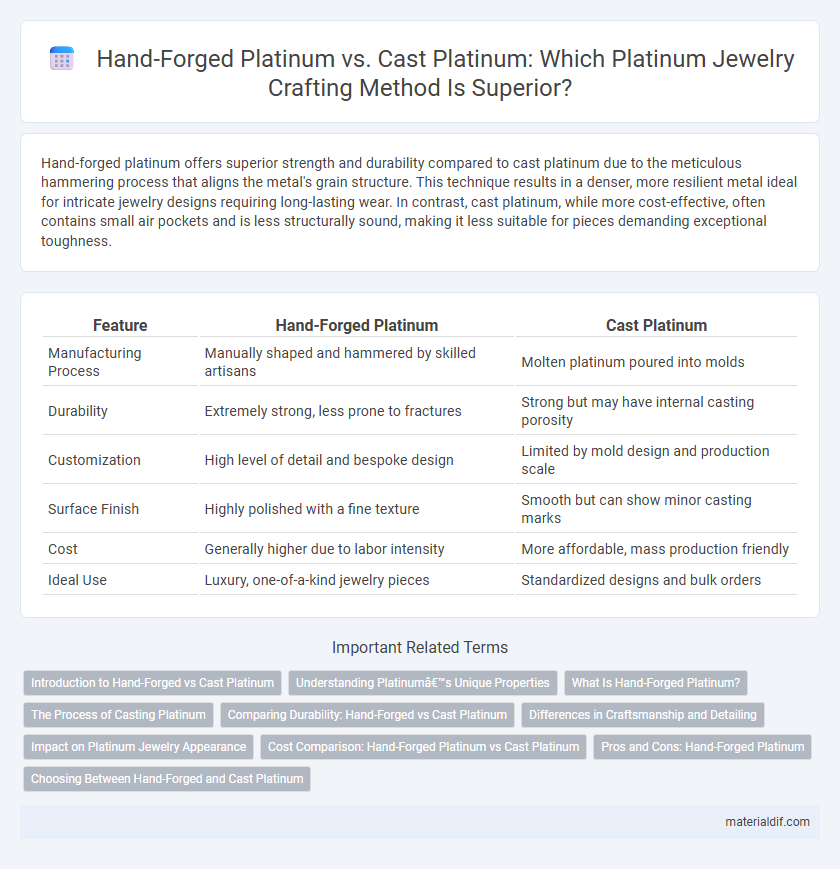

Hand-forged platinum offers superior strength and durability compared to cast platinum due to the meticulous hammering process that aligns the metal's grain structure. This technique results in a denser, more resilient metal ideal for intricate jewelry designs requiring long-lasting wear. In contrast, cast platinum, while more cost-effective, often contains small air pockets and is less structurally sound, making it less suitable for pieces demanding exceptional toughness.

Table of Comparison

| Feature | Hand-Forged Platinum | Cast Platinum |

|---|---|---|

| Manufacturing Process | Manually shaped and hammered by skilled artisans | Molten platinum poured into molds |

| Durability | Extremely strong, less prone to fractures | Strong but may have internal casting porosity |

| Customization | High level of detail and bespoke design | Limited by mold design and production scale |

| Surface Finish | Highly polished with a fine texture | Smooth but can show minor casting marks |

| Cost | Generally higher due to labor intensity | More affordable, mass production friendly |

| Ideal Use | Luxury, one-of-a-kind jewelry pieces | Standardized designs and bulk orders |

Introduction to Hand-Forged vs Cast Platinum

Hand-forged platinum involves shaping the metal by hammering and manipulating it at high temperatures, resulting in a denser, more durable structure ideal for intricate, custom jewelry. Cast platinum is produced by melting the metal and pouring it into molds, allowing for consistent shapes and mass production but often with slightly less structural integrity. Both methods offer unique advantages, with hand-forging favored for craftsmanship and longevity, while casting provides precision and efficiency.

Understanding Platinum’s Unique Properties

Hand-forged platinum showcases exceptional density and ductility, allowing jewelers to shape intricate designs with superior strength compared to cast platinum, which involves melting and molding. The metal's high melting point of 1768degC and remarkable malleability make hand-forging ideal for creating durable jewelry that resists wear and maintains its luster over time. Understanding these unique properties explains why hand-forged platinum offers enhanced structural integrity and longevity compared to cast alternatives.

What Is Hand-Forged Platinum?

Hand-forged platinum is a metalworking process where skilled artisans shape platinum by hammering and manipulating it at high temperatures, enhancing its density and durability. This technique produces a stronger, more resilient platinum piece compared to cast platinum, which is melted and poured into molds. The meticulous hand-forging process creates a unique texture and superior structural integrity in fine jewelry.

The Process of Casting Platinum

Casting platinum involves melting the metal at temperatures around 3,215degF (1,768degC) and pouring it into a mold to form intricate shapes with consistent detail. This process allows for mass production of platinum jewelry, ensuring uniformity and reducing labor intensity compared to hand forging. Precise temperature control and mold design are critical factors in casting platinum to achieve high-quality, durable pieces.

Comparing Durability: Hand-Forged vs Cast Platinum

Hand-forged platinum exhibits superior durability due to its denser molecular structure achieved through repeated hammering and shaping, resulting in increased resistance to bending and scratching. Cast platinum, formed by pouring molten metal into molds, may contain microscopic voids or inclusions, making it slightly less robust under daily wear. Jewelers often prefer hand-forged platinum for high-end jewelry pieces that demand enhanced strength and longevity.

Differences in Craftsmanship and Detailing

Hand-forged platinum jewelry exhibits superior craftsmanship with intricate detailing achieved through meticulous hammering and shaping, resulting in unique, one-of-a-kind pieces. In contrast, cast platinum involves melting the metal and pouring it into molds, allowing for consistent replication but often sacrificing the fine, personalized textures found in hand-forged items. The hand-forging process enhances durability and character, while casting prioritizes efficiency and uniformity in design.

Impact on Platinum Jewelry Appearance

Hand-forged platinum jewelry exhibits a more refined and unique texture due to the meticulous hammering and shaping process, creating a distinctive matte or satin finish that emphasizes craftsmanship. Cast platinum, produced by melting and pouring metal into molds, typically offers smoother surfaces and more intricate, consistent detailing ideal for complex designs. The choice between hand-forged and cast platinum significantly influences the jewelry's overall aesthetic, with hand-forged pieces showcasing artisanal character while cast pieces highlight precision and uniformity.

Cost Comparison: Hand-Forged Platinum vs Cast Platinum

Hand-forged platinum jewelry generally incurs higher production costs due to the labor-intensive craftsmanship and precision required, making it more expensive than cast platinum pieces. Cast platinum benefits from mass production techniques, reducing material waste and manufacturing time, which lowers overall expenses. Consumers often pay a premium for hand-forged platinum due to its superior durability and unique artisanal quality compared to the more uniform and affordable cast platinum.

Pros and Cons: Hand-Forged Platinum

Hand-forged platinum offers superior strength and durability due to the metal's dense grain structure formed during the forging process, making it ideal for intricate jewelry designs. This technique allows for precise customization and results in a more resilient piece, but it requires skilled craftsmanship and typically higher labor costs. However, hand-forged platinum pieces may take longer to produce compared to cast platinum, limiting scalability for mass production.

Choosing Between Hand-Forged and Cast Platinum

Choosing between hand-forged and cast platinum depends on desired durability and craftsmanship. Hand-forged platinum offers superior strength and a unique texture from skilled artisan work, ideal for custom, high-end jewelry. Cast platinum allows for intricate designs and mass production with consistent quality, making it suitable for detailed pieces and larger quantities.

Hand-Forged Platinum vs Cast Platinum Infographic

materialdif.com

materialdif.com