic converters, jewelry, and hard-wearing electrical contacts. Industrial demand favors iridium-platinum alloys for high-stress environments, whereas ruthenium-platinum alloys are preferred where durability and hardness are critical.

Cost Analysis and Market Availability

Iridium-platinum alloys typically exhibit higher cost due to the scarcity and extraction difficulty of iridium, which is among the rarest platinum group metals, driving market prices upward. Ruthenium-platinum alloys offer a more cost-effective alternative as ruthenium is more abundant and widely available, resulting in lower material expenses and improved market accessibility. Manufacturing industries favor ruthenium-platinum alloys for applications requiring robust catalytic properties without incurring the premium pricing associated with iridium-based mixtures.

Workability and Fabrication Differences

Iridium-platinum alloys exhibit superior workability due to iridium's excellent ductility and high melting point, allowing for easier fabrication and shaping in high-temperature applications. Ruthenium-platinum alloys offer enhanced hardness and wear resistance but require more advanced machining techniques because ruthenium's brittleness reduces malleability. The choice between these alloys depends on balancing the need for ease of fabrication against the desired mechanical properties and durability in specific industrial uses.

Longevity and Maintenance Considerations

Iridium-platinum alloys exhibit superior longevity due to iridium's exceptional hardness and corrosion resistance, resulting in minimal wear and reduced maintenance requirements over time. Ruthenium-platinum alloys offer good durability but tend to be softer, leading to increased surface wear and more frequent maintenance in high-stress applications. Selecting iridium-platinum alloys enhances long-term performance in jewelry and industrial uses where extended lifespan and low upkeep are critical.

Conclusion: Choosing the Right Platinum Alloy

Iridium-platinum alloys offer superior corrosion resistance and durability, making them ideal for high-stress industrial applications such as electronics and aerospace components. Ruthenium-platinum alloys excel in hardness and wear resistance, which suits them well for jewelry and precision instruments requiring a polished finish and long-lasting luster. Selecting the right platinum alloy depends on the specific application requirements, balancing factors like corrosion resistance, hardness, and aesthetic appeal.

Iridium-Platinum Alloy vs Ruthenium-Platinum Alloy Infographic

materialdif.com

materialdif.com