Platinum soldering creates strong, durable joints by melting a filler metal to bond platinum pieces, ideal for intricate designs requiring seamless connections. Laser welding uses concentrated light energy to precisely fuse platinum components with minimal heat impact, preserving fine details and reducing the need for post-weld cleanup. Both techniques offer reliable results, but laser welding excels in precision and speed, making it preferable for delicate or complex platinum jewelry work.

Table of Comparison

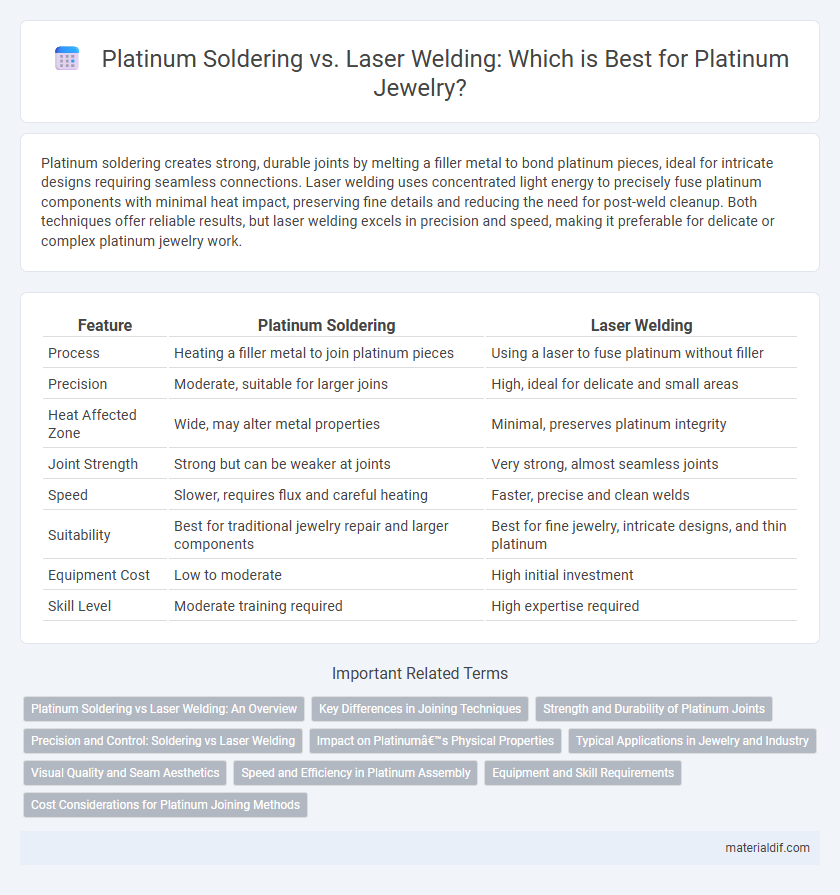

| Feature | Platinum Soldering | Laser Welding |

|---|---|---|

| Process | Heating a filler metal to join platinum pieces | Using a laser to fuse platinum without filler |

| Precision | Moderate, suitable for larger joins | High, ideal for delicate and small areas |

| Heat Affected Zone | Wide, may alter metal properties | Minimal, preserves platinum integrity |

| Joint Strength | Strong but can be weaker at joints | Very strong, almost seamless joints |

| Speed | Slower, requires flux and careful heating | Faster, precise and clean welds |

| Suitability | Best for traditional jewelry repair and larger components | Best for fine jewelry, intricate designs, and thin platinum |

| Equipment Cost | Low to moderate | High initial investment |

| Skill Level | Moderate training required | High expertise required |

Platinum Soldering vs Laser Welding: An Overview

Platinum soldering involves joining metals using a filler material with a lower melting point, ideal for delicate jewelry and precision instruments due to its controlled heat application. Laser welding uses concentrated laser beams to fuse platinum pieces with high precision and minimal thermal distortion, making it suitable for intricate designs and repairs. Both techniques demand expertise, but laser welding offers superior control and strength in complex or fine platinum work.

Key Differences in Joining Techniques

Platinum soldering involves melting a filler alloy with a lower melting point than the base metal to join parts, producing strong bonds suitable for complex shapes but with potential heat-affected zones. Laser welding uses a focused laser beam to precisely melt the platinum edges directly, offering minimal thermal distortion and higher joint strength with faster processing times. The choice depends on factors such as joint geometry, required strength, and sensitivity to heat, with laser welding favored for intricate or high-precision applications.

Strength and Durability of Platinum Joints

Platinum soldering creates strong joints by using a filler metal with a slightly lower melting point, resulting in durable but potentially weaker connections compared to laser welding. Laser welding fuses platinum directly, preserving the metal's integrity and producing exceptionally strong, precise, and highly durable joints. This makes laser welding the preferred technique for applications demanding superior mechanical strength and long-lasting wear resistance in platinum components.

Precision and Control: Soldering vs Laser Welding

Platinum soldering offers precise control by allowing gradual heating and careful joining of delicate parts, ideal for intricate jewelry work. Laser welding enhances precision through focused, high-energy beams that provide exact, localized heat with minimal thermal distortion. Both methods achieve high accuracy, but laser welding excels in controlling heat input, reducing risks of damage or deformation in platinum components.

Impact on Platinum’s Physical Properties

Platinum soldering can cause thermal distortion and alloying that alters the metal's hardness and ductility, potentially weakening its natural corrosion resistance. Laser welding produces a precise, localized heat affected zone, preserving the platinum's grain structure and maintaining its original tensile strength and elongation properties. The controlled heat input of laser welding minimizes residual stresses and reduces the risk of micro-cracking, ensuring superior physical stability in platinum jewelry or components.

Typical Applications in Jewelry and Industry

Platinum soldering is commonly used in jewelry for delicate repairs and intricate designs, allowing precise joining of thin components without altering the metal's appearance. Laser welding, favored in both jewelry and industrial applications, offers high precision and strong joints ideal for complex structures and small-scale manufacturing. Industrial uses of laser welding extend to aerospace and electronics, where platinum's corrosion resistance and conductivity are critical.

Visual Quality and Seam Aesthetics

Platinum soldering produces seams with slight discoloration and visible joint lines, often requiring additional polishing to enhance visual appeal, while laser welding creates nearly invisible seams with minimal heat-affected zones, preserving the metal's original finish. The precision of laser welding results in finer, cleaner edges and superior aesthetics, making it ideal for high-end jewelry and intricate platinum components. In contrast, soldering may introduce flux residues and microscopic surface imperfections that can diminish the overall seam quality.

Speed and Efficiency in Platinum Assembly

Platinum soldering offers reliable joins but typically requires longer heating times and careful temperature control, which can slow down the assembly process. Laser welding delivers superior speed and precision by focusing energy precisely on the weld area, minimizing heat-affected zones and reducing cycle times in platinum assembly. This efficiency advantage makes laser welding the preferred method for high-volume production and intricate platinum components.

Equipment and Skill Requirements

Platinum soldering requires precise temperature control equipment and skilled operators to manage flux application and prevent metal contamination. Laser welding demands advanced laser systems with adjustable power settings and high operator expertise to execute accurate welds without compromising the platinum's integrity. Both techniques necessitate specialized training, but laser welding offers greater precision and reduced thermal distortion in platinum jewelry fabrication.

Cost Considerations for Platinum Joining Methods

Platinum soldering generally offers a lower initial cost due to simpler equipment requirements and shorter preparation times, making it suitable for small-scale or less complex joins. Laser welding, while involving higher upfront investment for specialized machinery and operator training, delivers superior precision and minimal heat distortion, reducing the likelihood of costly defects in high-value or intricate platinum components. Evaluating long-term production scales and quality control needs helps determine the most cost-effective joining method for platinum applications.

Platinum Soldering vs Laser Welding Infographic

materialdif.com

materialdif.com