Lead core wire offers superior durability and resistance to corrosion compared to copper core wire, making it ideal for harsh environments. It provides excellent shielding effectiveness against electromagnetic interference while maintaining flexibility and strength. Copper core wire, however, is more conductive and less expensive, making it suitable for applications requiring high electrical performance with budget constraints.

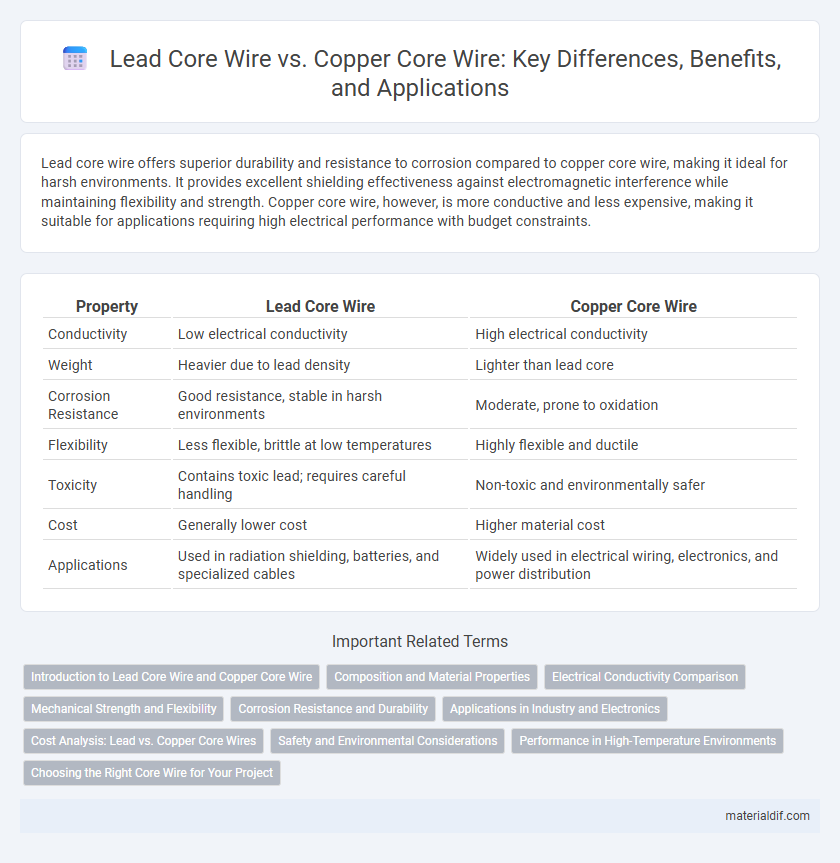

Table of Comparison

| Property | Lead Core Wire | Copper Core Wire |

|---|---|---|

| Conductivity | Low electrical conductivity | High electrical conductivity |

| Weight | Heavier due to lead density | Lighter than lead core |

| Corrosion Resistance | Good resistance, stable in harsh environments | Moderate, prone to oxidation |

| Flexibility | Less flexible, brittle at low temperatures | Highly flexible and ductile |

| Toxicity | Contains toxic lead; requires careful handling | Non-toxic and environmentally safer |

| Cost | Generally lower cost | Higher material cost |

| Applications | Used in radiation shielding, batteries, and specialized cables | Widely used in electrical wiring, electronics, and power distribution |

Introduction to Lead Core Wire and Copper Core Wire

Lead core wire consists of a lead core surrounded by copper or other metals, offering excellent corrosion resistance and high density, making it suitable for applications requiring weight and shielding. Copper core wire features a solid copper conductor known for superior electrical conductivity, flexibility, and durability, commonly used in electrical wiring and electronics. The choice between lead core and copper core wire depends on the application's need for conductivity, corrosion resistance, and mechanical strength.

Composition and Material Properties

Lead core wire consists primarily of a lead center, known for its high density and excellent malleability, making it suitable for applications requiring weight and flexibility. Copper core wire features a copper center, valued for its superior electrical conductivity, tensile strength, and corrosion resistance. The choice between lead and copper core wires depends on the specific requirements of conductivity, durability, and material flexibility in the intended application.

Electrical Conductivity Comparison

Lead core wire exhibits significantly lower electrical conductivity compared to copper core wire, making copper the preferred choice for efficient electrical applications. Copper's conductivity is approximately 5.8 x 10^7 S/m, while lead's conductivity is roughly 4.8 x 10^6 S/m, illustrating copper's superior ability to transmit electric current. This substantial difference in conductivity impacts energy efficiency, heating, and overall performance in wiring systems.

Mechanical Strength and Flexibility

Lead core wire offers superior flexibility and excellent corrosion resistance, making it ideal for applications requiring frequent bending and movement. Copper core wire provides higher mechanical strength and better conductivity but is less flexible, which can limit its use in dynamic environments. Selecting between lead and copper core wires depends on balancing the need for mechanical durability with flexibility requirements in electrical and structural applications.

Corrosion Resistance and Durability

Lead core wire offers superior corrosion resistance compared to copper core wire, making it ideal for harsh environments where exposure to moisture and chemicals is prevalent. Its inherent durability extends the lifespan of applications such as electrical grounding and cable shielding, reducing maintenance needs. Copper core wire, while excellent for conductivity, tends to oxidize faster, leading to potential performance degradation over time.

Applications in Industry and Electronics

Lead core wire offers superior corrosion resistance and is widely used in applications requiring high durability and shielding, such as in radiation therapy equipment and batteries. Copper core wire excels in electrical conductivity and flexibility, making it ideal for electronics, telecommunications, and power transmission systems. Industry applications prioritize material choice based on performance needs, with lead core wires favored in hazardous environments and copper core wires dominant in efficient electrical circuits.

Cost Analysis: Lead vs. Copper Core Wires

Lead core wire typically offers a lower material cost compared to copper core wire due to lead's abundance and cheaper extraction process. Copper core wire, while more expensive, provides superior electrical conductivity and durability, which may justify the higher initial investment in applications requiring long-term performance. Cost analysis must account for both upfront material expenses and lifecycle benefits when choosing between lead and copper core wires.

Safety and Environmental Considerations

Lead core wire poses significant environmental risks due to lead's toxicity and potential for soil and water contamination, making it less safe for human health compared to copper core wire. Copper core wire is favored for safety and environmental reasons because copper is non-toxic, recyclable, and environmentally friendly while maintaining excellent electrical conductivity. Regulatory standards increasingly restrict the use of lead in wiring to minimize lead exposure and its harmful impact on ecosystems.

Performance in High-Temperature Environments

Lead core wire exhibits superior performance in high-temperature environments due to its excellent thermal stability and resistance to oxidation, making it ideal for applications involving repeated thermal cycling. Copper core wire, while providing excellent electrical conductivity, tends to suffer from higher thermal expansion and potential degradation under extreme heat, which can compromise reliability. For high-temperature applications, lead core wire offers enhanced durability and consistent performance, maintaining structural integrity and conductivity better than copper core alternatives.

Choosing the Right Core Wire for Your Project

Lead core wire offers superior flexibility and excellent corrosion resistance, making it ideal for applications requiring durability in harsh environments. Copper core wire provides exceptional electrical conductivity and thermal performance, suitable for projects demanding efficient energy transfer. Selecting the right core wire depends on project requirements such as environmental exposure, conductivity needs, and mechanical flexibility.

Lead Core Wire vs Copper Core Wire Infographic

materialdif.com

materialdif.com