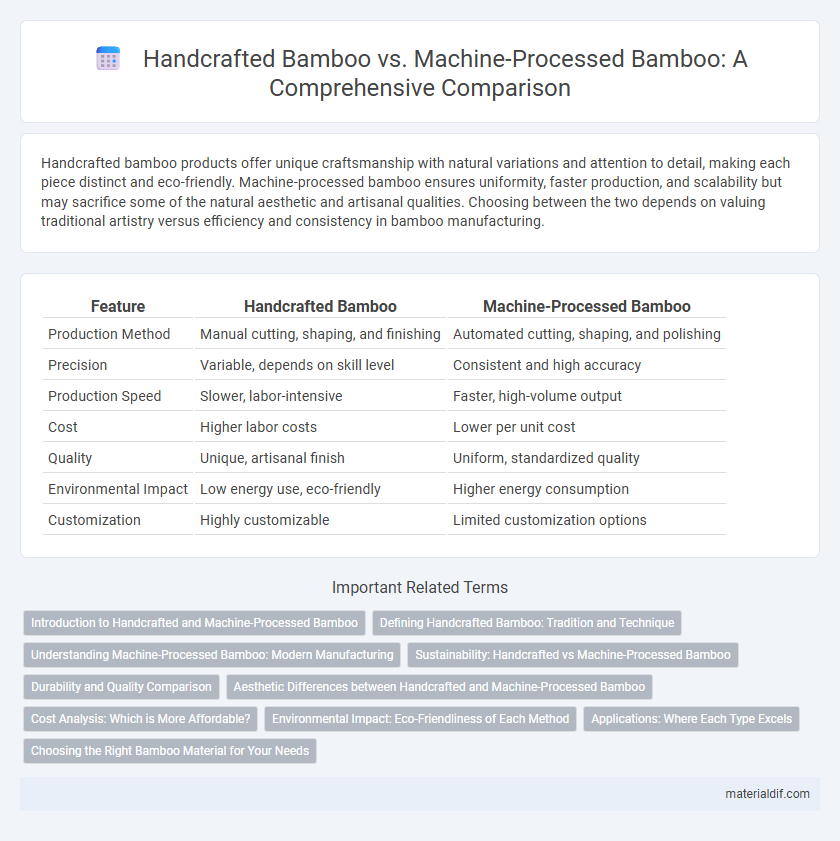

Handcrafted bamboo products offer unique craftsmanship with natural variations and attention to detail, making each piece distinct and eco-friendly. Machine-processed bamboo ensures uniformity, faster production, and scalability but may sacrifice some of the natural aesthetic and artisanal qualities. Choosing between the two depends on valuing traditional artistry versus efficiency and consistency in bamboo manufacturing.

Table of Comparison

| Feature | Handcrafted Bamboo | Machine-Processed Bamboo |

|---|---|---|

| Production Method | Manual cutting, shaping, and finishing | Automated cutting, shaping, and polishing |

| Precision | Variable, depends on skill level | Consistent and high accuracy |

| Production Speed | Slower, labor-intensive | Faster, high-volume output |

| Cost | Higher labor costs | Lower per unit cost |

| Quality | Unique, artisanal finish | Uniform, standardized quality |

| Environmental Impact | Low energy use, eco-friendly | Higher energy consumption |

| Customization | Highly customizable | Limited customization options |

Introduction to Handcrafted and Machine-Processed Bamboo

Handcrafted bamboo involves traditional techniques where artisans skillfully manipulate bamboo using manual tools to create unique, intricate designs that emphasize natural textures and sustainability. Machine-processed bamboo relies on industrial machinery for large-scale production, enhancing precision, uniformity, and efficiency in shaping and treating bamboo materials. Both methods impact the durability and aesthetic qualities of bamboo products, catering to different market demands and environmental considerations.

Defining Handcrafted Bamboo: Tradition and Technique

Handcrafted bamboo involves skilled artisans meticulously shaping and assembling bamboo using traditional tools and techniques passed down through generations, ensuring unique textures and intricate designs. This process emphasizes natural material preservation and sustainable practices, enhancing the bamboo's strength and aesthetic appeal. In contrast to machine-processed bamboo, handcrafted items often showcase superior craftsmanship, cultural heritage, and environmental responsibility.

Understanding Machine-Processed Bamboo: Modern Manufacturing

Machine-processed bamboo involves advanced techniques such as steam bending, CNC cutting, and chemical treatments that enhance durability and uniformity in products. This manufacturing method enables large-scale production with precise dimensions, reducing material waste and optimizing resource efficiency. Modern machine processing transforms raw bamboo into versatile components used in furniture, flooring, and construction with consistent quality and structural integrity.

Sustainability: Handcrafted vs Machine-Processed Bamboo

Handcrafted bamboo products often utilize traditional techniques that minimize waste and reduce energy consumption, fostering greater sustainability compared to machine-processed bamboo, which relies heavily on electricity and industrial machinery. Bamboo's rapid growth rate and carbon sequestration properties enhance its sustainability credentials, but handcrafted methods amplify environmental benefits through careful material use and reduced chemical treatments. Machine processing can increase production scale but may involve higher emissions and resource input, impacting the overall ecological footprint.

Durability and Quality Comparison

Handcrafted bamboo products often showcase superior durability due to meticulous attention to detail and traditional techniques that enhance the natural strength of bamboo fibers. Machine-processed bamboo, while consistent in quality, may compromise durability because of uniform cutting and assembly methods that can weaken structural integrity. The artisanal approach allows for selective material use and precision crafting, resulting in higher quality bamboo items designed to last longer in various applications.

Aesthetic Differences between Handcrafted and Machine-Processed Bamboo

Handcrafted bamboo showcases unique textures and natural imperfections that highlight the artisan's skill, creating a warm, organic aesthetic. Machine-processed bamboo offers uniformity and precision, resulting in a sleek, consistent appearance ideal for modern designs. The choice between handcrafted and machine-processed bamboo ultimately shapes the visual character and tactile experience of bamboo products.

Cost Analysis: Which is More Affordable?

Handcrafted bamboo products typically incur higher costs due to labor-intensive processes and artisanal skills, resulting in unique but pricier items. Machine-processed bamboo benefits from automation and mass production, significantly reducing manufacturing expenses and offering more affordable options at scale. Cost analysis shows machine-processed bamboo is generally more budget-friendly for large quantities, while handcrafted bamboo appeals to niche markets valuing craftsmanship despite higher prices.

Environmental Impact: Eco-Friendliness of Each Method

Handcrafted bamboo production typically minimizes energy consumption and reduces chemical use, resulting in a lower carbon footprint compared to machine-processed bamboo, which often relies on electricity and industrial chemicals that contribute to pollution. The artisanal method preserves the natural structure of bamboo fibers, enhancing biodegradability and reducing waste, while machine processing can generate more by-products and synthetic residues. Choosing handcrafted bamboo supports sustainable practices by maintaining ecosystem balance and promoting renewable resource utilization.

Applications: Where Each Type Excels

Handcrafted bamboo excels in artisanal applications such as furniture, decorative items, and traditional crafts, where precision and intricate detailing are essential. Machine-processed bamboo is ideal for large-scale industrial uses, including flooring, paneling, and construction materials, offering consistency and durability. Each type's unique processing method aligns with specific functional requirements, making handcrafted bamboo preferable for customized aesthetics and machine-processed bamboo superior for structural reliability.

Choosing the Right Bamboo Material for Your Needs

Handcrafted bamboo offers unique durability and aesthetic appeal due to traditional techniques that preserve natural fibers, making it ideal for artisanal furniture and eco-friendly crafts. Machine-processed bamboo provides uniformity and scalability, suitable for mass production in construction or flooring where consistency and cost-efficiency are critical. Selecting the right bamboo material depends on balancing craftsmanship, budget, and application requirements to optimize performance and longevity.

Handcrafted bamboo vs Machine-processed bamboo Infographic

materialdif.com

materialdif.com