Platinum plating involves coating a base metal with a thin layer of platinum, offering an affordable and visually appealing finish but with limited durability and potential wear over time. Solid platinum consists entirely of pure platinum, providing exceptional strength, longevity, and resistance to tarnish, making it a premium choice for fine jewelry and luxury items. Choosing between platinum plating and solid platinum depends on budget, desired durability, and long-term value preferences.

Table of Comparison

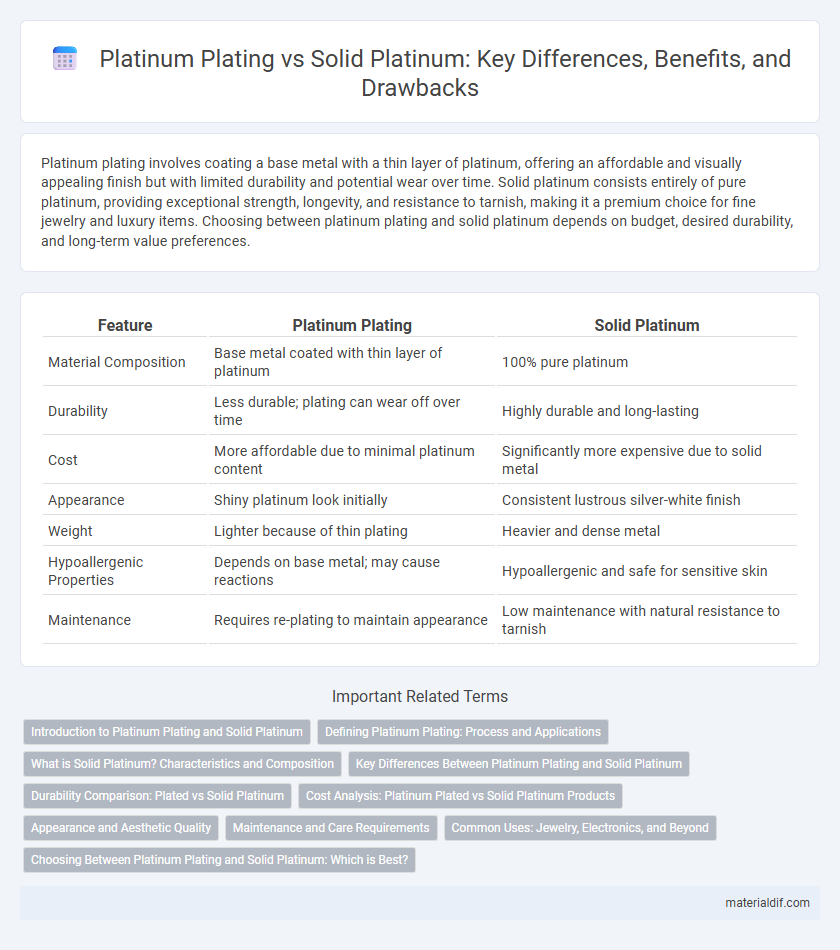

| Feature | Platinum Plating | Solid Platinum |

|---|---|---|

| Material Composition | Base metal coated with thin layer of platinum | 100% pure platinum |

| Durability | Less durable; plating can wear off over time | Highly durable and long-lasting |

| Cost | More affordable due to minimal platinum content | Significantly more expensive due to solid metal |

| Appearance | Shiny platinum look initially | Consistent lustrous silver-white finish |

| Weight | Lighter because of thin plating | Heavier and dense metal |

| Hypoallergenic Properties | Depends on base metal; may cause reactions | Hypoallergenic and safe for sensitive skin |

| Maintenance | Requires re-plating to maintain appearance | Low maintenance with natural resistance to tarnish |

Introduction to Platinum Plating and Solid Platinum

Platinum plating involves coating a base metal with a thin layer of platinum to achieve the look and some benefits of platinum at a lower cost. Solid platinum refers to jewelry or items made entirely from pure platinum, offering maximum durability, hypoallergenic properties, and intrinsic value. Platinum plating is ideal for affordable luxury, while solid platinum is preferred for long-term investment and premium quality.

Defining Platinum Plating: Process and Applications

Platinum plating involves electrochemically depositing a thin layer of platinum onto the surface of a base metal, enhancing its corrosion resistance, durability, and aesthetic appeal without the cost of solid platinum. This process is widely used in jewelry, electronics, and automotive components where platinum's catalytic and conductive properties improve performance and longevity. Unlike solid platinum items, which are made entirely of the precious metal, platinum plating offers a cost-effective way to achieve similar surface benefits with significantly reduced material consumption.

What is Solid Platinum? Characteristics and Composition

Solid platinum is a precious metal composed primarily of pure platinum, typically with a purity of 95% or higher, known for its exceptional density, durability, and resistance to tarnish. It exhibits a naturally lustrous silvery-white appearance and maintains its brilliance over time due to its high resistance to corrosion and wear. Solid platinum's composition and intrinsic properties make it ideal for fine jewelry and industrial applications requiring strong, long-lasting materials.

Key Differences Between Platinum Plating and Solid Platinum

Platinum plating involves coating a base metal with a thin layer of platinum, which provides a similar appearance at a lower cost but can wear off over time, unlike solid platinum that consists entirely of the precious metal and offers superior durability and intrinsic value. Solid platinum jewelry is heavier and hypoallergenic, making it ideal for sensitive skin, whereas plated items may cause allergic reactions due to underlying metals exposed as the plating fades. The price disparity is significant, with solid platinum commanding a premium price because of its density, purity, and lasting quality compared to the affordable yet less enduring nature of platinum-plated pieces.

Durability Comparison: Plated vs Solid Platinum

Solid platinum offers superior durability compared to platinum plating, as it is a dense and malleable precious metal that withstands scratches, tarnish, and everyday wear more effectively. Platinum plating consists of a thin layer of platinum applied over base metals, making it more prone to wear and exposing the underlying material over time. The longevity of solid platinum jewelry far exceeds that of platinum-plated items, ensuring lasting resistance to damage and maintaining its lustrous appearance.

Cost Analysis: Platinum Plated vs Solid Platinum Products

Platinum plating offers a cost-effective alternative to solid platinum by using a thin layer of platinum over a base metal, significantly reducing material expenses while maintaining the appearance of platinum. Solid platinum products, priced higher due to pure platinum content and durability, provide superior value for long-term investment and resale potential. Consumers seeking affordable luxury often prefer platinum-plated items, whereas solid platinum is favored for its intrinsic worth and longevity.

Appearance and Aesthetic Quality

Platinum plating offers a shiny, reflective surface that mimics the appearance of solid platinum but may wear off over time, revealing the base metal underneath. Solid platinum maintains its lustrous, silvery-white hue with exceptional durability and resistance to tarnish, ensuring long-lasting aesthetic appeal. The dense, heavyweight feel of solid platinum enhances its perceived value and luxurious appearance compared to the thinner, more delicate finish of platinum plating.

Maintenance and Care Requirements

Platinum plating requires regular upkeep to prevent the thin layer from wearing off and exposing the base metal, often necessitating periodic re-plating to maintain its luster. Solid platinum is highly durable and resistant to tarnish, needing minimal maintenance beyond occasional cleaning with mild soap and water to preserve its natural shine. Understanding these differences helps consumers choose between the affordability of plated options and the lasting value of solid platinum jewelry.

Common Uses: Jewelry, Electronics, and Beyond

Platinum plating offers a cost-effective way to achieve the lustrous appearance of solid platinum, commonly used in jewelry to provide durability and a high-end finish without the full expense. In electronics, solid platinum's excellent conductivity and resistance to corrosion make it ideal for high-precision connectors and medical devices, whereas platinum plating enhances surface performance in less critical components. Beyond these uses, solid platinum is favored in catalytic converters and laboratory equipment for its chemical stability, while platinum plating serves as a protective coating in various industrial applications.

Choosing Between Platinum Plating and Solid Platinum: Which is Best?

Choosing between platinum plating and solid platinum depends on budget and durability preferences; solid platinum offers superior strength, hypoallergenic properties, and lasting value, making it ideal for fine jewelry and long-term wear. Platinum plating provides an affordable alternative with the appearance of platinum but tends to wear off over time, revealing the base metal underneath. For investments in longevity and premium quality, solid platinum is the optimal choice.

Platinum Plating vs Solid Platinum Infographic

materialdif.com

materialdif.com