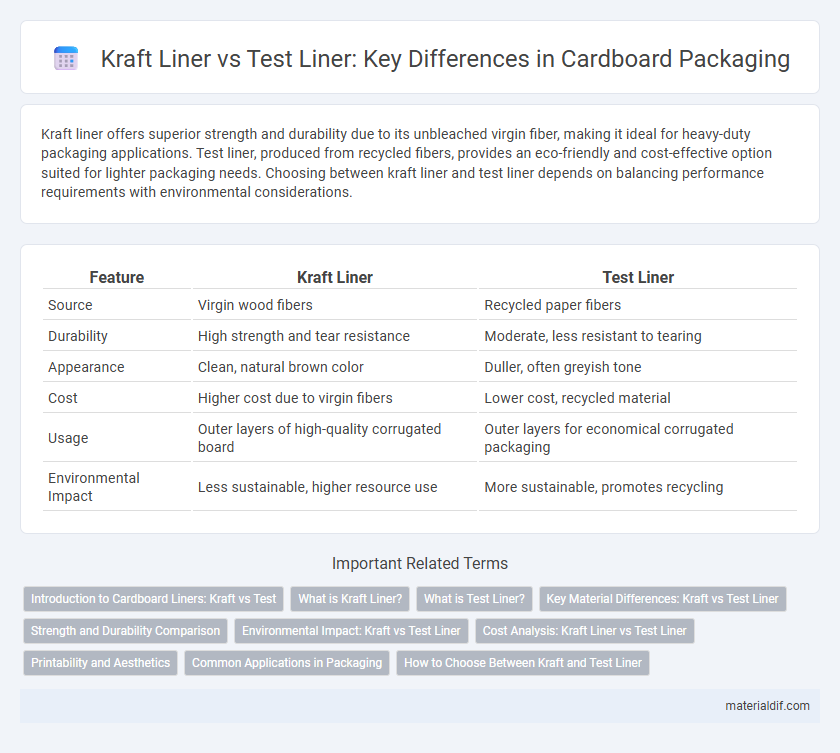

Kraft liner offers superior strength and durability due to its unbleached virgin fiber, making it ideal for heavy-duty packaging applications. Test liner, produced from recycled fibers, provides an eco-friendly and cost-effective option suited for lighter packaging needs. Choosing between kraft liner and test liner depends on balancing performance requirements with environmental considerations.

Table of Comparison

| Feature | Kraft Liner | Test Liner |

|---|---|---|

| Source | Virgin wood fibers | Recycled paper fibers |

| Durability | High strength and tear resistance | Moderate, less resistant to tearing |

| Appearance | Clean, natural brown color | Duller, often greyish tone |

| Cost | Higher cost due to virgin fibers | Lower cost, recycled material |

| Usage | Outer layers of high-quality corrugated board | Outer layers for economical corrugated packaging |

| Environmental Impact | Less sustainable, higher resource use | More sustainable, promotes recycling |

Introduction to Cardboard Liners: Kraft vs Test

Kraft liners are made from virgin wood fibers, providing superior strength, durability, and resistance to moisture, which makes them ideal for heavy-duty packaging applications. Test liners consist mainly of recycled fibers, offering cost-effective and environmentally friendly solutions but with comparatively lower strength and durability. Both kraft and test liners serve as essential components in cardboard production, selected based on the balance between performance needs and budget constraints.

What is Kraft Liner?

Kraft liner is a high-strength paperboard used primarily for the outer layers of corrugated cardboard, made from virgin wood fibers processed through the kraft pulping method. It offers superior durability, tear resistance, and moisture resistance compared to test liner, which is typically made from recycled fibers. Kraft liner is essential in packaging applications requiring enhanced structural integrity and protection.

What is Test Liner?

Test liner is a type of recycled paperboard used primarily in the production of corrugated packaging and cardboard boxes, made from a blend of recovered fibers including old corrugated containers and mixed office waste. It provides a cost-effective, eco-friendly alternative to virgin Kraft liner while offering sufficient strength and durability for secondary packaging layers. Test liner's performance depends on its fiber content and manufacturing process, making it suitable for applications where high aesthetic quality and moisture resistance are less critical.

Key Material Differences: Kraft vs Test Liner

Kraft liner is produced from virgin wood fibers, offering superior strength, durability, and tear resistance compared to test liner, which primarily uses recycled fibers. The high lignin content in kraft liner results in enhanced stiffness and moisture resistance, making it ideal for heavy-duty packaging applications. Test liner, while more cost-effective and environmentally friendly due to its recycled content, generally exhibits lower tensile strength and less uniformity in surface finish.

Strength and Durability Comparison

Kraft liner exhibits superior strength and durability compared to test liner due to its higher quality virgin fibers and fewer recycled materials, resulting in enhanced tear resistance and load-bearing capacity. Test liner, primarily composed of recycled fibers, offers moderate durability suitable for less demanding packaging but may degrade faster under pressure or moisture. Selecting kraft liner ensures prolonged performance in heavy-duty applications, while test liner serves cost-effective needs with moderate strength requirements.

Environmental Impact: Kraft vs Test Liner

Kraft liner, made from virgin wood fibers, offers higher strength and durability but involves more energy-intensive production, leading to a larger carbon footprint compared to test liner, which utilizes recycled fibers and reduces waste. Test liner's reliance on recovered paper significantly lowers resource consumption and greenhouse gas emissions, promoting a circular economy within the cardboard industry. Selecting test liner over kraft liner can contribute to more sustainable packaging solutions by minimizing deforestation and enhancing recyclability.

Cost Analysis: Kraft Liner vs Test Liner

Kraft liner, made from virgin wood fibers, generally incurs higher production costs compared to test liner, which is composed primarily of recycled fibers, making it more cost-effective for packaging applications. The superior strength and durability of kraft liner justify its premium price in industries requiring heavy-duty performance, while test liner offers a budget-friendly alternative for less demanding uses. Analyzing procurement and lifecycle expenses reveals that test liner can reduce overall material costs by up to 30% versus kraft liner in high-volume orders.

Printability and Aesthetics

Kraft liner offers superior printability due to its smooth surface and consistent fiber quality, resulting in sharp, high-resolution graphics ideal for premium packaging. Test liner, while cost-effective and recyclable, often has a rougher texture and varies in color, which can affect print clarity and limit aesthetic appeal. Choosing kraft liner enhances visual presentation and brand impact, especially for detailed designs and vibrant colors.

Common Applications in Packaging

Kraft liner is predominantly used in packaging for its high strength and durability, making it ideal for heavy-duty boxes and industrial containers. Test liner, derived from recycled fibers, is commonly applied in retail packaging, folding cartons, and secondary packaging where cost-effectiveness and printability are essential. Both materials contribute to sustainable packaging solutions, with Kraft liner offering superior performance and Test liner providing an economical alternative.

How to Choose Between Kraft and Test Liner

Choosing between Kraft liner and Test liner depends primarily on the required strength and cost considerations for cardboard production. Kraft liner offers superior tear resistance and durability due to its higher-quality virgin fibers, making it ideal for heavy-duty packaging needs. Test liner, made from recycled fibers, provides a more economical option suitable for lightweight or less demanding applications where environmental sustainability is also a priority.

Kraft liner vs Test liner Infographic

materialdif.com

materialdif.com