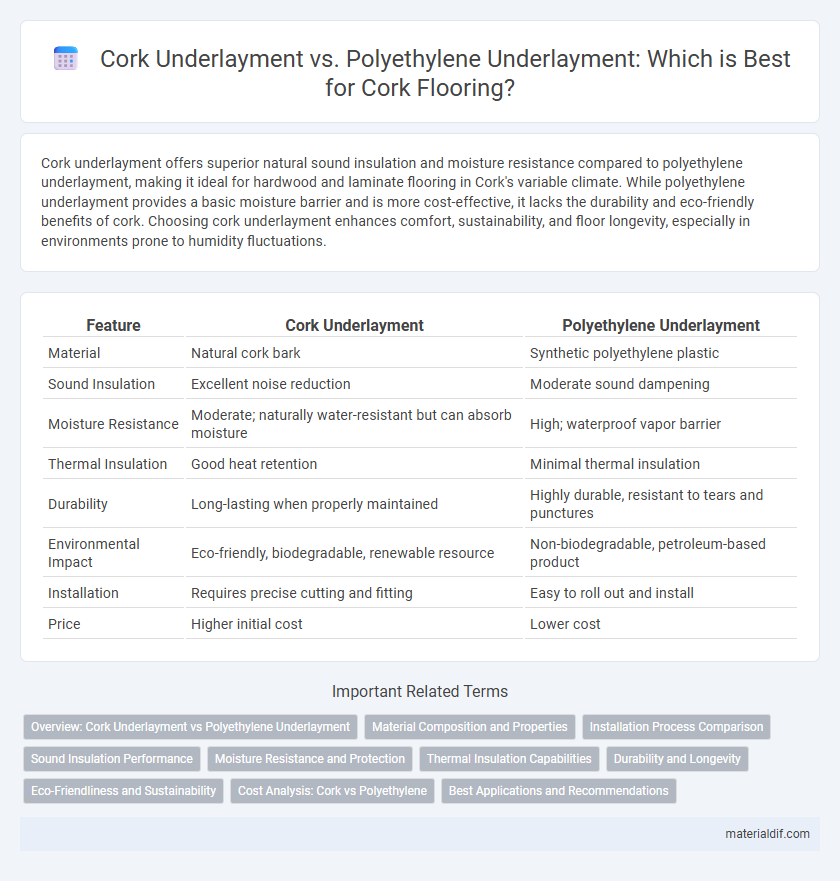

Cork underlayment offers superior natural sound insulation and moisture resistance compared to polyethylene underlayment, making it ideal for hardwood and laminate flooring in Cork's variable climate. While polyethylene underlayment provides a basic moisture barrier and is more cost-effective, it lacks the durability and eco-friendly benefits of cork. Choosing cork underlayment enhances comfort, sustainability, and floor longevity, especially in environments prone to humidity fluctuations.

Table of Comparison

| Feature | Cork Underlayment | Polyethylene Underlayment |

|---|---|---|

| Material | Natural cork bark | Synthetic polyethylene plastic |

| Sound Insulation | Excellent noise reduction | Moderate sound dampening |

| Moisture Resistance | Moderate; naturally water-resistant but can absorb moisture | High; waterproof vapor barrier |

| Thermal Insulation | Good heat retention | Minimal thermal insulation |

| Durability | Long-lasting when properly maintained | Highly durable, resistant to tears and punctures |

| Environmental Impact | Eco-friendly, biodegradable, renewable resource | Non-biodegradable, petroleum-based product |

| Installation | Requires precise cutting and fitting | Easy to roll out and install |

| Price | Higher initial cost | Lower cost |

Overview: Cork Underlayment vs Polyethylene Underlayment

Cork underlayment offers superior natural insulation, sound absorption, and eco-friendly benefits compared to polyethylene underlayment, which primarily provides moisture protection and durability. Cork's renewable, biodegradable properties enhance indoor air quality and thermal comfort, while polyethylene underlayment excels in resistance to mold, mildew, and vapor transmission. Choosing between cork and polyethylene underlayments depends on prioritizing environmental sustainability, moisture barrier effectiveness, or acoustic performance in flooring applications.

Material Composition and Properties

Cork underlayment is composed of natural cork granules, providing excellent thermal insulation, moisture resistance, and soundproofing due to its cellular structure. Polyethylene underlayment, made from synthetic plastic film, offers superior moisture vapor barriers and is highly durable against water infiltration but lacks the natural insulation properties of cork. Both materials serve as effective underlayments, with cork excelling in eco-friendliness and comfort, while polyethylene prioritizes impermeability and longevity in moisture-prone environments.

Installation Process Comparison

Cork underlayment offers a straightforward installation process with natural flexibility, allowing it to conform easily to uneven subfloors and requiring minimal adhesive application. Polyethylene underlayment, typically thinner and less compressible, demands precise cutting and taping to ensure moisture barriers are intact during installation. Both materials require careful surface preparation, but cork's resilience can reduce installation time on irregular surfaces compared to polyethylene options.

Sound Insulation Performance

Cork underlayment provides superior sound insulation performance compared to polyethylene underlayment due to its natural density and cellular structure, which effectively absorbs and dampens impact and airborne noise. Cork reduces sound transmission by up to 60%, making it an ideal choice for flooring in multi-unit buildings or areas requiring enhanced acoustic comfort. Polyethylene underlayment, while moisture-resistant, offers minimal soundproofing benefits and is less effective at reducing noise levels.

Moisture Resistance and Protection

Cork underlayment offers excellent natural moisture resistance due to its cellular structure, which repels water while allowing breathability, reducing the risk of mold and mildew. Polyethylene underlayment provides a robust moisture barrier as a synthetic vapor barrier, effectively preventing water vapor transmission and protecting subfloors from moisture damage. Choosing between cork and polyethylene underlayment depends on the specific needs for moisture management and subfloor protection in the installation environment.

Thermal Insulation Capabilities

Cork underlayment offers superior thermal insulation due to its natural cellular structure, which effectively reduces heat transfer and maintains indoor temperature stability. Polyethylene underlayment, while moisture-resistant, provides minimal thermal insulation compared to cork. Homeowners prioritizing energy efficiency will benefit more from cork's enhanced thermal performance in flooring systems.

Durability and Longevity

Cork underlayment offers superior durability and natural resistance to mold, mildew, and compression, ensuring long-lasting performance in flooring installations. Polyethylene underlayment, while cost-effective and moisture-resistant, tends to compress over time and lacks the resilience of cork, reducing its lifespan. Choosing cork underlayment in Cork homes can enhance longevity and maintain consistent structural integrity under various environmental conditions.

Eco-Friendliness and Sustainability

Cork underlayment is highly eco-friendly, made from natural, renewable cork oak bark that is biodegradable and sustainably harvested without harming trees. Polyethylene underlayment, typically derived from non-renewable petroleum-based plastics, poses environmental concerns due to its slower decomposition and reliance on fossil fuels. Choosing cork underlayment supports sustainability goals by reducing carbon footprint and promoting the use of renewable materials in flooring installations.

Cost Analysis: Cork vs Polyethylene

Cork underlayment generally costs between $2.50 and $4.00 per square foot, making it a pricier option compared to polyethylene underlayment, which typically ranges from $0.10 to $0.50 per square foot. While cork offers superior sound insulation and natural moisture resistance, polyethylene provides a more budget-friendly solution with effective vapor barrier properties. Evaluating long-term durability and environmental impact can influence the overall cost-effectiveness in cork flooring projects.

Best Applications and Recommendations

Cork underlayment offers superior sound insulation and moisture resistance, making it ideal for hardwood and tile flooring in residential settings where comfort and durability are priorities. Polyethylene underlayment excels as a vapor barrier, best suited for concrete subfloors and areas prone to high moisture, such as basements and ground floors. For optimal flooring performance, choose cork underlayment in quieter, low-moisture environments, while polyethylene underlayment is recommended for moisture-prone areas requiring effective vapor protection.

Cork Underlayment vs Polyethylene Underlayment Infographic

materialdif.com

materialdif.com