Platinum group metals (PGMs) such as platinum, palladium, and rhodium exhibit superior corrosion resistance, high melting points, and exceptional catalytic properties compared to base metals like copper, iron, and aluminum. These attributes make PGMs essential in automotive catalytic converters, jewelry, and advanced industrial applications where durability and performance are critical. Base metals, while more abundant and cost-effective, lack the unique chemical stability and conductivity that define platinum group metals.

Table of Comparison

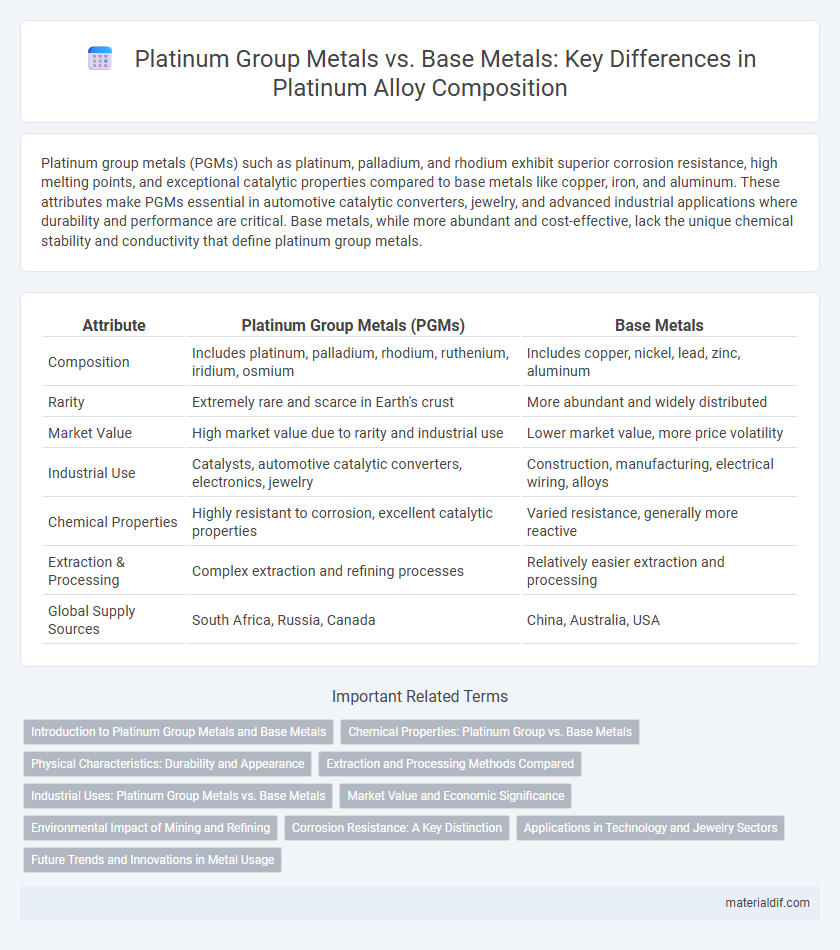

| Attribute | Platinum Group Metals (PGMs) | Base Metals |

|---|---|---|

| Composition | Includes platinum, palladium, rhodium, ruthenium, iridium, osmium | Includes copper, nickel, lead, zinc, aluminum |

| Rarity | Extremely rare and scarce in Earth's crust | More abundant and widely distributed |

| Market Value | High market value due to rarity and industrial use | Lower market value, more price volatility |

| Industrial Use | Catalysts, automotive catalytic converters, electronics, jewelry | Construction, manufacturing, electrical wiring, alloys |

| Chemical Properties | Highly resistant to corrosion, excellent catalytic properties | Varied resistance, generally more reactive |

| Extraction & Processing | Complex extraction and refining processes | Relatively easier extraction and processing |

| Global Supply Sources | South Africa, Russia, Canada | China, Australia, USA |

Introduction to Platinum Group Metals and Base Metals

Platinum Group Metals (PGMs) consist of six rare and valuable metals: platinum, palladium, rhodium, ruthenium, iridium, and osmium, known for their exceptional catalytic properties and resistance to corrosion. Base metals, including copper, nickel, zinc, and lead, are more abundant and primarily used in industrial applications such as electronics, construction, and manufacturing. Unlike PGMs, base metals have lower market values due to their widespread availability and less specialized uses.

Chemical Properties: Platinum Group vs. Base Metals

Platinum Group Metals (PGMs) such as platinum, palladium, and rhodium exhibit exceptional chemical inertness and resistance to oxidation compared to base metals like copper, nickel, and zinc, which are more prone to corrosion and chemical degradation. PGMs possess high catalytic activity and maintain stability at elevated temperatures, making them ideal for catalytic converters and industrial applications. In contrast, base metals have variable reactivity and generally lower melting points, limiting their utility in harsh chemical environments.

Physical Characteristics: Durability and Appearance

Platinum Group Metals (PGMs) such as platinum, palladium, and rhodium exhibit exceptional durability, including high corrosion resistance and wear resistance, compared to base metals like copper, nickel, and zinc. PGMs maintain a lustrous, silvery-white appearance that resists tarnishing, whereas base metals often oxidize or develop patinas over time. The superior hardness and stable surface finish of PGMs make them ideal for high-performance industrial applications and fine jewelry.

Extraction and Processing Methods Compared

Platinum Group Metals (PGMs) such as platinum, palladium, and rhodium require complex extraction techniques like flotation, smelting, and matte refining to separate them from sulfide ores, unlike base metals such as copper, zinc, and nickel which typically undergo simpler pyrometallurgical and hydrometallurgical processes. PGM extraction often involves high-temperature operations and specialized chemical treatments to achieve the purity necessary for catalytic and industrial applications, whereas base metals are commonly recovered using less energy-intensive methods like leaching and solvent extraction. The intricate refining stages for PGMs include chlorine leaching and precipitation steps that are not generally required for base metals, reflecting the higher value and rarity of PGMs.

Industrial Uses: Platinum Group Metals vs. Base Metals

Platinum Group Metals (PGMs), including platinum, palladium, rhodium, and iridium, are highly valued in industrial applications for their superior catalytic properties, corrosion resistance, and high melting points, making them essential in automotive catalytic converters, chemical processing, and electronics. Base metals such as copper, nickel, and zinc are primarily used for structural components, electrical wiring, and galvanization due to their abundant availability and lower cost, but they lack the catalytic efficiency and durability of PGMs in specialized industrial processes. The unique chemical stability and conductivity of PGMs position them as critical materials in emerging technologies like fuel cells and advanced electronics, where base metals cannot meet performance requirements.

Market Value and Economic Significance

Platinum Group Metals (PGMs) such as platinum, palladium, and rhodium hold significantly higher market value compared to base metals like copper, nickel, and zinc due to their rarity and extensive industrial applications, particularly in automotive catalytic converters and electronics. The economic significance of PGMs extends beyond traditional commodities, as they are critical for green technologies, including fuel cells and hydrogen production, driving demand in emerging renewable energy sectors. In contrast, base metals are primarily valued for construction, manufacturing, and infrastructure, with more stable but lower price points influenced by global economic cycles.

Environmental Impact of Mining and Refining

Platinum Group Metals (PGMs) mining generally results in lower greenhouse gas emissions compared to Base Metals due to more efficient ore processing techniques and smaller-scale extraction operations. The refining of PGMs involves fewer toxic by-products and less water contamination, whereas Base Metals mining often generates significant sulfur dioxide emissions and acid mine drainage, posing greater environmental risks. Recycling rates for PGMs are higher, reducing the need for new mining activities, while Base Metals rely more heavily on extensive and invasive mining practices that contribute to habitat destruction and soil degradation.

Corrosion Resistance: A Key Distinction

Platinum Group Metals (PGMs) such as platinum, palladium, and rhodium exhibit exceptional corrosion resistance compared to base metals like iron, copper, and aluminum, making them ideal for harsh environments. This superior corrosion resistance is due to the high chemical stability and inertness of PGMs, which prevents oxidation and degradation over time. As a result, PGMs are widely used in catalytic converters, jewelry, and high-precision industrial applications where durability and longevity are critical.

Applications in Technology and Jewelry Sectors

Platinum Group Metals (PGMs), including platinum, palladium, and rhodium, offer superior catalytic properties essential for automotive catalytic converters and advanced electronics, making them indispensable in high-tech applications compared to base metals like copper and nickel. In the jewelry sector, platinum's unparalleled durability and hypoallergenic nature provide a premium alternative to more common base metals such as brass or stainless steel, ensuring longevity and luxury appeal. The high melting points and corrosion resistance of PGMs drive their critical use in both cutting-edge technology manufacturing and exclusive, long-lasting jewelry designs.

Future Trends and Innovations in Metal Usage

Platinum Group Metals (PGMs) are expected to drive future innovations through their critical role in catalytic converters, hydrogen fuel cells, and advanced electronics, distinguishing them from base metals like copper and nickel, which primarily support structural and electrical applications. Emerging trends highlight PGMs' superior catalytic efficiency and corrosion resistance, fostering their adoption in sustainable technologies and clean energy solutions. Investment in refining technologies and recycling processes for PGMs is increasing to meet growing demand while mitigating supply risks associated with scarcity and geopolitical factors.

Platinum Group Metals vs Base Metals Infographic

materialdif.com

materialdif.com