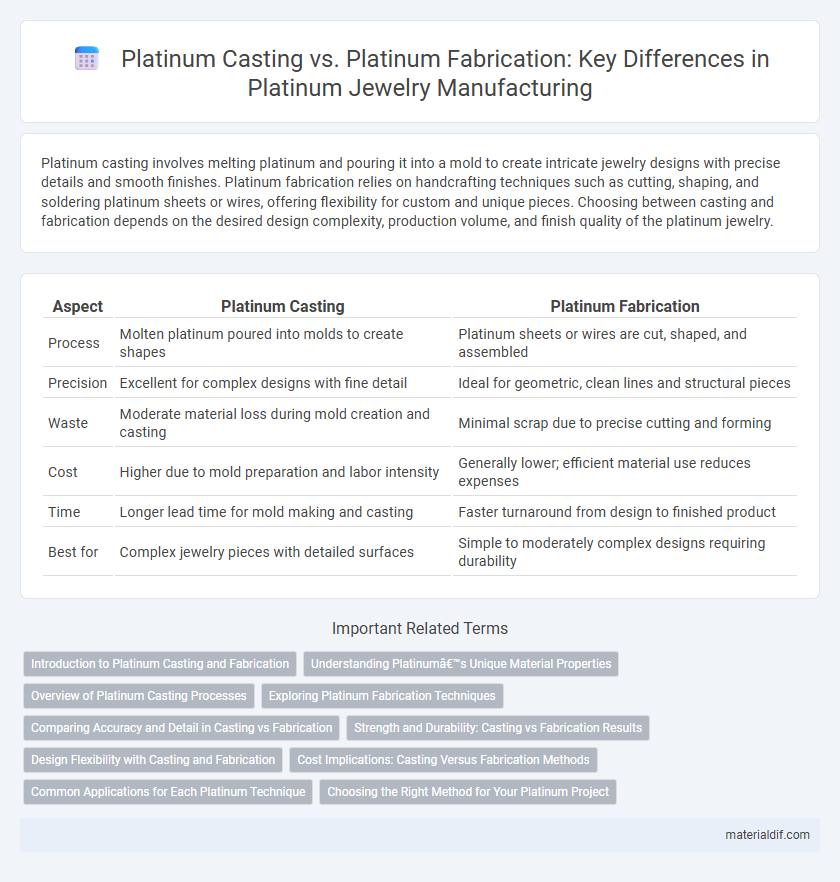

Platinum casting involves melting platinum and pouring it into a mold to create intricate jewelry designs with precise details and smooth finishes. Platinum fabrication relies on handcrafting techniques such as cutting, shaping, and soldering platinum sheets or wires, offering flexibility for custom and unique pieces. Choosing between casting and fabrication depends on the desired design complexity, production volume, and finish quality of the platinum jewelry.

Table of Comparison

| Aspect | Platinum Casting | Platinum Fabrication |

|---|---|---|

| Process | Molten platinum poured into molds to create shapes | Platinum sheets or wires are cut, shaped, and assembled |

| Precision | Excellent for complex designs with fine detail | Ideal for geometric, clean lines and structural pieces |

| Waste | Moderate material loss during mold creation and casting | Minimal scrap due to precise cutting and forming |

| Cost | Higher due to mold preparation and labor intensity | Generally lower; efficient material use reduces expenses |

| Time | Longer lead time for mold making and casting | Faster turnaround from design to finished product |

| Best for | Complex jewelry pieces with detailed surfaces | Simple to moderately complex designs requiring durability |

Introduction to Platinum Casting and Fabrication

Platinum casting involves pouring molten platinum into molds to create intricate jewelry shapes, offering excellent detail and allowing complex designs with superior strength and durability. Platinum fabrication, on the other hand, entails manually shaping platinum sheets and wires through techniques like soldering, bending, and hammering, providing greater control for custom, handcrafted pieces. Both methods are essential in platinum jewelry making, balancing precision with artisanal craftsmanship.

Understanding Platinum’s Unique Material Properties

Platinum casting allows for intricate shapes by melting and pouring the metal into molds, leveraging its high melting point of 1,768degC and excellent fluidity. Platinum fabrication involves shaping the metal through mechanical processes like rolling and stamping, benefiting from its exceptional malleability and resistance to wear. Understanding these unique properties ensures the selection of the appropriate method to achieve durability and precision in platinum jewelry and industrial components.

Overview of Platinum Casting Processes

Platinum casting involves melting platinum and pouring it into molds to create intricate jewelry designs, offering high precision and the ability to reproduce complex shapes. This process includes techniques such as lost wax casting and centrifugal casting, which ensure fine detail and structural integrity in the finished product. Compared to fabrication, casting allows for more elaborate designs but requires specialized equipment and handling due to platinum's high melting point.

Exploring Platinum Fabrication Techniques

Platinum fabrication techniques involve precise methods such as laser welding, soldering, and metal forming to shape intricate designs with minimal material waste and enhanced structural integrity. These processes offer greater customization and control compared to platinum casting, which relies on molten metal poured into molds, often limiting detail and increasing porosity risks. Mastering fabrication techniques allows jewelers to create high-quality, durable platinum pieces with fine detailing and a superior finish.

Comparing Accuracy and Detail in Casting vs Fabrication

Platinum casting offers superior precision and intricate detail, allowing for complex designs with fine textures and consistent reproduction of delicate elements. Fabrication involves manually shaping and assembling platinum pieces, which can limit the level of detail and precision achievable compared to casting. While fabrication excels in creating bold, structural forms, casting remains the preferred method for high-accuracy, detailed platinum jewelry and art pieces.

Strength and Durability: Casting vs Fabrication Results

Platinum casting involves melting the metal and pouring it into molds, which can introduce microscopic porosity and internal stresses that slightly reduce strength and long-term durability. Fabrication, or hand-forging and assembling platinum, produces a denser and more homogenous material structure, resulting in superior tensile strength and resistance to wear and fatigue. Studies show fabricated platinum jewelry typically outperforms cast pieces in maintaining structural integrity under repeated stress and environmental exposure.

Design Flexibility with Casting and Fabrication

Platinum casting offers exceptional design flexibility by allowing intricate and complex shapes to be created with precise detail, making it ideal for custom and detailed jewelry pieces. In contrast, platinum fabrication involves manipulating metal sheets or wires, which limits design complexity but provides greater control for structural elements and simpler designs. Casting is preferred for organic, fluid forms, while fabrication suits geometric and architectural styles requiring sturdy construction.

Cost Implications: Casting Versus Fabrication Methods

Platinum casting typically involves higher initial costs due to the complexity of mold creation and the need for specialized equipment, but it allows for intricate designs with minimal material waste. Fabrication methods, such as hand-building or using pre-cut sheets, often reduce labor expenses and material loss but may limit design complexity and increase production time. Considering cost implications, casting can be more economical for large-scale or detailed pieces, while fabrication may be advantageous for simpler, custom designs requiring less upfront investment.

Common Applications for Each Platinum Technique

Platinum casting is commonly used for creating intricate jewelry designs, dental restorations, and industrial components that require precise detailing and complex shapes. Platinum fabrication, involving processes like cutting, welding, and soldering, is preferred for manufacturing custom jewelry pieces, watch parts, and electronic devices where structural integrity and strength are essential. Both techniques serve valuable roles in aerospace, automotive, and chemical industries, with casting favored for prototypes and fabrication for durable, finished products.

Choosing the Right Method for Your Platinum Project

Platinum casting offers intricate detail and complex shapes by pouring molten platinum into molds, ideal for custom jewelry or intricate designs requiring precision. Platinum fabrication involves manually shaping and assembling platinum pieces through cutting, soldering, and polishing, providing strength and control for simpler or structural projects. Selecting between casting and fabrication depends on project complexity, design detail, production volume, and budget constraints to ensure optimal results.

Platinum Casting vs Platinum Fabrication Infographic

materialdif.com

materialdif.com