Lab-grown platinum offers a sustainable and environmentally friendly alternative to mined platinum, reducing the ecological impact associated with traditional mining practices. It maintains the same chemical composition, durability, and aesthetic appeal as mined platinum, ensuring high-quality standards for luxury products and jewelry. The controlled production process of lab-grown platinum allows for greater purity and ethical sourcing transparency compared to mined platinum.

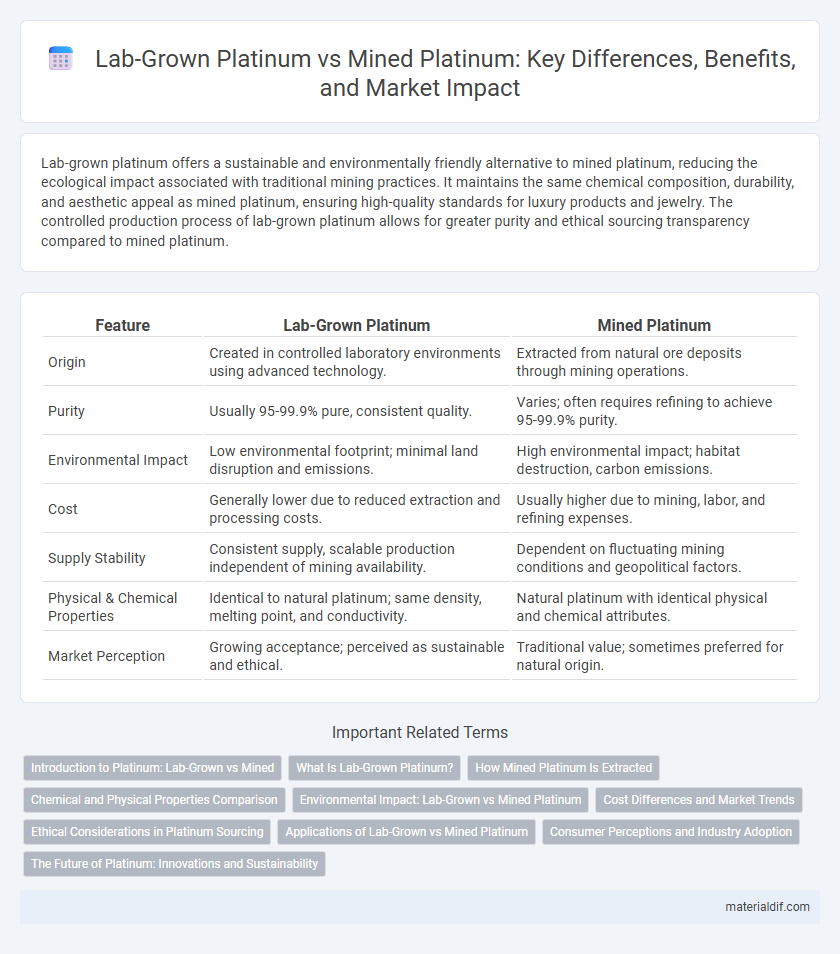

Table of Comparison

| Feature | Lab-Grown Platinum | Mined Platinum |

|---|---|---|

| Origin | Created in controlled laboratory environments using advanced technology. | Extracted from natural ore deposits through mining operations. |

| Purity | Usually 95-99.9% pure, consistent quality. | Varies; often requires refining to achieve 95-99.9% purity. |

| Environmental Impact | Low environmental footprint; minimal land disruption and emissions. | High environmental impact; habitat destruction, carbon emissions. |

| Cost | Generally lower due to reduced extraction and processing costs. | Usually higher due to mining, labor, and refining expenses. |

| Supply Stability | Consistent supply, scalable production independent of mining availability. | Dependent on fluctuating mining conditions and geopolitical factors. |

| Physical & Chemical Properties | Identical to natural platinum; same density, melting point, and conductivity. | Natural platinum with identical physical and chemical attributes. |

| Market Perception | Growing acceptance; perceived as sustainable and ethical. | Traditional value; sometimes preferred for natural origin. |

Introduction to Platinum: Lab-Grown vs Mined

Lab-grown platinum is synthesized using advanced chemical vapor deposition or electrochemical processes that replicate its crystalline structure, resulting in pure, conflict-free metal. Mined platinum is extracted from underground deposits, involving extensive mining operations that impact the environment and require significant energy consumption. Both forms exhibit identical chemical properties, but lab-grown platinum offers a sustainable alternative with reduced ecological footprint and traceability assurance.

What Is Lab-Grown Platinum?

Lab-grown platinum is produced through advanced technological processes such as chemical vapor deposition or high-pressure high-temperature synthesis, replicating the natural formation of platinum in a controlled environment. This method yields platinum with identical chemical composition and physical properties to mined platinum, offering a sustainable and ethical alternative. Lab-grown platinum reduces environmental impact by minimizing mining disruptions and conserves natural resources while maintaining the metal's renowned durability and luster.

How Mined Platinum Is Extracted

Mined platinum is extracted through underground and open-pit mining techniques, involving drilling, blasting, and hauling ore to processing facilities. The ore is crushed and subjected to flotation to concentrate the platinum group metals before refining. This process has a significant environmental impact due to habitat disruption and energy consumption compared to lab-grown alternatives.

Chemical and Physical Properties Comparison

Lab-grown platinum and mined platinum share identical chemical properties, as both consist of pure platinum (Pt) with the atomic number 78, exhibiting excellent resistance to corrosion and oxidation. Physically, lab-grown platinum crystals can be produced with fewer impurities and more uniform grain structures, potentially enhancing hardness and durability compared to natural mined platinum, which often contains trace elements and inclusions. Both forms maintain a high melting point of 1,768degC and exceptional density around 21.45 g/cm3, making them virtually indistinguishable in industrial and jewelry applications.

Environmental Impact: Lab-Grown vs Mined Platinum

Lab-grown platinum significantly reduces environmental impact by minimizing mining-related land disruption, water usage, and carbon emissions compared to traditional platinum extraction. Mining operations often result in ecosystem degradation and habitat loss, while lab-grown methods use controlled processes with lower energy requirements and negligible waste generation. This sustainable approach supports environmental conservation and resource efficiency in platinum production.

Cost Differences and Market Trends

Lab-grown platinum typically costs 20-40% less than mined platinum due to lower extraction and environmental compliance expenses. Market trends indicate rising demand for lab-grown platinum driven by sustainability concerns and technological advancements in manufacturing. Industry reports project a growing market share for lab-grown platinum, especially in jewelry and catalytic converter applications, challenging traditional mining dominance.

Ethical Considerations in Platinum Sourcing

Lab-grown platinum eliminates the ethical concerns associated with traditional mining, such as environmental degradation, human rights violations, and unfair labor practices often linked to mined platinum extraction. Ethical sourcing in lab-grown platinum ensures transparency, reduces carbon footprint, and supports sustainable production methods, meeting the increasing consumer demand for responsible luxury metals. Mined platinum, while natural, faces ongoing scrutiny due to geopolitical instability and the exploitation risks in mining regions, making lab-grown alternatives a preferable choice for ethically conscious buyers.

Applications of Lab-Grown vs Mined Platinum

Lab-grown platinum and mined platinum both serve critical roles in automotive catalytic converters, jewelry, and electronics, with lab-grown platinum gaining traction due to its sustainable production and comparable purity. In industrial applications such as chemical processing and fuel cells, mined platinum remains preferred for its large-scale availability and proven reliability. The medical field increasingly adopts lab-grown platinum for surgical instruments and implants, benefiting from its controlled quality and ethical sourcing.

Consumer Perceptions and Industry Adoption

Lab-grown platinum is gaining consumer trust due to its ethical sourcing and lower environmental impact compared to traditionally mined platinum, which often faces scrutiny for ecological and social concerns. Industry adoption is accelerating as manufacturers prioritize sustainability and cost-efficiency, with lab-grown platinum offering consistent quality and traceability. Market reports indicate a growing preference among younger consumers for lab-grown metals, driving innovation and broader acceptance in luxury jewelry and industrial applications.

The Future of Platinum: Innovations and Sustainability

Lab-grown platinum offers a revolutionary approach to sustainable metal sourcing, reducing environmental impact and minimizing the carbon footprint compared to traditional mining. Advanced techniques in platinum synthesis are enhancing purity and scalability, making lab-grown platinum a viable alternative for industrial and jewelry applications. Ongoing innovations in recycling and circular economy practices further support the future demand for platinum while promoting ecological balance and resource efficiency.

Lab-Grown Platinum vs Mined Platinum Infographic

materialdif.com

materialdif.com