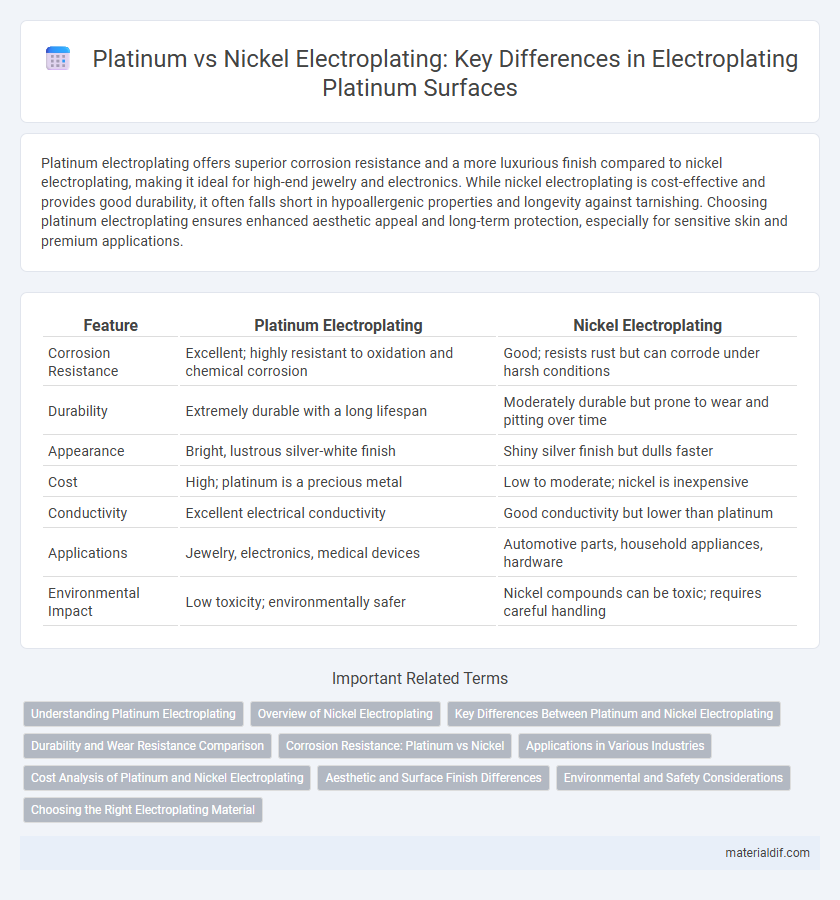

Platinum electroplating offers superior corrosion resistance and a more luxurious finish compared to nickel electroplating, making it ideal for high-end jewelry and electronics. While nickel electroplating is cost-effective and provides good durability, it often falls short in hypoallergenic properties and longevity against tarnishing. Choosing platinum electroplating ensures enhanced aesthetic appeal and long-term protection, especially for sensitive skin and premium applications.

Table of Comparison

| Feature | Platinum Electroplating | Nickel Electroplating |

|---|---|---|

| Corrosion Resistance | Excellent; highly resistant to oxidation and chemical corrosion | Good; resists rust but can corrode under harsh conditions |

| Durability | Extremely durable with a long lifespan | Moderately durable but prone to wear and pitting over time |

| Appearance | Bright, lustrous silver-white finish | Shiny silver finish but dulls faster |

| Cost | High; platinum is a precious metal | Low to moderate; nickel is inexpensive |

| Conductivity | Excellent electrical conductivity | Good conductivity but lower than platinum |

| Applications | Jewelry, electronics, medical devices | Automotive parts, household appliances, hardware |

| Environmental Impact | Low toxicity; environmentally safer | Nickel compounds can be toxic; requires careful handling |

Understanding Platinum Electroplating

Platinum electroplating offers superior corrosion resistance and excellent conductivity compared to nickel electroplating, making it ideal for high-performance applications in electronics and jewelry. The process involves depositing a thin layer of platinum onto a substrate through an electrolytic bath, providing enhanced durability and a luxurious finish. Unlike nickel plating, platinum electroplating resists oxidation and tarnishing, ensuring long-lasting aesthetic appeal and functional integrity.

Overview of Nickel Electroplating

Nickel electroplating involves depositing a thin layer of nickel onto a metal surface through an electrochemical process, enhancing corrosion resistance, hardness, and wear resistance. It is widely used in automotive, aerospace, and electronics industries due to its excellent adhesion and decorative finish. Nickel plating offers cost-effective protection but generally provides less corrosion resistance and brightness compared to platinum electroplating.

Key Differences Between Platinum and Nickel Electroplating

Platinum electroplating provides superior corrosion resistance and a more lustrous, durable finish compared to nickel electroplating, making it ideal for high-end jewelry and electronic components. Nickel electroplating, while cost-effective and offering moderate corrosion resistance, is prone to oxidation and can cause allergic reactions in sensitive users due to nickel ions. The key differences also include Platinum's higher melting point and biocompatibility, which enhance its application in medical devices, unlike nickel plating that is limited by lower thermal stability and potential toxicity concerns.

Durability and Wear Resistance Comparison

Platinum electroplating offers superior durability and wear resistance compared to nickel electroplating due to its higher hardness and corrosion resistance, making it ideal for high-wear applications. Platinum's resistance to tarnishing and oxidation ensures a longer-lasting, more resilient coating under extreme environmental conditions. Nickel plating, while cost-effective and providing decent wear resistance, tends to wear down faster and is more prone to corrosion, limiting its longevity in demanding uses.

Corrosion Resistance: Platinum vs Nickel

Platinum electroplating offers superior corrosion resistance compared to nickel electroplating due to its inert chemical properties and high resistance to oxidation and tarnishing. Nickel layers, although durable and cost-effective, are more prone to corrosion in harsh environments, especially when exposed to acidic or alkaline conditions. The enhanced durability of platinum coatings makes them ideal for applications requiring long-lasting protection against corrosion and maintaining aesthetic appeal.

Applications in Various Industries

Platinum electroplating is favored in medical and aerospace industries due to its exceptional corrosion resistance and biocompatibility, providing durable and non-reactive surfaces for implants and precision components. Nickel electroplating is widely used in automotive and electronics sectors for its excellent hardness, wear resistance, and cost-effectiveness, enhancing the durability of connectors and engine parts. The choice between platinum and nickel electroplating depends on specific application requirements, including environmental exposure, mechanical stress, and budget constraints.

Cost Analysis of Platinum and Nickel Electroplating

Platinum electroplating offers superior corrosion resistance and a luxurious finish but comes with significantly higher material costs compared to nickel electroplating, often exceeding nickel prices by up to 50 times per ounce. Nickel electroplating remains a cost-effective solution for industrial applications due to lower raw material and processing costs, despite its reduced durability in harsh environments. Evaluating total expenses involves considering both upfront plating costs and long-term maintenance savings, where platinum's longevity can offset initial investment in high-value or precision components.

Aesthetic and Surface Finish Differences

Platinum electroplating offers a superior aesthetic with a bright, lustrous white finish that resists tarnishing and maintains its brilliance over time, making it ideal for high-end jewelry and luxury items. Nickel electroplating provides a shinier and more reflective surface initially but tends to develop a dull patina and may show wear more quickly under frequent use. The inertness of platinum ensures a smooth, consistent surface finish that enhances durability and maintains an elegant appearance in contrast to nickel's more reactive and less stable coating.

Environmental and Safety Considerations

Platinum electroplating offers superior corrosion resistance and durability with significantly lower toxicity compared to nickel electroplating, which often involves hazardous chemicals like nickel salts that pose respiratory and skin sensitization risks. The waste generated from platinum plating processes is less toxic and easier to manage, reducing environmental impact and disposal costs. Platinum electroplating also eliminates the potential for allergic reactions common with nickel, making it a safer choice for consumer products and industrial applications.

Choosing the Right Electroplating Material

Platinum electroplating offers exceptional corrosion resistance and superior conductivity, making it ideal for high-performance and luxurious applications, while nickel electroplating provides excellent hardness and cost-effectiveness suitable for industrial and everyday use. Selecting the right electroplating material depends on factors such as environmental exposure, desired finish durability, and budget constraints. Platinum excels in environments requiring chemical stability and aesthetic appeal, whereas nickel is preferred for enhanced mechanical protection and affordability.

Platinum Electroplating vs Nickel Electroplating Infographic

materialdif.com

materialdif.com