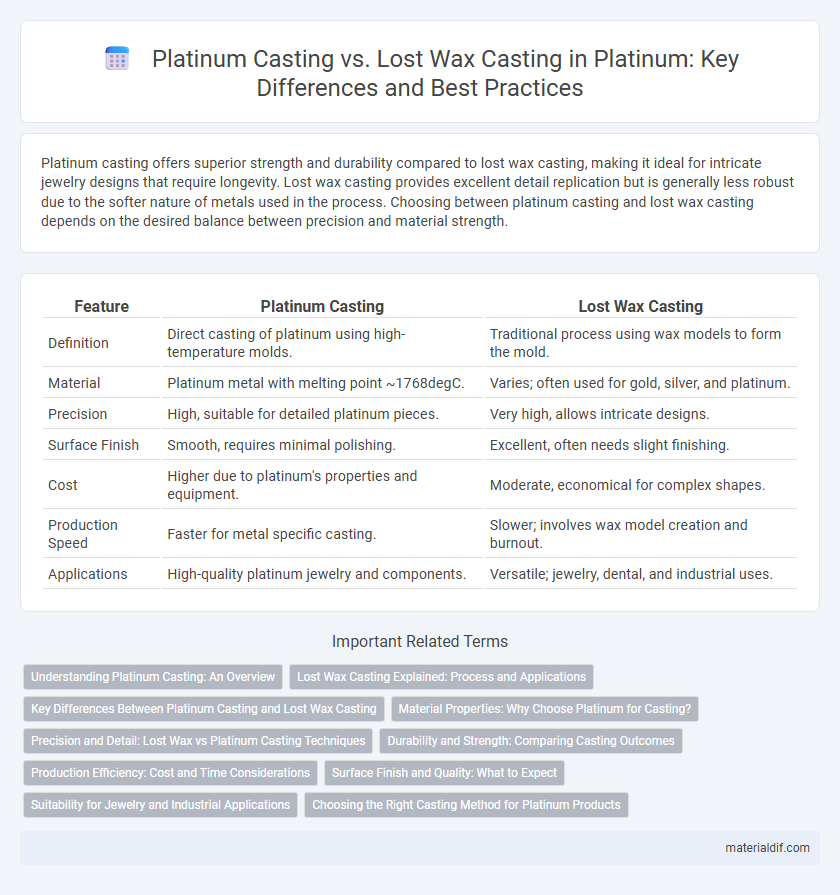

Platinum casting offers superior strength and durability compared to lost wax casting, making it ideal for intricate jewelry designs that require longevity. Lost wax casting provides excellent detail replication but is generally less robust due to the softer nature of metals used in the process. Choosing between platinum casting and lost wax casting depends on the desired balance between precision and material strength.

Table of Comparison

| Feature | Platinum Casting | Lost Wax Casting |

|---|---|---|

| Definition | Direct casting of platinum using high-temperature molds. | Traditional process using wax models to form the mold. |

| Material | Platinum metal with melting point ~1768degC. | Varies; often used for gold, silver, and platinum. |

| Precision | High, suitable for detailed platinum pieces. | Very high, allows intricate designs. |

| Surface Finish | Smooth, requires minimal polishing. | Excellent, often needs slight finishing. |

| Cost | Higher due to platinum's properties and equipment. | Moderate, economical for complex shapes. |

| Production Speed | Faster for metal specific casting. | Slower; involves wax model creation and burnout. |

| Applications | High-quality platinum jewelry and components. | Versatile; jewelry, dental, and industrial uses. |

Understanding Platinum Casting: An Overview

Platinum casting involves melting pure platinum and pouring it into molds to create durable, high-quality jewelry known for its strength and resistance to tarnish. Lost wax casting, a traditional technique often used for platinum, starts with a detailed wax model that is encased in a ceramic mold; once the wax is melted away, molten platinum is poured into the cavity, capturing intricate designs with precision. Understanding the advantages of platinum's high melting point and density is essential when selecting casting methods to ensure superior craftsmanship and longevity in finished pieces.

Lost Wax Casting Explained: Process and Applications

Lost wax casting, also known as investment casting, involves creating a detailed wax model that is coated with a ceramic material to form a mold; once hardened, the wax is melted away, leaving a cavity for molten platinum to be poured in. This process allows for high precision and intricate designs, making it ideal for producing fine platinum jewelry, dental restorations, and industrial components requiring exceptional detail and strength. Its ability to replicate complex geometries with minimal finishing enhances the value of platinum items by preserving the metal's natural luster and durability.

Key Differences Between Platinum Casting and Lost Wax Casting

Platinum casting specifically refers to the process of shaping platinum metal into desired forms, often using high temperatures to handle its unique melting point and density. Lost wax casting, a versatile technique, involves creating a wax model that is encased in a mold material; once the wax is melted away, molten metal is poured into the cavity to form the final piece. The key differences lie in the material focus and temperature requirements--platinum casting is a specialized method for platinum alloys, while lost wax casting is a broader technique applicable to various metals, emphasizing precision in capturing intricate details.

Material Properties: Why Choose Platinum for Casting?

Platinum's exceptional density and high melting point make it ideal for precision casting, ensuring durability and intricate detail retention in the final product. Its superior corrosion resistance and excellent malleability allow for complex designs without compromising structural integrity, unlike other metals. These material properties make platinum the preferred choice for lost wax casting, providing unmatched quality in fine jewelry and high-end industrial components.

Precision and Detail: Lost Wax vs Platinum Casting Techniques

Lost wax casting offers superior precision and intricate detail compared to traditional platinum casting methods, enabling fine, complex designs with smooth surfaces. The technique uses a wax model that is fully encased in a ceramic shell, allowing exact replication of even microscopic details when molten platinum is poured. Platinum casting typically delivers less detail due to the metal's high melting point and hardness, which can limit the reproduction of delicate features.

Durability and Strength: Comparing Casting Outcomes

Platinum casting typically offers superior durability and strength compared to lost wax casting due to its ability to withstand higher melting temperatures and resist deformation during cooling. Lost wax casting, while precise in detailing, may produce slightly less robust outcomes as the wax model can introduce minute imperfections affecting the metal's structural integrity. Metallurgical analysis shows that platinum castings often possess denser grain structures, resulting in enhanced hardness and greater resistance to wear and corrosion.

Production Efficiency: Cost and Time Considerations

Platinum casting offers high production efficiency with faster cycle times and lower material waste compared to lost wax casting, which involves multiple labor-intensive steps and extended processing periods. Lost wax casting, while ideal for intricate designs, incurs higher costs due to the detailed mold creation and longer curing times, impacting overall profitability. Selecting platinum casting streamlines the manufacturing process, reducing both time and expenses, thus enhancing cost-effectiveness in large-scale production.

Surface Finish and Quality: What to Expect

Platinum casting delivers a superior surface finish characterized by exceptional smoothness and high detail retention, making it ideal for fine jewelry and intricate designs. Lost wax casting allows for intricate mold creation but may require additional polishing to achieve the same level of surface perfection as direct platinum casting. Expect platinum casting to produce more consistent quality with fewer surface imperfections, whereas lost wax casting offers versatility at the expense of slightly increased post-processing.

Suitability for Jewelry and Industrial Applications

Platinum casting offers exceptional strength and durability, making it ideal for high-end jewelry that demands precision and intricate designs, while lost wax casting provides superior detail reproduction essential for delicate and custom pieces. Industrial applications benefit from platinum casting's resistance to corrosion and high melting point, whereas lost wax casting is preferred when complex geometries and fine tolerances are necessary. Choosing between these methods depends on the balance between desired detail, production volume, and material performance requirements.

Choosing the Right Casting Method for Platinum Products

Platinum casting requires precise temperature control and mold durability, which lost wax casting provides through its ability to capture intricate details and ensure high-quality surface finishes. Choosing lost wax casting for platinum products enhances dimensional accuracy and minimizes material waste, making it ideal for fine jewelry and complex designs. Traditional casting may be faster but lacks the refinement and precision required for platinum's density and melting point, impacting the final product's strength and appearance.

Platinum Casting vs Lost Wax Casting Infographic

materialdif.com

materialdif.com