Platinum electroplating involves coating a base metal with a thin layer of platinum through an electrochemical process, providing a durable and corrosion-resistant surface. In contrast, platinum cladding bonds a thicker layer of platinum mechanically to the base metal, resulting in a heavier and more robust finish that retains the look and feel of solid platinum. Electroplating is cost-effective and ideal for delicate designs, while cladding offers enhanced longevity and a premium appearance for high-end jewelry.

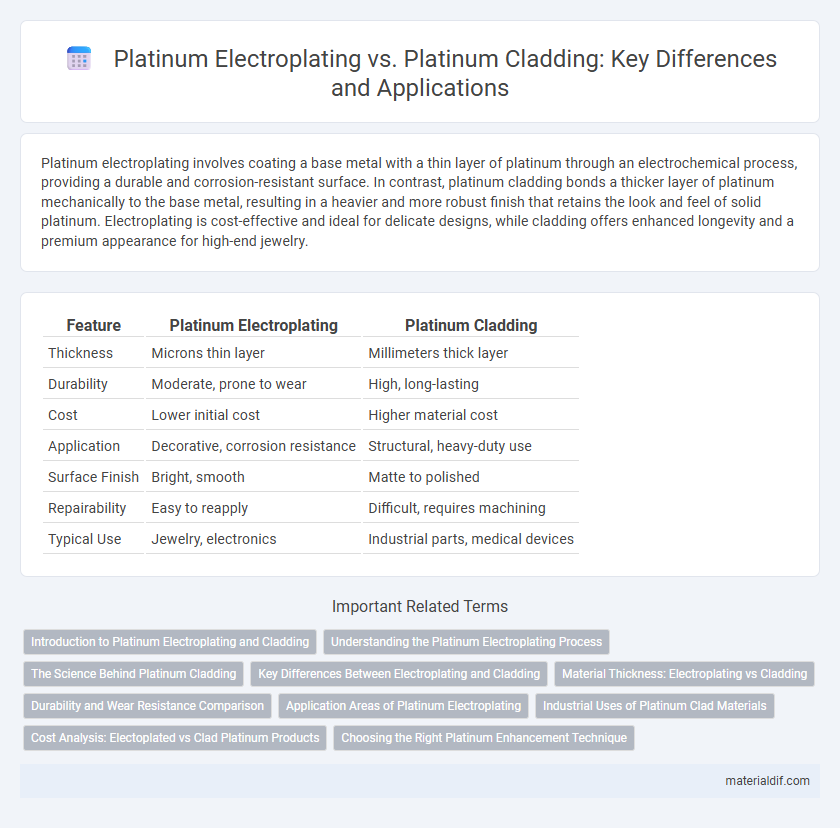

Table of Comparison

| Feature | Platinum Electroplating | Platinum Cladding |

|---|---|---|

| Thickness | Microns thin layer | Millimeters thick layer |

| Durability | Moderate, prone to wear | High, long-lasting |

| Cost | Lower initial cost | Higher material cost |

| Application | Decorative, corrosion resistance | Structural, heavy-duty use |

| Surface Finish | Bright, smooth | Matte to polished |

| Repairability | Easy to reapply | Difficult, requires machining |

| Typical Use | Jewelry, electronics | Industrial parts, medical devices |

Introduction to Platinum Electroplating and Cladding

Platinum electroplating involves depositing a thin layer of platinum onto a substrate through an electrochemical process, enhancing corrosion resistance and aesthetic appeal without significantly altering the base material's properties. Platinum cladding, in contrast, applies a thicker, mechanically bonded layer of platinum, providing greater durability and wear resistance ideal for high-stress applications. Both techniques leverage platinum's excellent conductivity, chemical stability, and luster but differ in thickness, cost, and application suitability.

Understanding the Platinum Electroplating Process

Platinum electroplating involves depositing a thin, uniform layer of platinum onto a substrate by using an electrolytic solution containing platinum ions, offering precise control over thickness and surface finish. This process enhances corrosion resistance, electrical conductivity, and aesthetic appeal of jewelry and industrial components without significantly altering the base material's dimensions. Compared to platinum cladding, which mechanically bonds a thicker platinum layer to the surface, electroplating provides superior precision and uniformity for delicate applications requiring fine detail.

The Science Behind Platinum Cladding

Platinum cladding involves bonding a thin layer of platinum to a base metal through metallurgical processes such as roll bonding or diffusion bonding, creating a durable composite with enhanced corrosion resistance and aesthetic appeal. Unlike electroplating, which deposits a fine platinum layer via an electrolytic process prone to wear and thinning over time, cladding produces a mechanically bonded layer that maintains consistent thickness and improved structural integrity. The science behind platinum cladding leverages high-temperature pressure and metallurgical affinity between metals to achieve a homogeneous, resilient surface ideal for industrial and jewelry applications.

Key Differences Between Electroplating and Cladding

Platinum electroplating involves depositing a thin layer of platinum onto a substrate using an electrolytic process, resulting in a delicate, uniform coating ideal for detailed designs but prone to wear over time. Platinum cladding consists of bonding a thicker layer of platinum to a base metal through mechanical or diffusion processes, providing greater durability and resistance to corrosion and abrasion. The key differences lie in the thickness of the platinum layer, durability, and cost, with electroplating being more economical but less robust compared to the long-lasting, heavier platinum cladding.

Material Thickness: Electroplating vs Cladding

Platinum electroplating involves applying a thin layer of platinum, typically ranging from 0.5 to 5 microns, which provides surface-level protection and aesthetic appeal but offers limited durability. Platinum cladding, however, consists of a substantially thicker layer, often exceeding 20 microns, bonded to a base metal, resulting in enhanced wear resistance and longevity. This significant difference in material thickness makes cladding more suitable for applications requiring sustained platinum performance and durability.

Durability and Wear Resistance Comparison

Platinum electroplating creates a thin, uniform layer of platinum on the surface of a base metal, offering good corrosion resistance and moderate wear protection, but its durability can diminish over time due to the thinness of the coating. Platinum cladding involves bonding a thicker layer of platinum to the substrate, providing superior durability and enhanced wear resistance suitable for high-use applications. The thicker platinum cladding maintains its appearance longer under abrasion and mechanical stress compared to electroplating, making it ideal for jewelry and industrial components requiring longevity.

Application Areas of Platinum Electroplating

Platinum electroplating is extensively used in the electronics industry to enhance the corrosion resistance and conductivity of components such as connectors, electrodes, and circuit boards. It is also applied in the automotive sector for catalytic converters where a thin, uniform platinum layer improves durability and catalytic efficiency. In jewelry manufacturing, platinum electroplating provides a cost-effective alternative to solid platinum, offering a high-quality finish on silver or base metals.

Industrial Uses of Platinum Clad Materials

Platinum cladding offers a cost-effective solution for industrial applications requiring corrosion resistance and high conductivity without the expense of solid platinum. Commonly used in chemical processing equipment, platinum-clad materials provide durability and enhanced chemical inertness in harsh environments. Industries such as automotive catalytic converters and electronics benefit from platinum cladding's balance of performance and economic efficiency.

Cost Analysis: Electoplated vs Clad Platinum Products

Platinum electroplating offers a thinner layer of platinum, significantly reducing the amount of precious metal used and lowering initial costs compared to platinum cladding. Platinum cladding involves bonding a thicker, solid layer of platinum to a base metal, resulting in higher durability but increased material and manufacturing expenses. Cost analysis reveals electroplated platinum products suit budget-conscious applications, while clad platinum products provide long-term value in high-wear environments despite their higher upfront investment.

Choosing the Right Platinum Enhancement Technique

Platinum electroplating offers a thin, uniform layer of platinum ideal for intricate designs requiring high precision and corrosion resistance, whereas platinum cladding involves bonding a thicker platinum sheet to a base metal, providing greater durability and luxurious feel at a higher cost. For applications demanding detailed surface finishes and maximum conductivity, electroplating is preferred, while cladding suits jewelry and industrial parts needing robust wear by leveraging mechanical strength. Evaluating factors like desired thickness, wear resistance, project budget, and application environment ensures selection of the optimal platinum enhancement technique.

Platinum Electroplating vs Platinum Cladding Infographic

materialdif.com

materialdif.com