Platinum crucibles offer superior chemical resistance and high melting points, making them ideal for high-temperature applications where durability and contamination prevention are crucial. Ceramic crucibles provide excellent thermal shock resistance and cost-effectiveness but may be prone to cracking under extreme conditions. Choosing between a platinum and ceramic crucible depends on the specific requirements for thermal stability, chemical reactivity, and budget constraints.

Table of Comparison

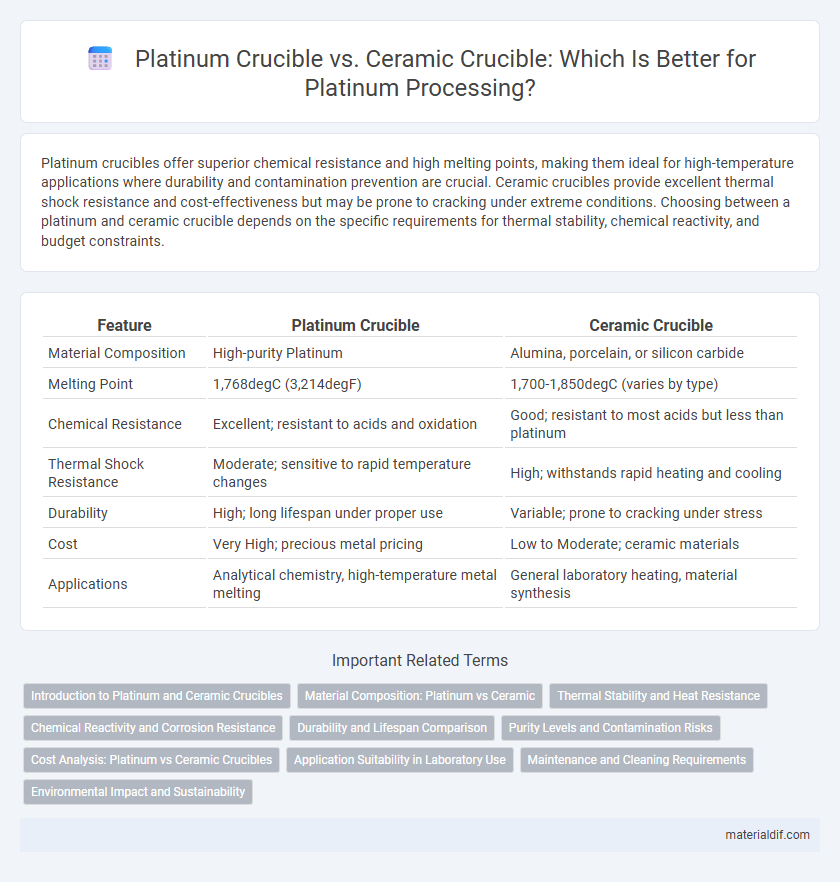

| Feature | Platinum Crucible | Ceramic Crucible |

|---|---|---|

| Material Composition | High-purity Platinum | Alumina, porcelain, or silicon carbide |

| Melting Point | 1,768degC (3,214degF) | 1,700-1,850degC (varies by type) |

| Chemical Resistance | Excellent; resistant to acids and oxidation | Good; resistant to most acids but less than platinum |

| Thermal Shock Resistance | Moderate; sensitive to rapid temperature changes | High; withstands rapid heating and cooling |

| Durability | High; long lifespan under proper use | Variable; prone to cracking under stress |

| Cost | Very High; precious metal pricing | Low to Moderate; ceramic materials |

| Applications | Analytical chemistry, high-temperature metal melting | General laboratory heating, material synthesis |

Introduction to Platinum and Ceramic Crucibles

Platinum crucibles offer exceptional resistance to high temperatures and chemical corrosion, making them ideal for handling aggressive substances in laboratory settings. Ceramic crucibles, typically made from materials like alumina or porcelain, provide excellent thermal stability and insulation properties while being more affordable than platinum. Both types are crucial in processes requiring precise temperature control and contaminant-free environments, but platinum crucibles are preferred for high-purity and high-temperature applications due to their unmatched durability and inertness.

Material Composition: Platinum vs Ceramic

Platinum crucibles are composed of pure platinum or platinum alloys, offering exceptional resistance to high temperatures, chemical corrosion, and oxidation. Ceramic crucibles are primarily made from alumina or silica-based materials, providing good thermal stability but limited chemical resistance compared to platinum. The superior material composition of platinum makes it ideal for high-precision applications involving reactive substances.

Thermal Stability and Heat Resistance

Platinum crucibles exhibit superior thermal stability and heat resistance compared to ceramic crucibles, maintaining structural integrity at temperatures exceeding 1700degC without deformation or cracking. Ceramic crucibles typically withstand temperatures up to 1600degC but are more prone to thermal shock and fracture under rapid temperature changes. The excellent thermal conductivity and corrosion resistance of platinum make it ideal for applications requiring repeated high-temperature cycles and reactive environments.

Chemical Reactivity and Corrosion Resistance

Platinum crucibles exhibit superior chemical reactivity resistance, maintaining stability even when exposed to aggressive acids and high-temperature melts, making them ideal for melting and analysis of reactive metals. Ceramic crucibles, while offering good resistance to thermal shock and corrosion from less aggressive substances, tend to react with strong alkalis and certain metal oxides, leading to contamination or structural degradation. The exceptional corrosion resistance of platinum crucibles ensures high purity in samples and longer lifespan under extreme chemical conditions compared to standard ceramic options.

Durability and Lifespan Comparison

Platinum crucibles exhibit superior durability due to their high melting point of 1768degC and excellent resistance to chemical corrosion, resulting in a longer lifespan compared to ceramic crucibles, which typically have lower thermal shock resistance and can degrade faster under extreme conditions. Ceramic crucibles, often made from alumina or zirconia, provide good thermal insulation but are prone to cracking and wear with repeated heating cycles, limiting their operational lifespan in high-temperature applications. The inherent robustness and corrosion resistance of platinum crucibles make them ideal for prolonged use in harsh chemical environments, whereas ceramic crucibles require more frequent replacement.

Purity Levels and Contamination Risks

Platinum crucibles offer exceptionally high purity levels, making them ideal for processes requiring minimal contamination, as they resist chemical reactions and withstand extreme temperatures without leaching impurities. Ceramic crucibles, while cost-effective, generally have higher contamination risks due to their porous nature and potential for chemical interaction, which can introduce impurities during heating. The superior inertness and durability of platinum crucibles ensure that samples remain uncontaminated, a critical factor in high-precision laboratory and industrial applications.

Cost Analysis: Platinum vs Ceramic Crucibles

Platinum crucibles, known for exceptional corrosion resistance and high melting point, typically cost significantly more than ceramic crucibles, impacting budget considerations in laboratory settings. Ceramic crucibles offer a lower-cost alternative with decent thermal stability but may suffer from brittleness and chemical reactivity limitations. Cost analysis should weigh the initial investment and long-term durability, with platinum crucibles favored for high-precision, high-temperature applications despite their premium price.

Application Suitability in Laboratory Use

Platinum crucibles offer exceptional chemical resistance and withstand extreme temperatures, making them ideal for precise analytical procedures and high-temperature reactions in laboratory settings. Ceramic crucibles provide excellent thermal insulation and are suitable for general heating applications but may not resist aggressive chemical environments as effectively as platinum. Selecting between platinum and ceramic crucibles depends on the specific experimental requirements, balancing cost with chemical durability and thermal performance.

Maintenance and Cleaning Requirements

Platinum crucibles require minimal maintenance due to their corrosion resistance and ability to withstand high temperatures without degrading, reducing the need for frequent cleaning. Ceramic crucibles, although chemically inert, are more porous and can absorb residues, necessitating thorough cleaning after each use to prevent contamination. Proper cleaning of ceramic crucibles often involves soaking and scrubbing to remove absorbed materials, whereas platinum crucibles can typically be cleaned with simple rinsing or mild solvents.

Environmental Impact and Sustainability

Platinum crucibles exhibit superior durability and corrosion resistance, resulting in a longer lifespan and reduced waste generation compared to ceramic crucibles, which are more prone to cracking and require frequent replacement. The energy-intensive mining and refining processes for platinum have environmental implications, but their extended usability mitigates frequent resource consumption. Ceramic crucibles, while made from abundant materials, often demand higher energy input during production and contribute to landfill waste due to breakage, making platinum crucibles a more sustainable option over time despite the initial environmental costs.

Platinum Crucible vs Ceramic Crucible Infographic

materialdif.com

materialdif.com