Platinum wire offers flexibility and precision ideal for intricate jewelry designs and detailed craftsmanship, while platinum sheet provides a flat, malleable surface perfect for creating broad, sturdy components and larger pieces. The choice between platinum wire and sheet depends on the specific application, with wire suited for fine, delicate work and sheet favored for its versatility in shaping and engraving. Both forms maintain the durability and high-quality finish intrinsic to platinum, ensuring lasting elegance and strength.

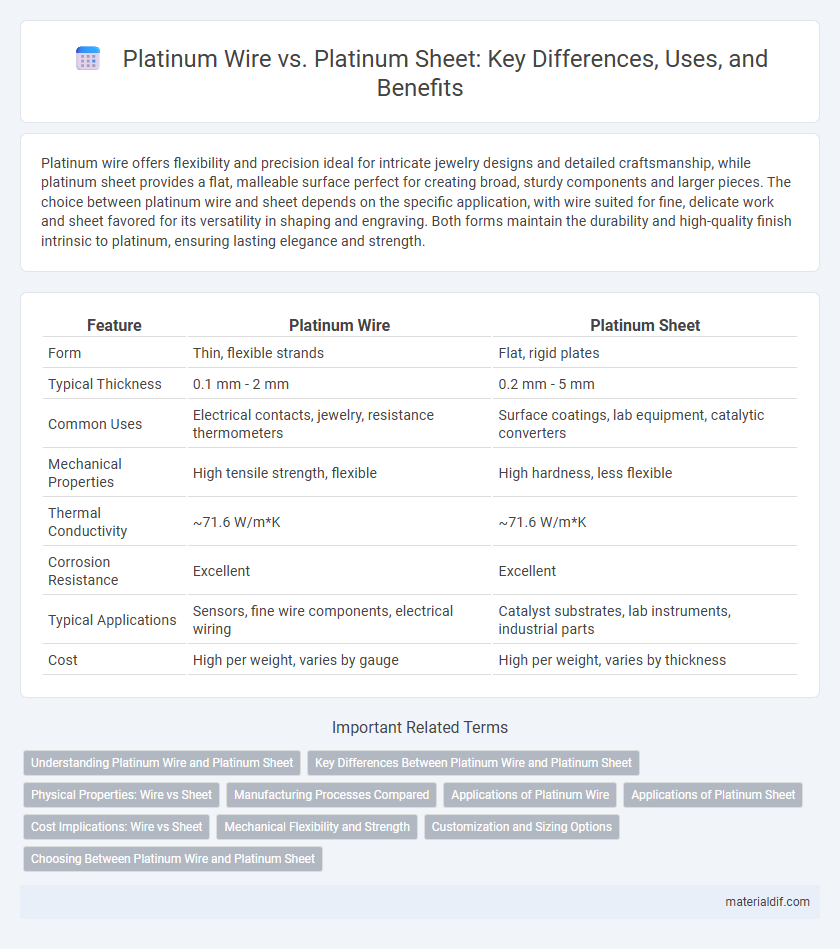

Table of Comparison

| Feature | Platinum Wire | Platinum Sheet |

|---|---|---|

| Form | Thin, flexible strands | Flat, rigid plates |

| Typical Thickness | 0.1 mm - 2 mm | 0.2 mm - 5 mm |

| Common Uses | Electrical contacts, jewelry, resistance thermometers | Surface coatings, lab equipment, catalytic converters |

| Mechanical Properties | High tensile strength, flexible | High hardness, less flexible |

| Thermal Conductivity | ~71.6 W/m*K | ~71.6 W/m*K |

| Corrosion Resistance | Excellent | Excellent |

| Typical Applications | Sensors, fine wire components, electrical wiring | Catalyst substrates, lab instruments, industrial parts |

| Cost | High per weight, varies by gauge | High per weight, varies by thickness |

Understanding Platinum Wire and Platinum Sheet

Platinum wire offers exceptional flexibility and conductivity, making it ideal for precision applications such as electrical contacts and laboratory use. Platinum sheet provides a stable, flat surface perfect for fabrication, jewelry making, and catalytic converters due to its durability and corrosion resistance. Selecting between platinum wire and sheet depends on the specific requirements for shape, strength, and surface area in industrial or artistic projects.

Key Differences Between Platinum Wire and Platinum Sheet

Platinum wire offers exceptional flexibility and precision for applications requiring intricate shaping, while platinum sheets provide a flat, uniform surface ideal for stamping, cutting, and large-scale fabrication. The key differences lie in their form factors, with wire typically ranging from thin gauges suitable for jewelry and electronics, whereas sheets vary in thickness and size for structural or decorative uses. Material properties remain consistent across both forms, but manufacturing processes and application suitability distinguish platinum wire from platinum sheet.

Physical Properties: Wire vs Sheet

Platinum wire exhibits high tensile strength and excellent flexibility, making it ideal for applications requiring intricate shapes and repeated bending without cracking. In contrast, platinum sheet offers superior flatness and surface uniformity, providing an ideal substrate for thin-film coatings and precision engineering components. Both forms maintain platinum's exceptional corrosion resistance and high melting point, but the wire excels in structural resilience while the sheet delivers dimensional stability.

Manufacturing Processes Compared

Platinum wire is typically produced through a series of precise processes including melting, casting, rolling, and drawing to achieve high tensile strength and flexibility for intricate applications such as electrical components and jewelry. In contrast, platinum sheets are manufactured primarily by melting and rolling platinum ingots into flat, uniform thicknesses suitable for industrial uses like catalytic converters and electronic devices. The key difference lies in the drawing process exclusive to wire production, which enhances malleability and elongation properties, while sheet manufacturing emphasizes controlled rolling for consistent surface quality and thickness.

Applications of Platinum Wire

Platinum wire is extensively used in electrical applications due to its excellent conductivity and resistance to corrosion, making it ideal for thermocouples, electrodes, and resistance heating elements. Its flexibility and strength allow for precise winding in laboratory equipment and fine wiring in medical devices, enhancing performance in sensitive environments. Compared to platinum sheets, platinum wire offers superior adaptability in applications requiring intricate shapes or high tensile strength.

Applications of Platinum Sheet

Platinum sheet is widely used in industrial applications requiring precise corrosion resistance and excellent electrical conductivity, such as in laboratory equipment, electrical contacts, and catalytic converters for chemical reactions. Its flat, uniform surface makes it ideal for creating electrodes and components subjected to harsh chemical environments, ensuring stability and durability. Compared to platinum wire, platinum sheet offers better mechanical support and surface area for applications in electronics and medical devices.

Cost Implications: Wire vs Sheet

Platinum wire generally incurs higher costs compared to platinum sheet due to the additional manufacturing processes like drawing and annealing that increase labor and production expenses. Platinum sheets benefit from lower material wastage and simpler fabrication techniques, making them more cost-effective for bulk applications. The price difference is influenced by the purity, thickness, and dimensions required, with wire often priced higher per gram than sheet of equivalent grade.

Mechanical Flexibility and Strength

Platinum wire exhibits superior mechanical flexibility compared to platinum sheet, making it ideal for applications requiring repeated bending or intricate shapes without fracturing. In contrast, platinum sheets offer higher tensile strength and rigidity, suitable for structural uses where durability and resistance to deformation under load are critical. The choice between platinum wire and sheet depends on balancing flexibility needs with strength requirements in specialized industrial or jewelry applications.

Customization and Sizing Options

Platinum wire offers exceptional flexibility for custom projects, allowing precise diameter and length adjustments to meet specific design requirements. In contrast, platinum sheet provides versatile sizing options with customizable thickness and dimensions, ideal for applications needing flat, uniform surfaces. Both forms cater to tailored needs, with wire excelling in intricate, three-dimensional work and sheets suited for detailed, planar craftsmanship.

Choosing Between Platinum Wire and Platinum Sheet

Choosing between platinum wire and platinum sheet depends on the specific application requirements such as flexibility, strength, and surface area. Platinum wire offers excellent tensile strength and is ideal for intricate designs or electrical components requiring conductivity and durability. Platinum sheet provides a larger surface area, making it suitable for applications needing uniform thickness and ease of cutting or shaping into larger, flat components.

Platinum Wire vs Platinum Sheet Infographic

materialdif.com

materialdif.com